Acetic acid and water separation method in aromatic carboxylic acid production

A separation method and technology of aromatic carboxylic acid, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., to achieve the effect of reducing energy, saving energy and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

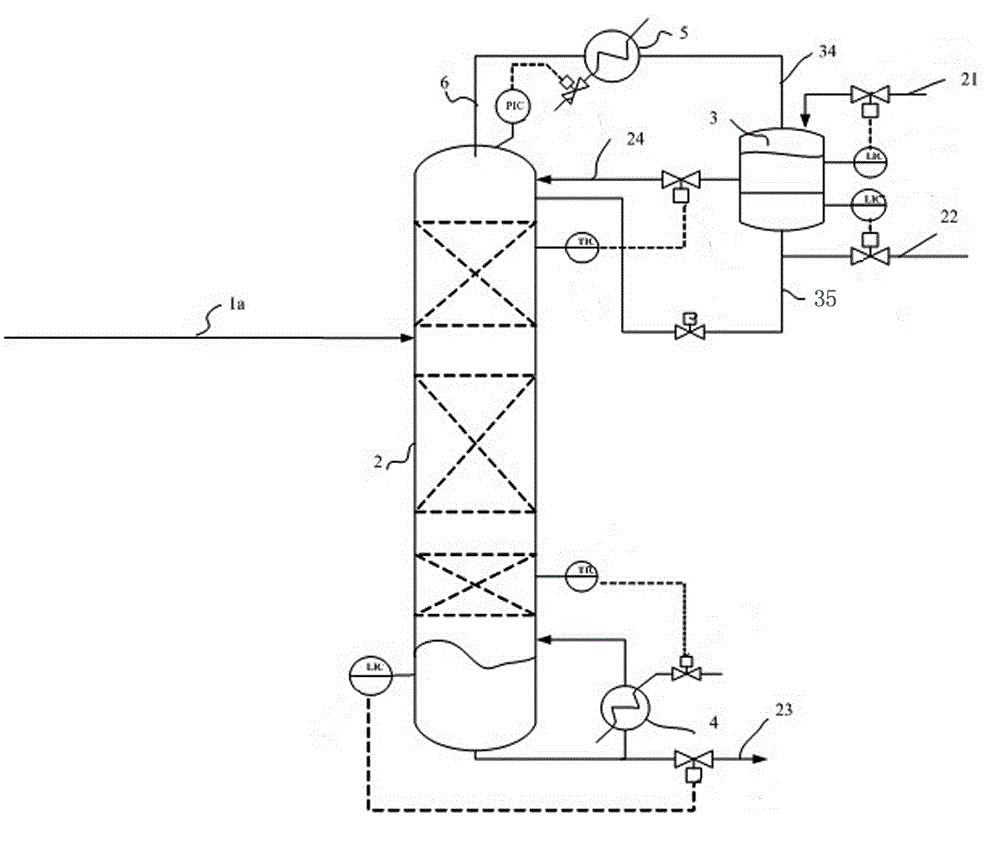

[0045] use figure 1 The traditional azeotropic distillation process separates acetic acid and water, wherein the entrainer is sec-butyl acetate. The stream 1a that needs to be separated by acetic acid and water is composed of stream 1, stream 3 and stream 4, which come from different units of the terephthalic acid system respectively, wherein stream 1, stream 3 and stream 4 and Its process parameters are shown in Table 1 below. According to the different material states and water concentrations of each stream, the respective feeding positions in the traditional azeotropic distillation column are shown in Table 1. Wherein the dilute acetic acid stream 1 enters the azeotropic rectification column at the position of the tray 9 . At the top of the azeotropic rectification tower 2, the replenishment of the entrainer sec-butyl acetate is carried out by the stream 21, and the steam stream 6 flowing out from the top of the tower enters the condenser 5 to be condensed into a liquid ...

