Nickel waste water treatment method for chip production line

A treatment method and production line technology, applied in heating water/sewage treatment and other directions, can solve problems such as affecting the economic benefits of chip processing enterprises, unfavorable chip sustainable development, complex treatment steps, etc., to promote sustainable development and equipment maintenance costs. Low, high throughput effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

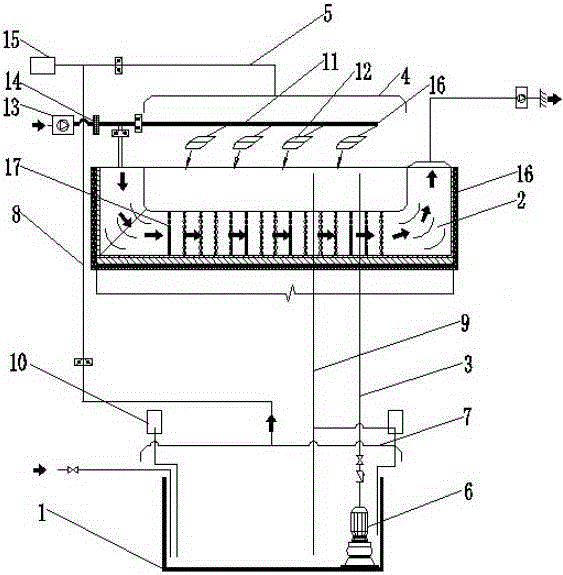

[0030] A method for treating nickel waste water in a chip production line, comprising waste water collection, waste water evaporation, waste gas treatment and solid waste residue treatment; the waste water evaporation is to enter high-temperature gas into the evaporation chamber 2 for heating and evaporation, the evaporation time is 12 hours, and the evaporation temperature is 220°C.

[0031] The waste gas in the waste gas treatment step in this embodiment is treated with a BFT acid mist purification tower. The BFT acid mist purification tower is a treatment tower with a packing type gas-liquid mass transfer circular structure. The packing layer is: two to five layers Polypropylene multifaceted hollow balls with a diameter of 50mm and toothed packing, the treatment process is to draw the exhaust gas into the tower through the fan, and wash it with sodium hydroxide with a concentration of 5-10%. After the washing liquid is purified by the purification tower, To meet the dischar...

Embodiment 2

[0034] A method for treating nickel waste water in a chip production line, comprising waste water collection, waste water evaporation, waste gas treatment and solid waste residue treatment; the waste water evaporation is to enter high-temperature gas into the evaporation chamber 2 for heating and evaporation, the evaporation time is 16 hours, and the evaporation temperature is 180°C, the container of the evaporation chamber in this embodiment is made of stainless steel, and the specification is 100cm*200cm*100cm.

[0035] The high-temperature gas in this embodiment is the high-temperature exhaust gas generated in the chip production workshop, and the specific source is: exhaust gas generated in processes such as wafer diffusion, wafer oxidation, chip chemical vapor deposition, and chip passivation.

[0036] The flow rate of the high-temperature gas in this embodiment is 200 L / min.

[0037] The wastewater collection in this embodiment refers to collecting nickel wastewater from...

Embodiment 3

[0040] A method for treating nickel waste water in a chip production line, comprising waste water collection, waste water evaporation, waste gas treatment and solid waste residue treatment; the waste water evaporation is to enter high-temperature gas into the evaporation chamber 2 for heating and evaporation, the evaporation time is 14 hours, and the evaporation temperature is 200°C.

[0041] The high-temperature gas in this embodiment is the high-temperature waste gas generated in the chip production workshop.

[0042] The flow rate of the high-temperature gas in this embodiment is 300 L / min.

[0043]The wastewater collection in this embodiment refers to collecting nickel wastewater from the production line into the wastewater collection pool 1, and the wastewater collection pool 1 transports the wastewater to the evaporation chamber 2 through the wastewater supply pipeline 3; specifically, the evaporation chamber 2 is located in the waste water Above the collection pool 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com