Ultralow-chroma PEHA for TPU and preparation method thereof

A chromaticity, ultra-low technology, applied in the field of PEHA, can solve problems such as yellowing, synthetic TPU and PEHA's insufficient temperature resistance, and achieve the effects of preventing oxidative yellowing, shortening production time, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The invention provides an ultra-low chroma PEHA for TPU. The raw materials of the PEHA include adipic acid, 1,6-hexanediol, ethylene glycol, a high-temperature antioxidant and a catalyst. The raw materials are:

[0040] Adipic acid 50~70%;

[0041] 1,6-hexanediol 10~25%;

[0042] Ethylene glycol 25~45%;

[0043] High temperature antioxidant 0.3~0.5%;

[0044] Catalyst 0.01~0.1%;

[0045] The high temperature antioxidant is phosphite;

[0046] The catalyst is stannous octoate.

[0047] The present invention also provides a preparation method of the ultra-low chroma PEHA, comprising the following steps:

[0048] (1) Add all adipic acid, ethylene glycol and high-temperature antioxidants into the reactor at the same time and stir to raise the temperature to form a mixture. At this time, it is necessary to check whether the cooling water is closed, and at the same time open the pipeline of the motor, partial condenser and total condenser of cooling water.

[0049] (2)...

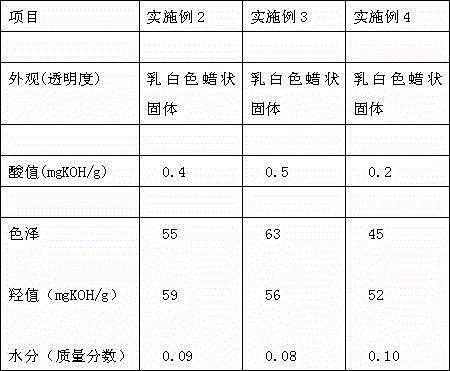

Embodiment 2

[0057] A preparation method of the ultra-low chroma PEHA, comprising the following steps:

[0058] (1) Add 2800kg of adipic acid, 2000kg of ethylene glycol and 30kg of high-temperature antioxidant into the reactor at the same time and stir to raise the temperature to form a mixture. At this time, it is necessary to check whether the cooling water is closed, and at the same time open the motor, partial condenser and total condenser tube road cooling water.

[0059] (2) Turn off the heat medium when the temperature in the tank rises to 90°C, and stir for 1 hour.

[0060] (3) After stirring for 1 hour, start to heat up. When the mixture starts to produce water, the temperature of the partial condenser is kept at 100°C, and the cooling water of the total condenser is half-opened. At the same time, the water weight of the receiver is weighed to 200kg.

[0061] (4) When the temperature rises to 220°C, measure AV after 1 hour at this temperature. When AV<30, add 8kg of catalyst and ...

Embodiment 3

[0066] A preparation method of the ultra-low chroma PEHA, comprising the following steps:

[0067] (1) Add 2500kg of adipic acid, 2000kg of ethylene glycol and 25kg of high-temperature antioxidant into the reactor at the same time and stir to raise the temperature to form a mixture. At this time, it is necessary to check whether the cooling water is closed, and at the same time open the motor, partial condenser and total condenser tube road cooling water.

[0068] (2) When the temperature in the tank rises to 95°C, turn off the heat medium and stir for 1 hour.

[0069] (3) After stirring for 1 hour, start to heat up. When the mixture starts to produce water, the temperature of the partial condenser is kept at 105°C, the cooling water of the total condenser is half-opened, and the water weight of the receiver is weighed at the same time to 220kg.

[0070] (4) When the temperature rises to 220°C, measure AV after 1 hour at this temperature. When AV<30, add 9kg of catalyst and 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com