Paper defect detection method based on bit planes

A technology of paper defect detection and bit plane, applied in the field of paper defect detection, can solve the problems of complex fuzzy logic algorithm recognition and subsequent processing, great influence on detection results, one-dimensional autoregressive algorithm cannot be used for texture modeling and defect detection, etc. , to achieve the effect of simple and easy implementation, large market potential, and simple and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

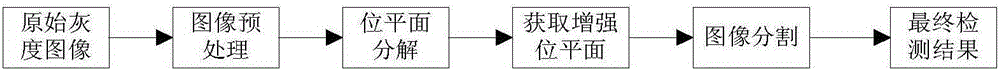

[0030] In the present invention, the image containing paper defects is used as the detected object, and the processing flow is as follows: figure 1 As shown, the specific implementation steps are as follows:

[0031] Step1. Obtain the original image of the tested paper through the CCD camera and convert it into a grayscale image.

[0032] Step2. Perform adaptive median filter processing on the obtained grayscale image to eliminate noise in the image. It can adaptively adjust the size of the filter window and output the filter result according to the degree of interference of the image by noise. The initial filter radius is selected as 3. The maximum filter radius is 10. The specific method is to use the filter window to perform sliding scanning from the upper left corner of the original image to judge whether there are noise points. The basis for judging is whether ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com