Quantum dot/epoxy resin particle, preparation method thereof, quantum dot optical film and backlight module

A technology of epoxy resin and backlight module, which is applied in the direction of optics, nonlinear optics, electric light source, etc., can solve the problems of short service life of quantum dots, and achieve improved luminous efficiency, pure color, light conversion efficiency and brightening effect Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

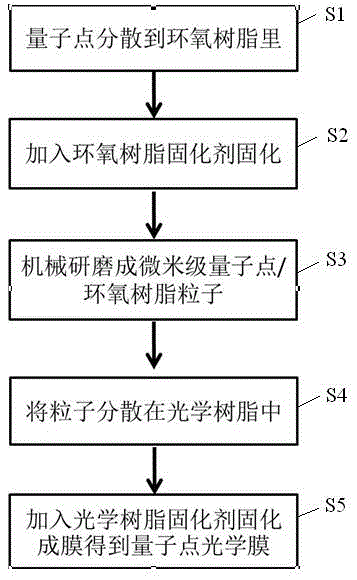

[0060] Preparation of quantum dots / epoxy particles:

[0061] 1) Disperse red and green quantum dots CdTe / CdS into hydrogenated bisphenol A epoxy resin diluted with butyl glycidyl ether, and further disperse and mix evenly by mechanical shearing. Wherein red and green quantum dots account for 1% and 5% of hydrogenated bisphenol A type epoxy resin respectively;

[0062] 2) Under stirring conditions, add the curing agent maleic anhydride and the methylimidazole with a mass proportion of 75% of the hydrogenated bisphenol A epoxy resin, and then slowly raise the temperature to 130-160°C to cure Obtain quantum dot / epoxy resin bulk material;

[0063] 3) The obtained quantum dot / epoxy resin block material is mechanically ground to obtain CdTe / CdS quantum dot / epoxy resin particles with a particle size of 3-5 μm and double bond groups on the surface.

[0064] Preparation of quantum dot optical film:

[0065] i) The prepared CdTe / CdS quantum dots / epoxy resin particles are dispersed in...

Embodiment 2

[0069] Preparation of quantum dots / epoxy particles:

[0070] 1) Disperse the red and green quantum dots CdSe / ZnS into the bisphenol S epoxy resin treated with phenyl glycidyl ether, and further mix them uniformly by ultrasonic dispersion. Among them, the red and green quantum dots accounted for 3% and 8% of the hydrogenated bisphenol A epoxy resin, respectively.

[0071] 2) Under the condition of stirring, add the curing agent isophorone diamine with a mass ratio of 2:1 to the bisphenol S epoxy resin, then slowly raise the temperature to 80°C, and cure to obtain the quantum dot / epoxy resin block material .

[0072] 3) The obtained quantum dot / epoxy resin bulk material is mechanically ground to obtain 2-3 μm CdSe / ZnS quantum dot / epoxy resin particles containing amine groups on the surface.

[0073] Preparation of quantum dot optical film:

[0074] i) Setting the water and oxygen barrier layer SiO on the side of the quantum dot layer 2 / parylene.

[0075] ii) Disperse the p...

Embodiment 3

[0079] Preparation of quantum dots / epoxy particles:

[0080] 1) Disperse red quantum dots CdTe / CdS / ZnS and green quantum dots CdSe / CdS into reactive diluent-treated bisphenol F epoxy resin, and further disperse and mix uniformly by mechanical shearing. Among them, the red and green quantum dots accounted for 2% and 6% of the hydrogenated bisphenol A epoxy resin, respectively.

[0081] 2) Under stirring conditions, add a curing agent ethylenediamine in a ratio of 3:1 to the bisphenol F epoxy resin substance, and cure at room temperature to obtain a quantum dot / epoxy resin block material;

[0082] 3) The obtained quantum dot / epoxy resin bulk material is mechanically ground to obtain 4-6 μm quantum dot / epoxy resin particles containing amine groups on the surface.

[0083] Preparation of quantum dot optical film:

[0084] i) The prepared quantum dots / epoxy resin particles are dispersed in the optical resin PU, and coated on the prepared transparent substrate PET, followed by hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com