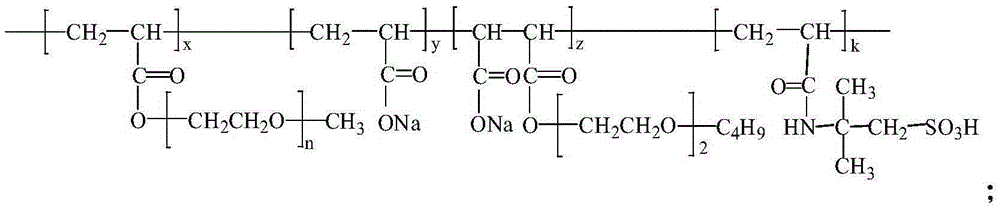

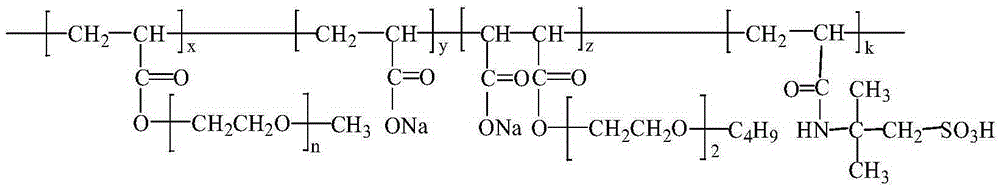

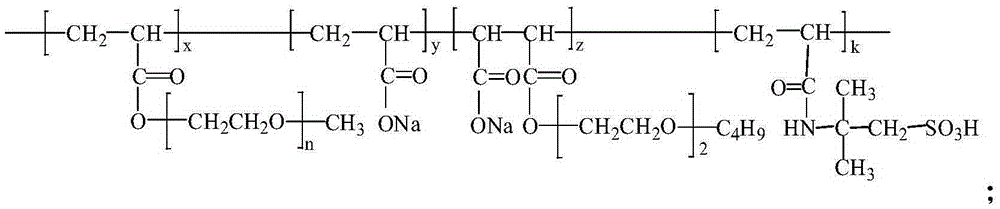

Multi-functional high-performance reduction material of polycarboxylic acid series and preparation method thereof

A multi-functional, high-performance technology, applied in the field of building materials, can solve problems such as poor operability, complex synthesis process, and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 2-acrylamido-2-methylpropanesulfonic acid solution into a four-necked glass flask, pass nitrogen to deoxygenate, raise the temperature to 55°C~85°C, and fully stir to dissolve, slowly add polyethylene dropwise within 2~4h Glycol monomethyl ether acrylate, acrylic acid, diethylene glycol monobutyl ether maleic anhydride monoester mixed solution and initiator solution, keep the temperature at 55℃~85℃ for 1~2h after dropping, add the catalyst at 55℃~100 After reacting at ℃ for 1-2 hours, carry out vacuum filtration for 2 hours, cool to room temperature after the reaction, and then use NaOH solution with mass fraction w(NaOH)=30% to adjust pH=7 and discharge the material, a multifunctional high-performance polymer can be obtained. Carboxylic acid shrinkage reducing material.

[0024] The catalyst is a composite catalyst of p-toluenesulfonic acid and concentrated hydrochloric acid, the amount of which is 6% of the total mass of the reaction monomers, and the mass ratio o...

Embodiment 2

[0033] It is basically the same as Example 1, the difference is:

[0034] in the water-reducing group Among them, n=35, x is 3, y is 5, z is 10, and k is 2.

[0035] The catalyst is a composite catalyst of p-toluenesulfonic acid and concentrated hydrochloric acid, the amount of which is 9% of the total mass of the reaction monomers, and the mass ratio of p-toluenesulfonic acid and concentrated hydrochloric acid is 1.4:1.

[0036] The molar ratio of polyethylene glycol monomethyl ether acrylate, acrylic acid, 2-acrylamido-2-methylpropanesulfonic acid and diethylene glycol monobutyl ether maleic anhydride monoester is 0.35:1:0.30:1.

[0037] The initiator is potassium persulfate-ascorbic acid composite initiator, its consumption is 4% of the total mass of the reaction monomer, and the mass ratio of potassium persulfate to ascorbic acid is 1:2.

Embodiment 3

[0039] Basically the same as Example 1, the difference is:

[0040] in the water-reducing group Among them, n=10, x is 5, y is 25, z is 10, and k is 8.

[0041] The catalyst is a p-toluenesulfonic acid catalyst, and its consumption is 9% of the total mass of the reaction monomers.

[0042] The molar ratio of polyethylene glycol monomethyl ether acrylate, acrylic acid, 2-acrylamido-2-methylpropanesulfonic acid and diethylene glycol monobutyl ether maleic anhydride monoester is 0.50:2.5:0.75:1.

[0043] The initiator is a potassium persulfate initiator, and its consumption is 10% of the total mass of the reaction monomers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com