Dispersion layer composite damping material with vacant-shell foam ceramic balls as aggregate

A technology of composite damping material and foam ceramics, applied in ceramic products, applications, household appliances, etc., can solve the problems of difficulty in promoting large-scale protective structure design, strength mismatch, attenuation coefficient decline, etc., and achieve flexible and changeable construction methods. , Improve the comprehensive protection ability, the effect of high ground impact attenuation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

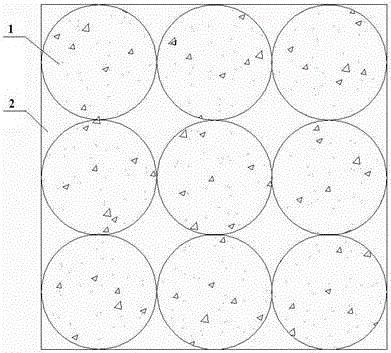

[0046] The novel dispersion layer material of the present invention is further described in detail with reference to the accompanying drawings and examples.

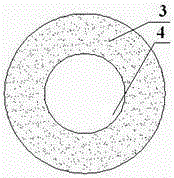

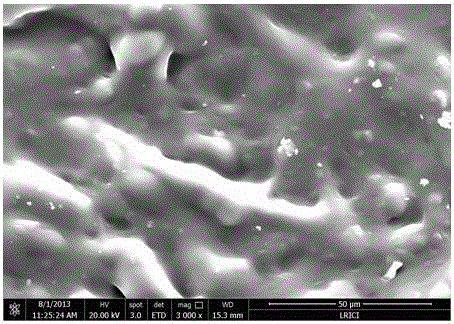

[0047] Such as Figure 1 to Figure 3c As shown, a dispersion layer composite damping material with empty shell ceramic foam balls as aggregate, including: empty shell foam ceramic balls 1, a mixture 2 of high-viscosity asphalt and polystyrene particles, and the hollow shell foam ceramic balls 1 is the most closely packed, formed by foam ceramic sintering process, such as figure 2 As shown, the outer diameter is 5cm, the inner diameter is 3cm, the foam pore diameter is 1mm, the porosity is 65%, and the ceramic foam density is 0.62g / cm 3 , the compressive strength is 6.05MPa~9.41MPa; the blend of high viscoelastic asphalt and polystyrene particles is filled in the gap, and the mass ratio of high viscoelastic asphalt and polystyrene particles is 100:2. The polystyrene particles have a diameter of 1 mm. The high viscoela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com