A kind of lubricating thread locking and sealing anaerobic adhesive and preparation method thereof

An anaerobic glue and thread technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problem of unfavorable coloring of glue, cannot improve the lubricity and curing performance of anaerobic glue for thread locking and sealing, and affect thread locking. Sealing anaerobic adhesive torque strength and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The embodiment of the present invention also provides a preparation method of a lubricated thread locking and sealing anaerobic adhesive, comprising the following steps:

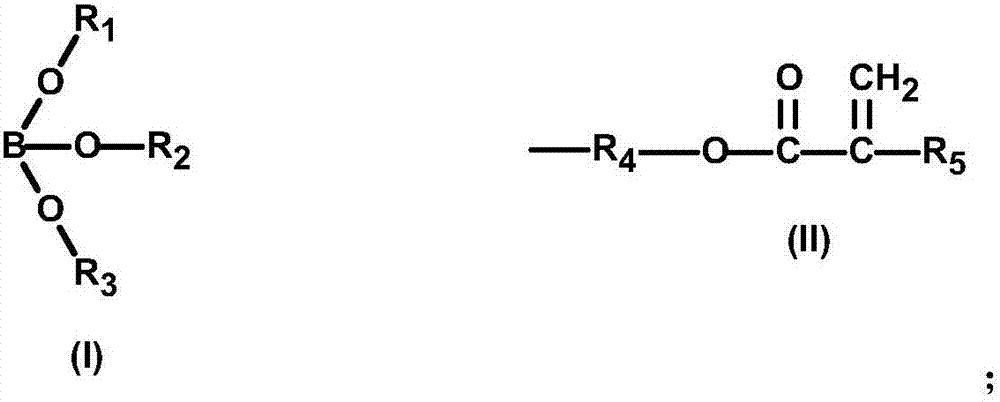

[0066] Prepare the self-lubricating monomer first: the reaction vessel is connected in series with a water separator, a condenser, and a vacuum system; according to the different structural formulas of the self-lubricating monomer to be prepared, two methods can be used to prepare the self-lubricating monomer:

