Method for chemically plating copper on surface of expanded graphite

A technology of expanded graphite and surface chemistry, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve problems such as rising production costs, and achieve the effect of reducing usage and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

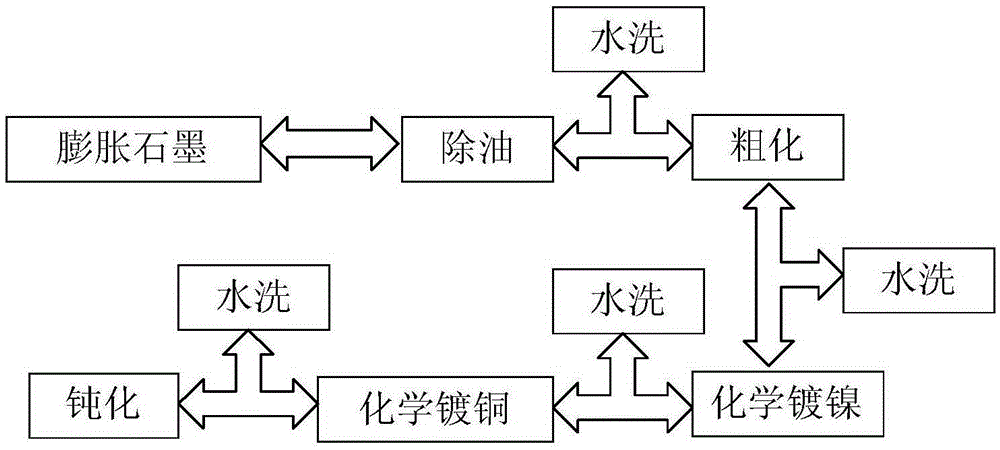

Method used

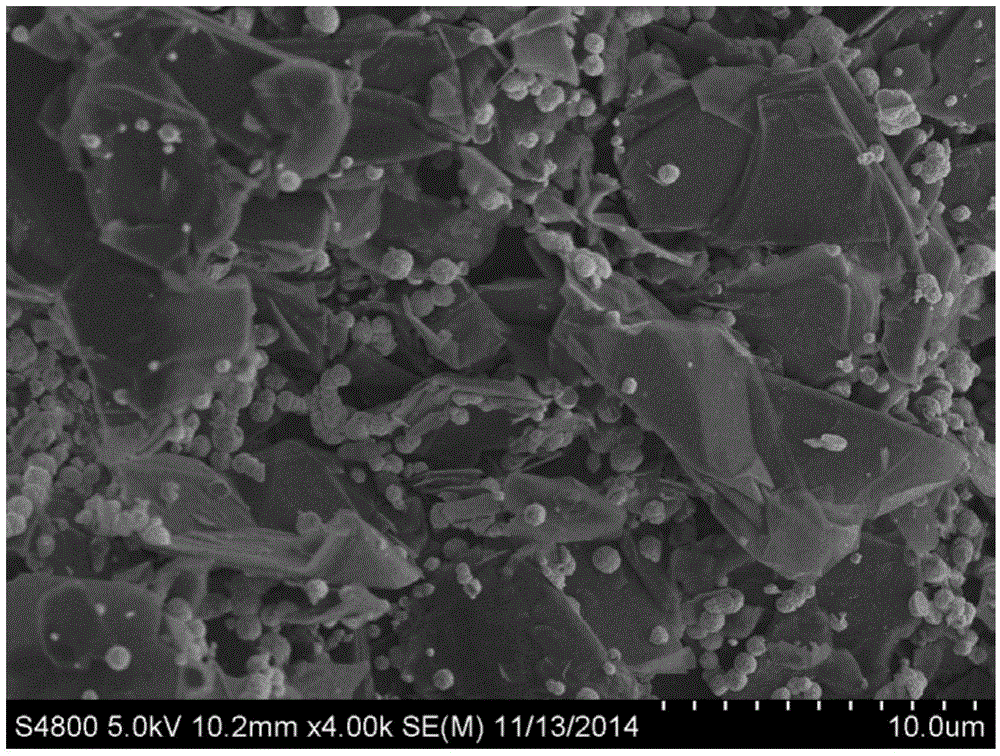

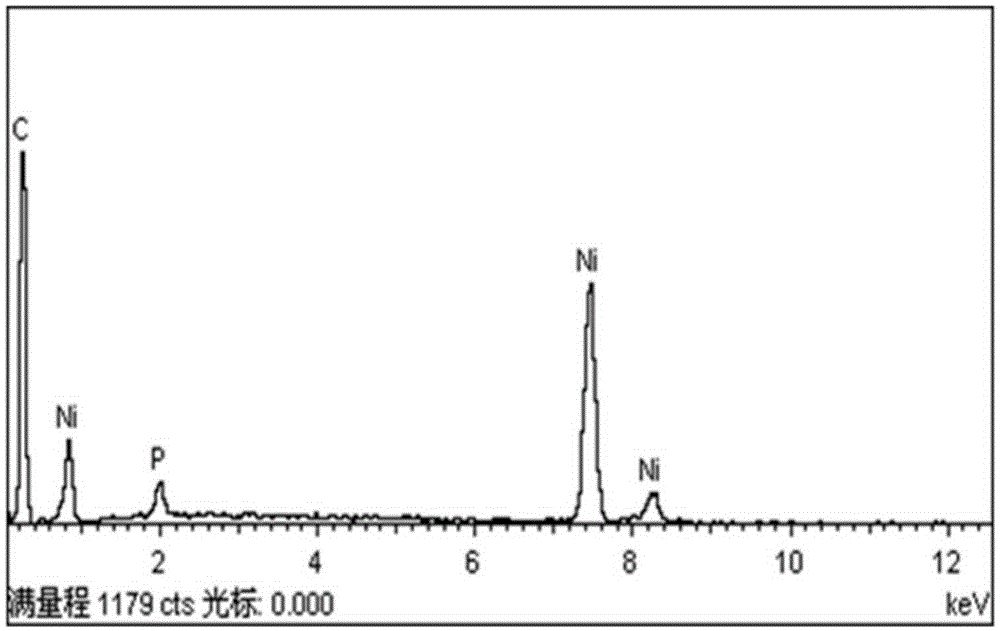

Image

Examples

Embodiment 1

[0030] Step 1: Preprocessing

[0031] 1.1 Surface degreasing: Weigh 3g of expanded graphite powder and place it in 100ml of NaOH alkaline solution with a mass fraction of 10%, stir magnetically at 70°C for 30min, wash it repeatedly with deionized water until neutral, and place it at 80°C Dry to constant weight before use.

[0032] 1.2 Coarsening treatment: Put the degreased expanded graphite powder in 200ml roughening solution, and stir it electromagnetically at 30°C for 30min. The composition of the coarsening solution is: 200g / L (NH 4 ) 2 S 2 o 8 (ammonium persulfate), 100ml / LH 2 SO 4 , H 2 SO 4 The density is 1.84g / cm 3 ; After coarsening, wash with deionized water to neutrality, dry to constant weight at 80°C before use;

[0033] Step 2: Electroless Nickel Plating

[0034] 2.1 Configure the electroless nickel plating solution: the electroless plating solution is composed of nickel sulfate hexahydrate, sodium citrate, ammonium chloride, sodium hypophosphite, ammo...

Embodiment 2

[0043] Step 1: Preprocessing

[0044] 1.1 Surface degreasing: Weigh 3g of expanded graphite powder and place it in 100ml of NaOH alkaline solution with a mass fraction of 10%, stir magnetically at 30°C for 50min, wash it repeatedly with deionized water until neutral, and place it at 90°C Dry to constant weight before use.

