A high-temperature far-infrared radiation heating plate and its manufacturing method

A manufacturing method and far-infrared technology are applied in the production and processing of thermal insulation materials and electric heating elements, and in the field of electric heating element production. Good, fast heating, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below by embodiment, and these embodiments are only used to illustrate the present invention, do not limit the scope of the present invention:

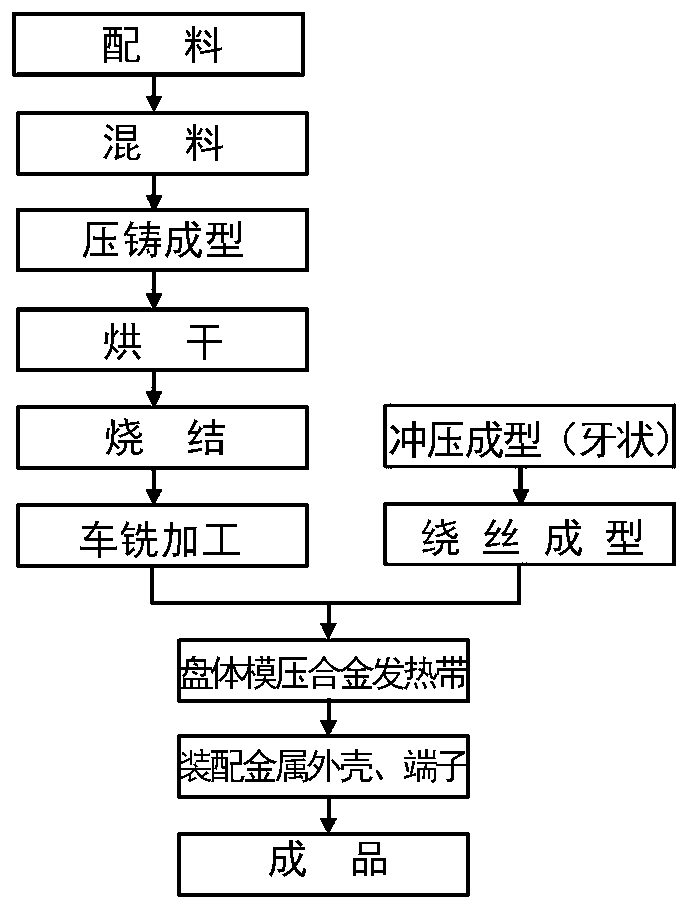

[0019] Take 80-89% of high-alumina ceramic fiber cotton, 3-8% of silica sol, and 8-12% of modified starch. After mixing, add 50% of water to form a viscous muddy mixture, and die-cast the mixture at room temperature Molding, drying the die-casted product in an environment of 350-400°C, sintering the dried product in an environment of 750-800°C for 15 minutes to solidify and harden to form a blank, and turning and milling the blank to form a thermal insulation The heat-insulating disk body, the alloy heating tape raw material is stamped into a "tooth" shape, the "tooth"-shaped alloy heating tape is coiled and formed according to the corresponding shape mold, and then mechanically molded on the heat-insulating and heat-insulating disk body, and finally the terminal connection de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com