Water-borne sizing agent for carbon fiber and preparation method and sizing method thereof

A water-based, carbon fiber technology, applied in the field of fiber manufacturing, can solve the problems of poor bonding between carbon fiber and resin interface, easy residue of resin on guide rollers, easy volatilization of organic solvents, etc., and achieves excellent static stability and post-processing performance Improved, good interface adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

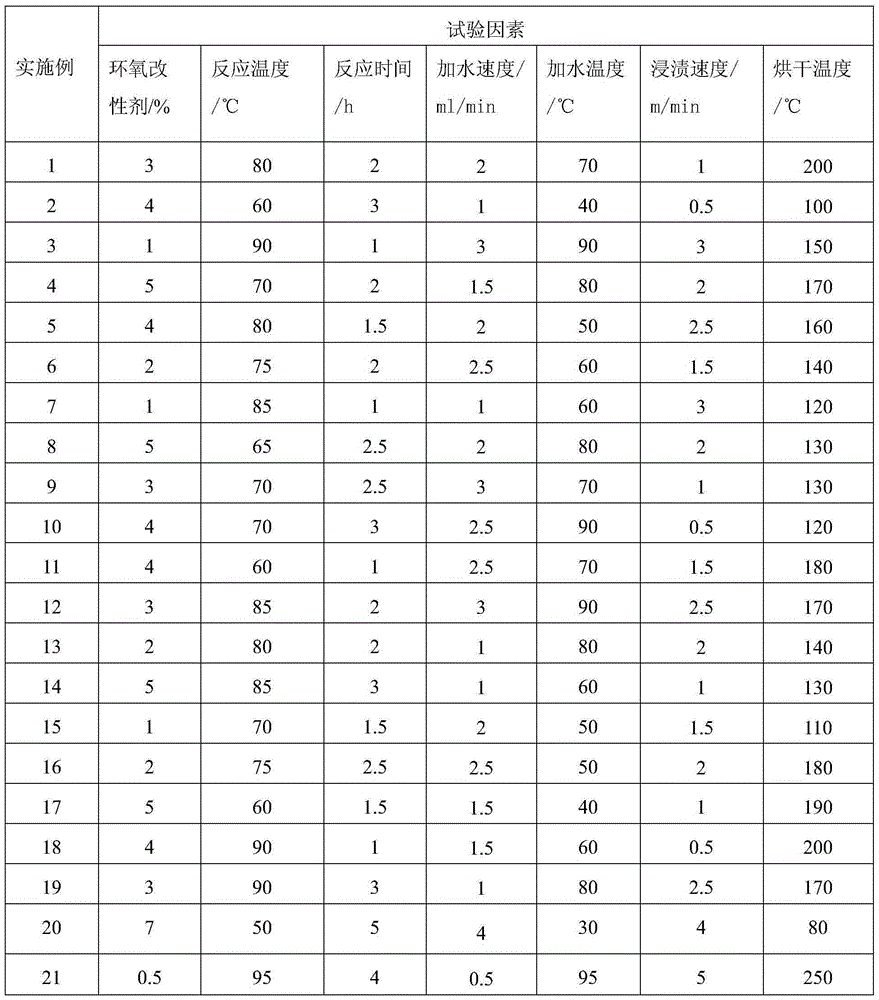

Embodiment 1

[0034] Step 1, prepare modified epoxy resin: put p-aminobenzenesulfonic acid and bisphenol A type epoxy resin E-51 with a mass ratio of 1:1 in the reaction kettle and stir at a stirring speed of 200-500r / min. React under the condition of 60°C for 3 hours to obtain anion-modified epoxy resin.

