Thin coating type thermal insulation coating and preparation method thereof

A technology of thermal insulation coating and thin coating, applied in the field of coatings, can solve the problems of poor wetting ability between hollow glass microspheres and water, poor adhesion of the base layer, difficulty in dispersion, etc., to reduce VOC indicators, good heat insulation effect, base material The effect of using less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

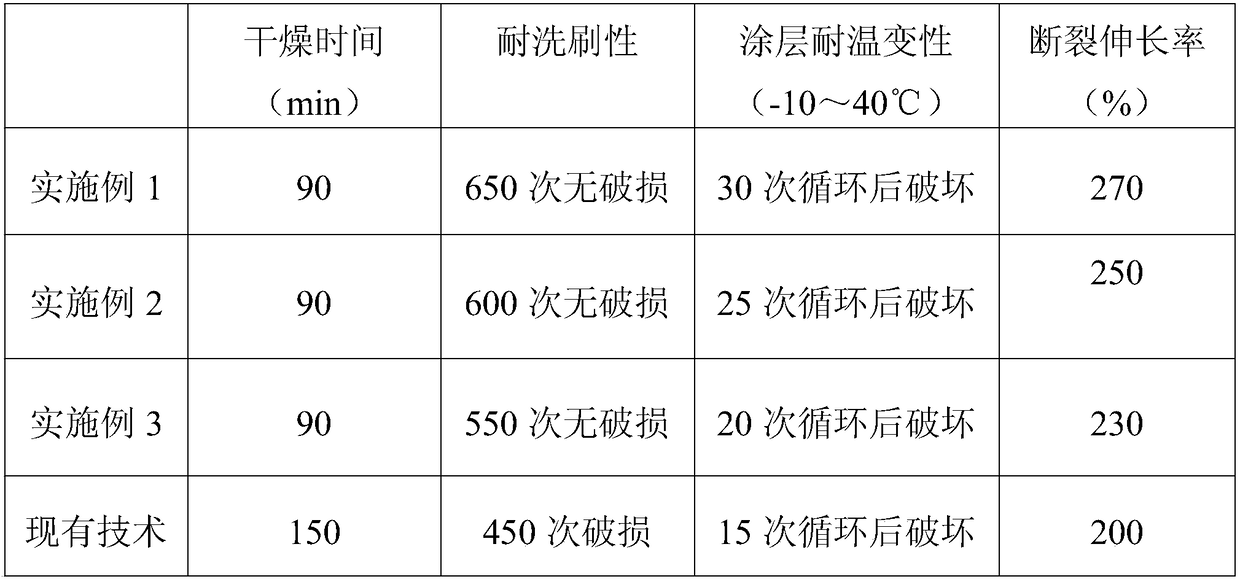

Examples

Embodiment 1

[0021] A thin coating type thermal insulation coating, comprising the following components in weight percentage: 25% of hollow glass microsphere powder, 4% of nanoscale whisker powder, 10% of polyacrylic resin emulsion glue, ethylene glycol monobutyl ether film-forming aid 2%, acrylate thickener 2%, sigma-A8311 defoamer 4%, acrylate carboxylate dispersant 2%, natural pigment 3%, rutile titanium dioxide 10%, and the balance is deionized water; , the hollow glass microsphere powder includes three specifications of hollow glass microsphere powder produced by Shanxi Hainuo Technology Co., Ltd.:

[0022] HN20, HN40 and HN60, the weight percentages of the three hollow glass microsphere powders are: HN2030%, HN4040% and HN6030%; the nanoscale whisker powder is selected from DK-Si- 001 (main component is Si, purity 99.9%, spherical shape, average particle size 35nm).

[0023] The preparation method of the above-mentioned thin-coated thermal insulation coating is: adding hollow glass ...

Embodiment 2

[0025] A thin coating type thermal insulation coating, comprising the following components by weight percentage: 30% of hollow glass microsphere powder, 2% of nanoscale whisker powder, 20% of polyacrylic resin emulsion glue, ethylene glycol monobutyl ether film-forming aid 1%, acrylate thickener 4%, sigma-A8311 defoamer 2%, acrylate carboxylate dispersant 4%, natural pigment 1%, rutile titanium dioxide 15%, and the balance is deionized water; , the hollow glass microsphere powder is a functional hollow glass microsphere powder, produced by Jinan Great New Material Co., Ltd., the model is ND1.93; the nanoscale whisker powder is selected from Beijing Deke Daojin Technology Co., Ltd. The produced DK-Si-001 (main component is Si, purity 99.9%, spherical shape, average particle size 35nm).

[0026] The preparation method of the above-mentioned thin-coated thermal insulation coating is: adding hollow glass microsphere powder, nano-scale whisker powder, polyacrylic resin emulsion glu...

Embodiment 3

[0028] A thin coating type thermal insulation coating, comprising the following components in weight percentage: 25% of hollow glass microsphere powder, 3% of nanoscale whisker powder, 15% of polyacrylic resin emulsion glue, ethylene glycol monobutyl ether film-forming aid 1.5%, 3% acrylate thickener, 3% sigma-A8311 defoamer, 3% acrylate carboxylate dispersant, 3% natural pigment, 13% rutile titanium dioxide, and the balance is deionized water; , the hollow glass microsphere powder is a functional hollow glass microsphere powder, produced by Jinan Great New Material Co., Ltd., the model is ND 1.93; the nanoscale whisker powder is produced by Beijing Deke Daojin Technology Co., Ltd. DK-Si-001 (main component is Si, purity 99.9%, spherical shape, average particle size 35nm).

[0029] The preparation method of the above-mentioned thin-coated thermal insulation coating is: adding hollow glass microsphere powder, nano-scale whisker powder, polyacrylic resin emulsion glue, ethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com