Flexible lithium ion battery cathode and manufacturing method thereof

A lithium-ion battery and a manufacturing method technology, applied in the field of designing lithium-ion batteries, can solve the problems of battery heating failure, thermal runaway explosion, slow lithium insertion kinetics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

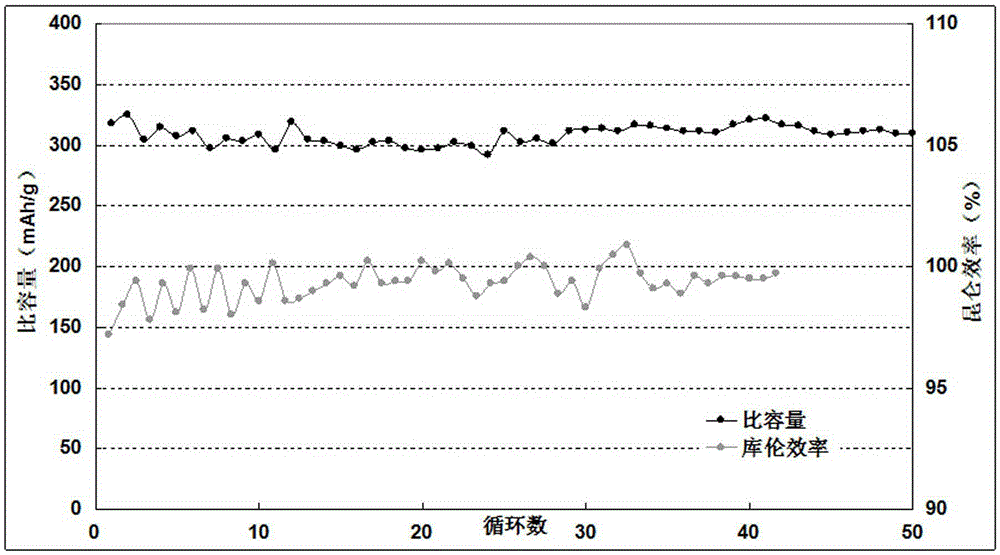

Embodiment example 1

[0067] Add one part of superP conductive agent by mass to 15 parts by mass of low-boiling point solvent absolute ethanol, disperse with a planetary mixer at a high speed of 2000rpm for 30 minutes to form a uniform conductive paste, and then add 8.4 parts by mass of lithium-ion battery negative electrode active Material artificial graphite, continue to stir at the same stirring speed for 60 minutes to obtain the slurry containing active material and conductive agent, and then add a part of PTFE emulsion with a solid content of 60% by mass, so that the active material: conductive agent: solid of ptfe The mass ratio is 84%: 10%: 6%. Perform high-speed dispersion again for 10 minutes and then turn on the heating function of the mixer to raise the temperature of the slurry to 60°C and stir for 60 minutes before use;

[0068] Pour the prepared slurry into a flat heating plate, place it in a vacuum drying oven, slowly evacuate to -0.1MPa and heat to 80°C to completely volatilize the a...

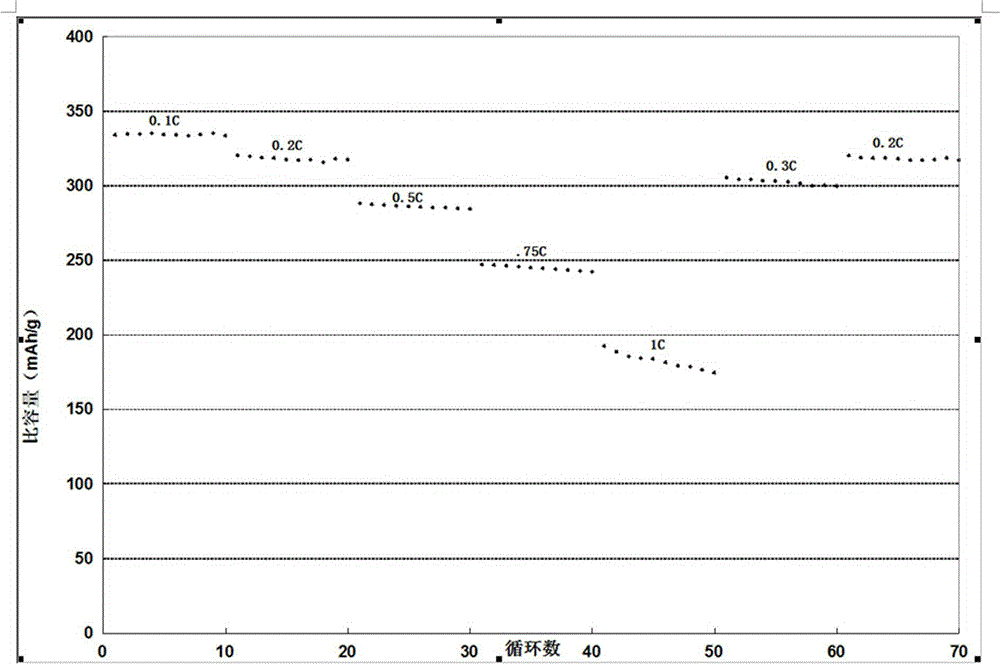

Embodiment example 2

[0072] Add a mass of superP conductive agent to 15 mass parts of deionized water containing 50% absolute ethanol, use a planetary mixer to disperse at a high speed of 2500rpm for 30 minutes to form a uniform conductive paste, then add 8.4 mass parts of lithium-ion batteries Use the negative electrode active material mesophase carbon microsphere MCMB, continue to stir at the same stirring speed for 60 minutes, and then add a PTFE emulsion with a solid content of 60% by mass to make the active material : Conductive agent: The solid mass ratio of ptfe is 84%: 10%: 6%. Perform high-speed dispersion again for 10 minutes and then turn on the heating function of the mixer to raise the temperature of the slurry to 60°C and stir for 60 minutes before use;

[0073] Pour the prepared slurry into a flat heating plate, place it in a vacuum drying oven, slowly evacuate to -0.1MPa and heat to 110°C to completely volatilize the absolute ethanol aqueous solution in the slurry to obtain a dry po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com