an oil pipeline

An oil transportation and pipeline technology, applied in the direction of pipeline protection, pipeline protection through thermal insulation, pipeline anti-corrosion/anti-rust protection, etc. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

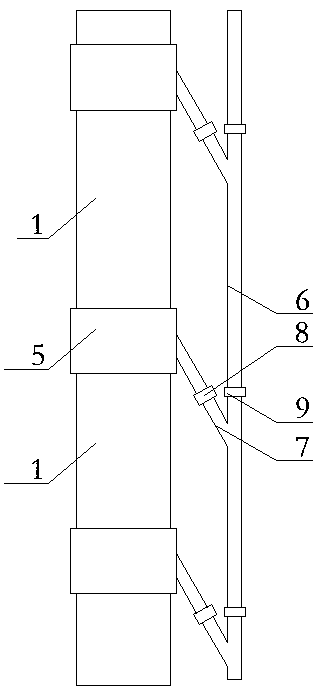

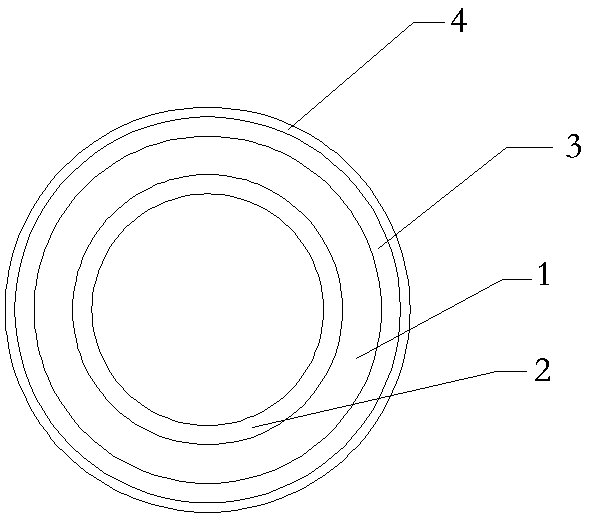

[0028] Such as figure 1 As shown, a petroleum transportation pipeline includes a pipe body 1, the inner wall of the pipe body 1 is provided with a layer of antistatic layer 2, the outer wall is provided with a layer of heat insulation layer 3, and the outer wall of the heat insulation layer 3 is provided with a layer of buffer layer 4 , a plurality of joints 5 are arranged on the pipe body 1, a dredging pipe 6 connected to the gas source is arranged in parallel outside the pipe body 1, and a purging pipe 7 communicating with the joint 5 is arranged on the dredging pipe 6. A purge valve 8 is provided, and the thickness of the heat insulating layer 3 is 1-3mm (the optimum thickness is 2mm, of course, 1mm or 3mm can also be selected), and it is composed of ceramic fibers, and the ceramic fibers evenly and seamlessly wrap the The pipe body 1, the buffer layer 4 has a thickness of 200-500 μm (the optimum thickness is 300 μm, of course 200 μm or 500 μm can also be selected), which i...

Embodiment 2

[0037] This embodiment is the same as Embodiment 1, except that the special antistatic coating is composed of the following raw materials in mass percentage: 13% epoxy-terminated polyurethane resin, 6% titanium dioxide, and 17% epoxy resin , conductive zinc oxide 13%, superfine aluminum silicate 6.5%, additives 4.4% and pigment 6.1%, the balance is water and unavoidable impurities; the pigment is composed of the following components by mass percentage: talcum powder 0.7% , 0.7% of mica powder, 1.8% of bentonite, 0.6% of nano-titanium dioxide-based composite particles, 2.3% of silicon-aluminum-based hollow microspheres, and the additives are composed of the following components by mass percentage: 0.6% diluent, 0.6% dispersant, 0.6% defoamer, 0.6% leveling agent, 2% curing agent, the dispersant is polyethylene wax, the defoamer is polyether modified silicone defoamer, and the diluent is epoxy active The diluent and the leveling agent are organo-modified siloxane, and the curing...

Embodiment 3

[0044] This embodiment is the same as Embodiment 1 and Embodiment 2, except that the special antistatic coating is composed of the following raw materials in mass percentage: 11% epoxy-terminated polyurethane resin, 5% titanium dioxide, and Oxygen resin 11%, conductive zinc oxide 10%, superfine aluminum silicate 5%, auxiliary agent 3% and pigment 5%, surplus is water and unavoidable impurity; Described pigment is made up of following components by mass percentage: 0.5% talc powder, 1% mica powder, 1.5% bentonite, 0.5% nano-titanium dioxide-based composite particles, 1.5% silicon-aluminum-based hollow microspheres, and the additives are composed of the following components by mass percentage: 0.5% diluent, 0.5% agent, 0.5% defoamer, 0.5% leveling agent, 1% curing agent, the dispersant is polyethylene wax, the defoamer is polyether modified silicone defoamer, the diluent It is an epoxy reactive diluent, the leveling agent is an organo-modified siloxane, and the curing agent is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com