Embodiment 2

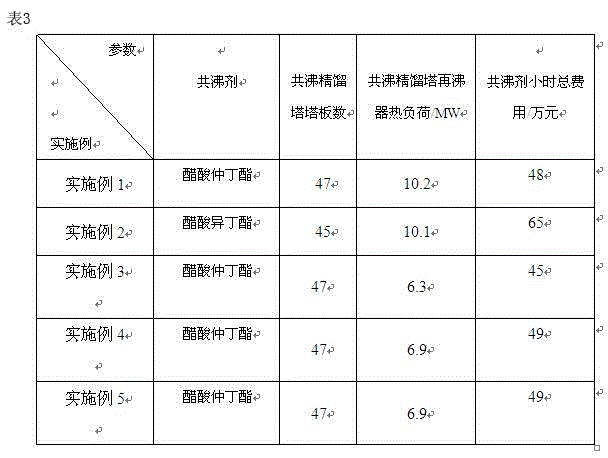

[0048] The entrainer that adopts is changed into isobutyl acetate, wherein stream 1, stream 3, stream 4 and process parameters thereof are as shown in Table 2 below, and other implementation processes are with embodiment 1. The stream 35 refluxed to the top of the azeotropic distillation column contains acetic acid with a concentration≦0.05wt%. The mass concentration of the acetic acid solvent 23 obtained at the bottom of the azeotropic distillation tower was 95%, and the relevant data of the whole system are shown in Table 3.

[0049]

Embodiment 3

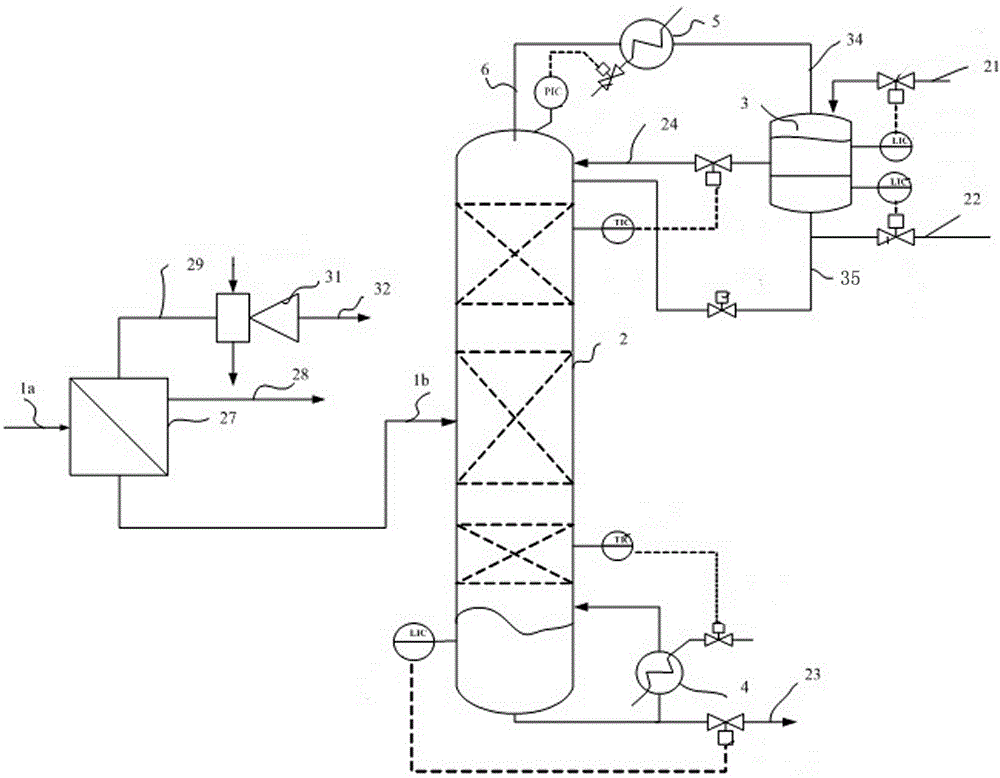

[0051] use figure 2 Described azeotropic rectification process of the present invention separates acetic acid and water, and wherein entrainer is sec-butyl acetate, and the vaporization membrane in the pervaporation membrane separator uses commercially available polydimethylsiloxane / aromatic polyamide Composite film. The dilute acetic acid stream 1 in Example 1 (Table 1) first enters the pervaporation membrane separator for processing, using 240m 2 Polydimethylsiloxane / aromatic polyamide composite membrane, keep the vaporized membrane side temperature at 267K through a jet mixer, and get 4.98kg / m 2 The water permeation flux of h, the material that does not pass through the vaporization membrane is the acetic acid enrichment stream 1b of acetic acid content close to 50wt%, then the acetic acid enrichment stream 1b enters the azeotropic rectification tower through the position of tray 18, other Implementation process is the same as embodiment 1. The stream 35 refluxed to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com