[0045] 1.2 Coarsening treatment: Put the degreased expanded graphite powder in 200ml of roughening solution, and stir it electromagnetically at 40°C for 15 minutes. The composition of the coarsening solution is: 150g / L (NH 4 ) 2 S 2 o 8 (ammonium persulfate), 100ml / LH 2 SO 4 , H 2 SO 4 The density is 1.84g / cm 3 ; After coarsening, wash with deionized water to neutrality, dry at 90°C to constant weight before use;

[0046] Step 2: Electroless Nickel Plating

[0047] 2.1 Configure the electroless nickel plating solution: the electroless plating solution is composed of nickel sulfate hexahydrate, sodium citrate, ammonium chloride, sodium hypophosphi...

Embodiment 3

[0056] Step 1: Preprocessing

[0057] 1.1 Surface degreasing: Weigh 2g of expanded graphite powder and place it in 100ml of NaOH alkaline solution with a mass fraction of 10%, stir it magnetically at 100°C for 20min, wash it repeatedly with deionized water until neutral, and place it at 100°C Dry to constant weight before use.

[0058] 1.2 Coarsening treatment: Put the degreased expanded graphite powder in 200ml of roughening solution, and stir it electromagnetically at 40°C for 5 minutes. The composition of the coarsening solution is: 175g / L (NH 4 ) 2 S 2 o 8 (ammonium persulfate), 75ml / LH 2 SO 4 , H 2 SO 4 The density is 1.84g / cm 3 ; After coarsening, wash with deionized water to neutrality, and dry to constant weight at 100°C before use;

[0059] Step 2: Electroless Nickel Plating

[0060] 2.1 Configure the electroless nickel plating solution: the electroless plating solution is composed of nickel sulfate hexahydrate, sodium citrate, ammonium chloride, sodium hyp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com