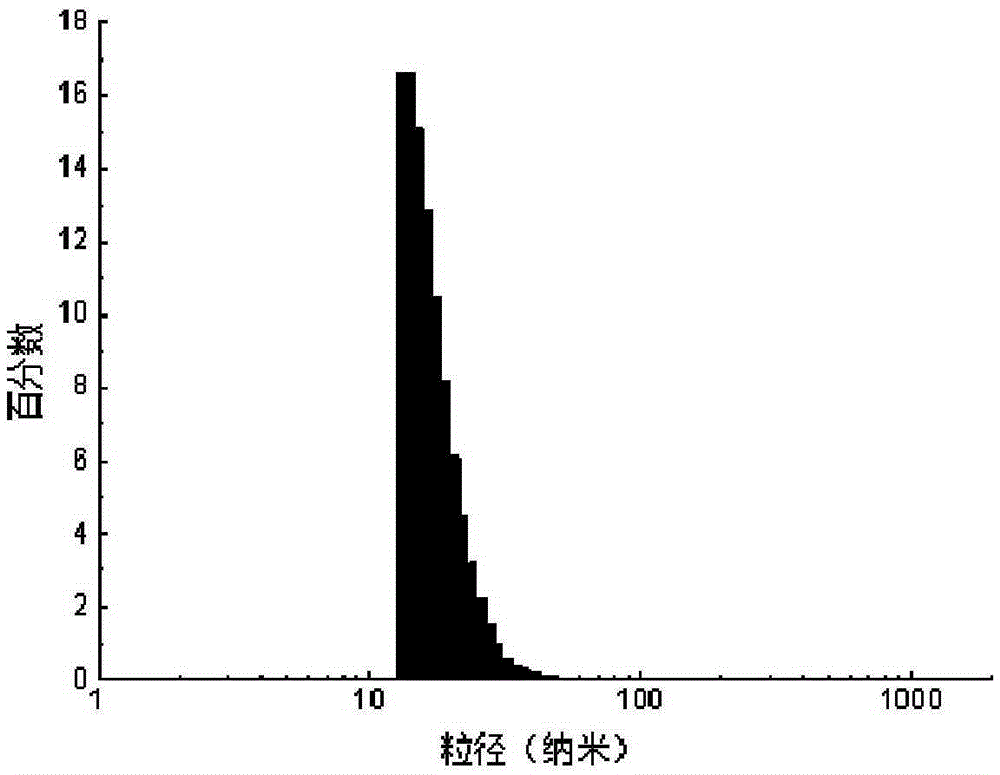

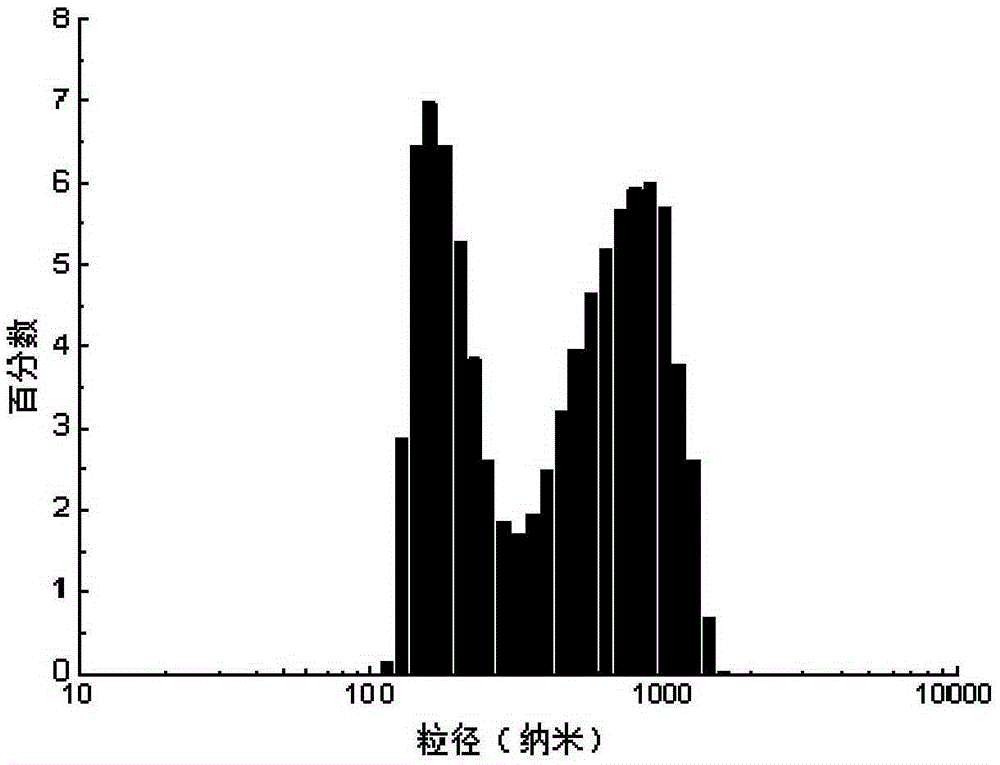

[0035] Step 2, adding deionized water dropwise: adding 30% deionized water dropwise to the modified epoxy resin at a rate of 1 mL / min. Emulsification with water: Add 50-150mL of deionized water dropwise at a rate of 1-3mL / min to the prepared modified epoxy resin under the condition of stirring at a temperature of 40-90°C and a rotation speed of 200-500r / min until the phase transition occurs.

[0036]Step 3, add additives: Add dropwise 0.05% polydimethylsiloxane, 0.5% sodium dodecylbenzene sulfonate, 0.03% polyoxyethylene fatty alcohol sulfate to the water-based epoxy resin emulsion prepared in step 2 , 0.05% ethanol, 0.06% ethyl cellulose, 0.1% acrylic resin, and stirred for 5-15 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com