Device for testing fire resistance of fireproof plugging material and use method thereof

A fire-resistant performance and fire-proof sealing technology, which is applied in the field of devices for testing the fire-resistant performance of fire-proof sealing materials, can solve the problems of inability to observe in real time, obtain the quality and changes of fire-proof materials, and achieve simple structure, low cost, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described below with reference to the accompanying drawings.

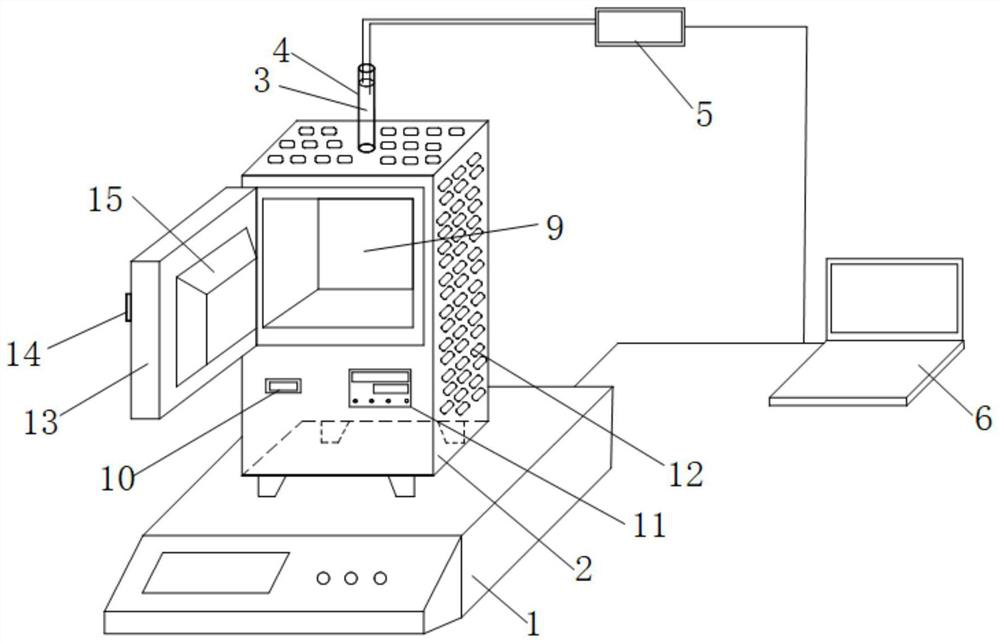

[0029] Please refer to figure 1 , the embodiment of the present invention provides a device for testing the fire resistance of a fire blocking material and a method for using the same.

[0030] The refractory test furnace body 2 is placed on the weighing member 1. In this embodiment, the weighing member 1 is an electronic scale, and its load-bearing accuracy is higher than or equal to 0.01g. The weighing member 1 is used for The change in mass over time was measured throughout the experiment.

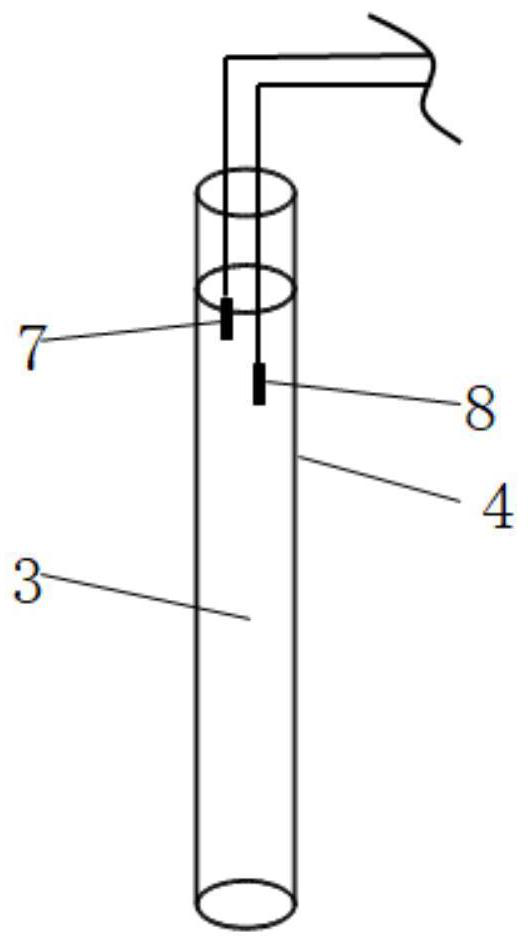

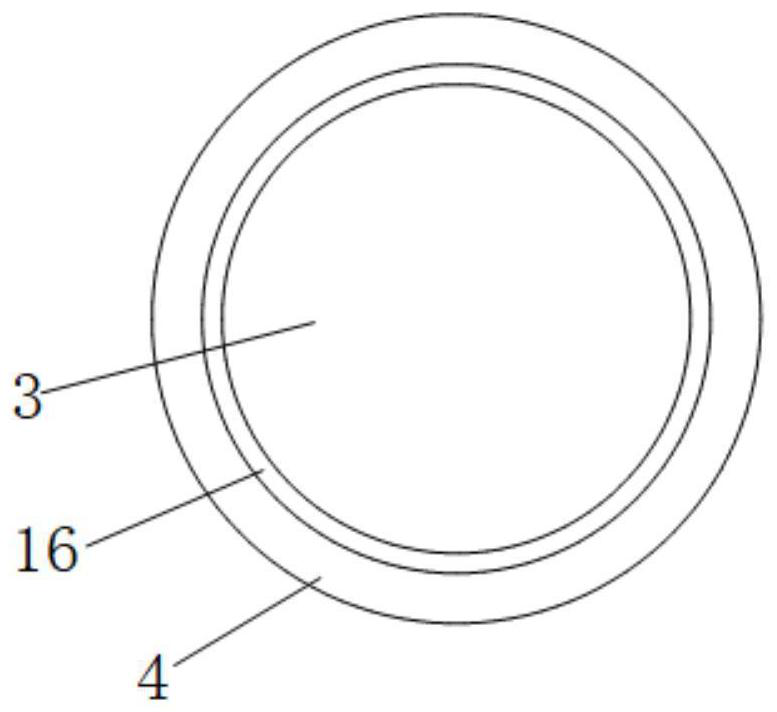

[0031] The upper part of the refractory test furnace body 2 is a furnace chamber 9, and the lower part is provided with a power switch 10 and a temperature control instrument 11, wherein the furnace chamber 9 is used to provide a high temperature environment fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com