Nano gold-mesoporous silica composite nanotube, preparation and applications thereof

A technology of mesoporous silica and nanotubes, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc. The particle growth becomes larger, easy to fall off and loss, etc., to achieve the effect of not reducing the catalytic performance, large specific surface area, and simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

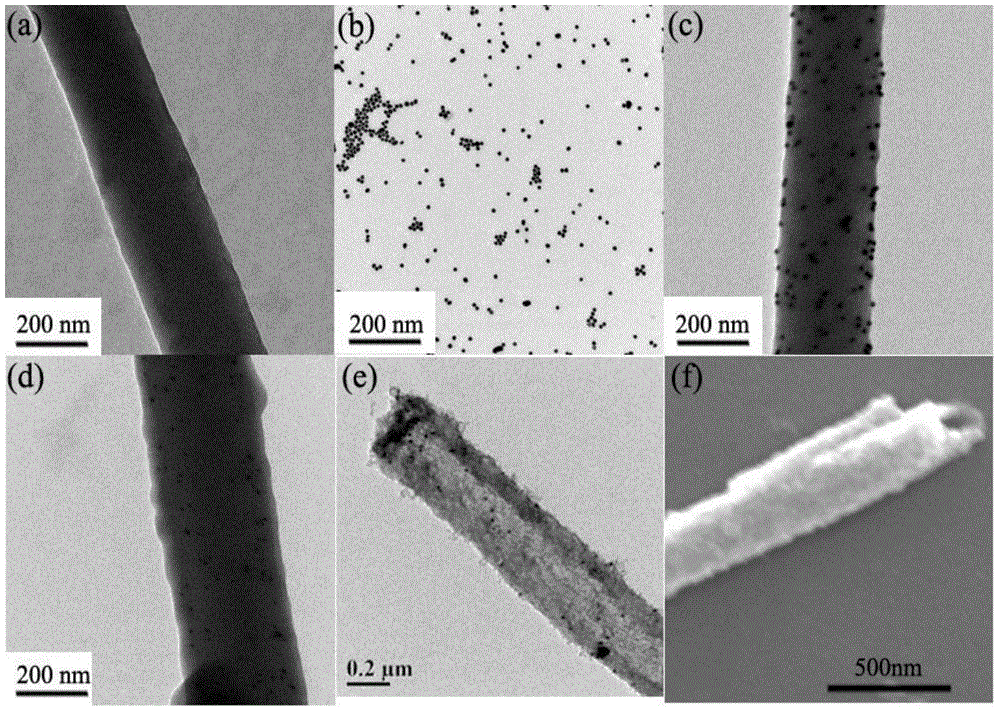

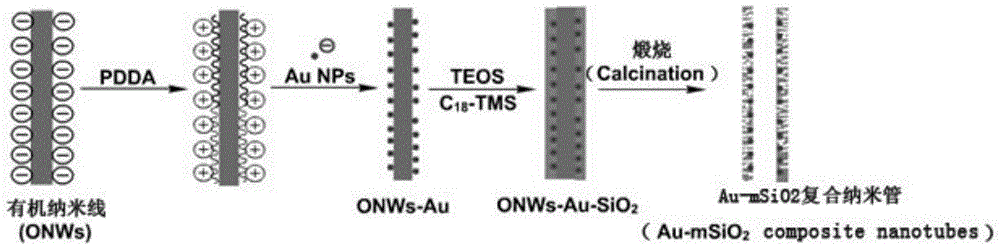

[0034] The first step: Adsorption modified aniline oligomer organic nanowires with PDDA. Disperse 0.1 g of aniline oligomer organic nanowires in 20 g of water, add 0.5 g of an aqueous solution of PDDA with a mass concentration of 20-35 wt %, and stir and adsorb at room temperature for 10 min. After centrifugation and washing with water, the modified organic nanowires were redispersed in 20 g of water for use (concentration of 0.5 wt% to 1 wt%), and the surface potential was +60 mV.

[0035] The second step: synthesis of AuNPs. Prepare a concentration of 5.0×10 in a three-necked flask -4 150 mL of chloroauric acid solution of M was heated to boiling with magnetic stirring, and then poured into 7.5 mL of 1 wt % sodium citrate solution. After reacting for 30 min, a purple-red AuNPs dispersion (concentration: 6 g / L) was obtained, which was cooled to room temperature for use.

[0036] The third step: AuNPs were adsorbed onto the surface of PDDA-modified organic nanowires. 1 mL ...

Embodiment 2-4

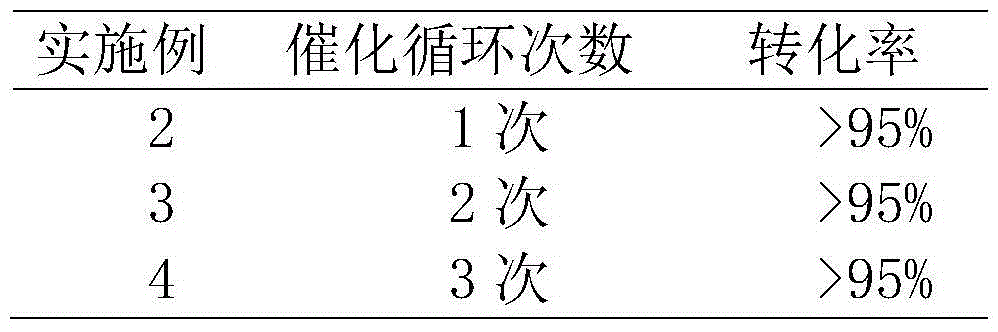

[0043] Test Au-mSiO 2 The catalytic performance of the composite nanotubes on the degradation of p-nitrophenol did not decrease at all after being recycled for 3 times. According to Table 1, other preparation, reaction and test conditions were the same as in Example 1.

[0044] Table 1

[0045]

Embodiment 5-9

[0047] The size and loading capacity of the nano-gold catalyst can be easily and effectively regulated, which can be adjusted by changing the amount of the added AuNPs dispersion. As described in Table 2, other preparation, reaction and test conditions are the same as in Example 1.

[0048] Table 2

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com