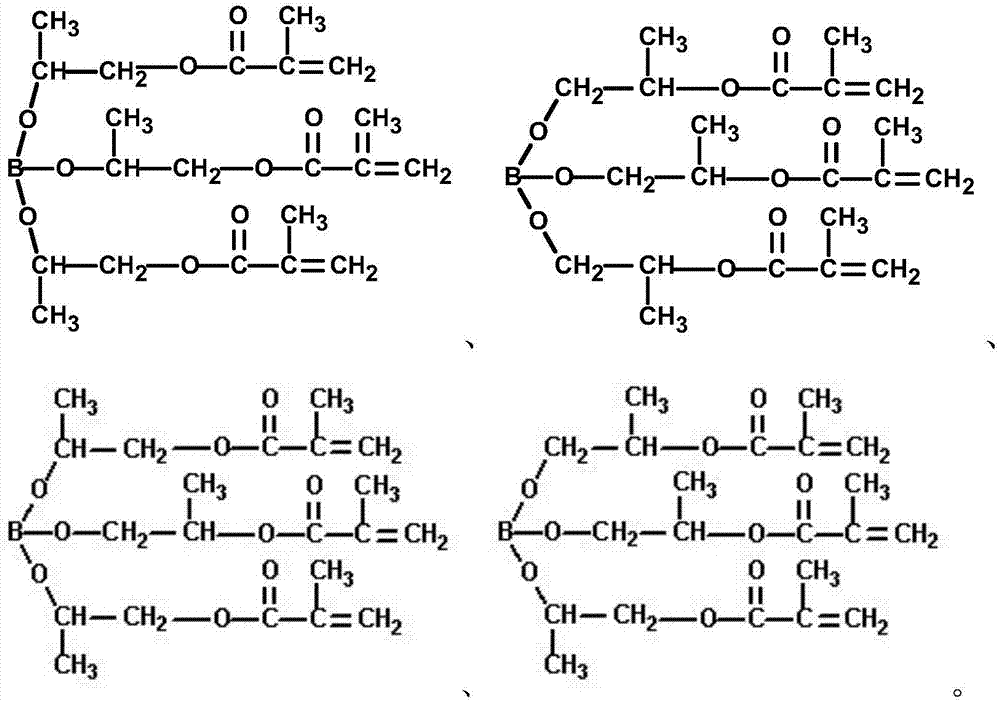

[0067] Method 1: Prepare basic raw materials: boric acid and hydroxyacrylate, wherein the molar ratio of boric acid to hydroxyacrylate is 1:3; put in boric acid and hydroxyacrylate, and then add a total amount of 0.05% to 0.5% Wt polymerization inhibitor, Stir and heat up and keep warm at 80°C to 130°C for esterification reaction, vacuumize to remove water, water vapor flows back to the water separator after passing through the condenser, collect distillate water and weigh it, when the quality ...

Embodiment 1

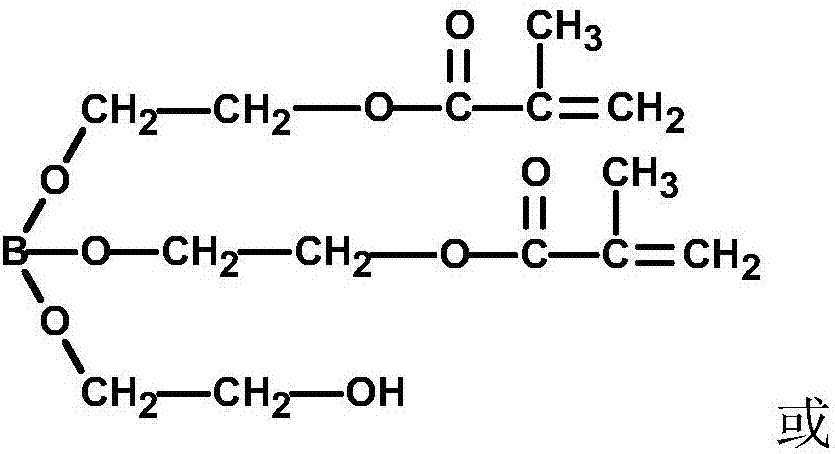

[0079] The lubricating type thread lock sealing anaerobic adhesive provided in this embodiment includes 20% self-lubricating monomer, 20% methacrylic epoxy resin, 50% polyethylene glycol 200 dimethacrylate, 6 % of pentaerythritol tetramethacrylate, 0.04% of 1,4-naphthoquinone (inhibitor), 0.34 of N-acetylphenylhydrazine (promoter), 2% of o-sulfonyl benzimide (promoter agent), 0.02% EDTA tetrasodium salt (metal ion chelating agent), 1.6% cumene hydroperoxide (organic peroxide initiator). Among them, the structural formula of the self-lubricating monomer is:

[0080]

[0081] The preparation process of the above lubricated thread locking and sealing anaerobic adhesive is as follows:

[0082] Preparation of self-lubricating monomer: the reaction vessel is connected in series with water separator, condenser, and vacuum system, and the basic raw materials are prepared: boric acid, hydroxyethyl methacrylate; boric acid and hydroxyethyl methacrylate are put in at a molar ratio of...

Embodiment 2

[0085] The lubricated thread lock seal anaerobic adhesive provided in this embodiment includes 30.00% self-lubricating monomer, 20.64% methacrylic epoxy resin, 45.50% triethylene glycol dimethacrylate, 0.04% of 1,4-naphthoquinone (inhibitor), 0.30 of N-acetylphenylhydrazine (accelerator), 1.50% of o-sulfonyl benzimide (co-accelerator), 0.50% of butene Diacid (promoter), 0.02% EDTA tetrasodium salt (metal ion chelating agent), 1.5% cumene hydroperoxide (organic peroxide initiator). Wherein, the self-lubricating monomer has the same structural formula as the self-lubricating monomer in Example 1.

[0086] The preparation process of the above lubricated thread locking and sealing anaerobic adhesive is as follows:

[0087] Preparation of self-lubricating monomer: the reaction vessel is connected in series with water separator, condenser, and vacuum system, and the basic raw materials are prepared: boric acid, hydroxyethyl methacrylate; boric acid and hydroxyethyl methacrylate are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com