Imidazole compound, preparation method and thermosetting composition containing imidazole compound

An imidazole compound and compound technology are applied in the field of imidazole compounds and compositions using the compounds to achieve the effects of high strength, high toughness and excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

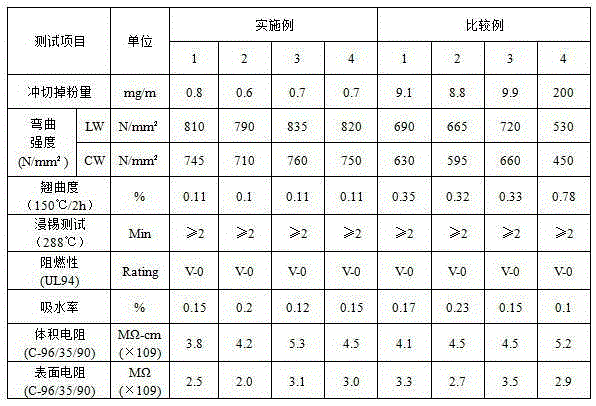

Examples

Embodiment 2

[0041] Take 2% imidazole and 98% polymethyl methacrylate by weight percentage, respectively dissolve imidazole and polymethyl methacrylate in methyl formamide solvent, mix the two solutions and heat and stir to produce For the copolymerization reaction, the heating temperature is 70° C., the stirring speed is 500 rpm, and the copolymerization reaction time is 50 minutes to obtain an imidazole compound solution containing polymethyl methacrylate groups.

Embodiment 3

[0043] Get 4% imidazole by weight percentage, and 96% phenoxy resin, dissolve imidazole and phenoxy resin in methyl formamide solvent respectively, after two kinds of solutions are mixed, heat and stir to produce copolymerization reaction, heating temperature is 80° C., the stirring speed is 400 rpm, and the copolymerization reaction time is 80 minutes to obtain an imidazole compound solution containing phenoxy resin groups.

[0044] Imidazole compound production embodiment four:

[0045] Take 6% imidazole, 40% nitrile rubber, 30% polymethyl methacrylate and 24% phenoxy resin by weight percentage, and dissolve the above-mentioned substances in a mixed solvent of butanone, toluene, and propylene glycol methyl ether respectively In the process, the above solutions are mixed and then heated and stirred to produce a copolymerization reaction. The heating temperature is 80°C, the stirring speed is 200 rpm, and the copolymerization reaction time is 80 minutes. Group and imidazole c...

Embodiment 1

[0093] 10 mass parts of the imidazole compound containing the nitrile rubber group and 15 mass parts of the imidazole compound containing the polymethyl methacrylate group are dissolved in 54 mass parts of butanone and toluene in a ratio of 1:1:1 , propylene glycol methyl ether mixed solvent, at 50°C, stir for 2 hours, after the two imidazole compounds are completely dissolved, then add 10 parts by mass of phenolic curing agent, 12 parts by mass of silicon dioxide, 12.5 parts by mass of Talc powder, 40 parts by mass of bisphenol-A epoxy resin, 0.5 parts by mass of 2-phenylimidazole, and continue to stir evenly to prepare a glue solution, impregnate the above glue solution with 7628 type E glass cloth, and heat it at 165 ° C Dry to remove the solvent to obtain a prepreg with a resin content of 45%. Stack 5 pieces of the prepregs obtained, arrange a release film with a thickness of 30 microns on the upper and lower sides, and place them in a vacuum press with programmable temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com