A kind of preparation method of conductive titanium dioxide powder

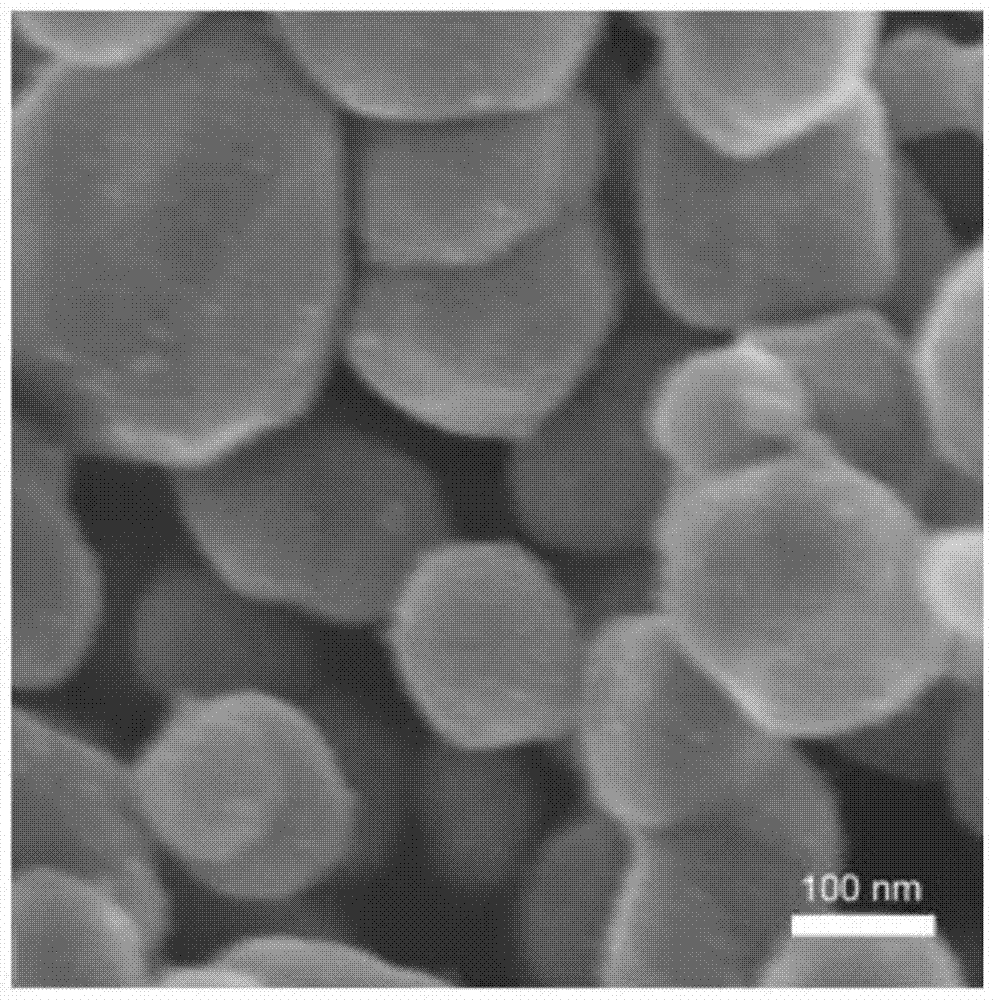

A conductive titanium dioxide, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of poor weather resistance and gloss, poor repeatability of titanium dioxide method, high cost per unit mass of product, and achieve good dispersion. , Controllable stoichiometric ratio, excellent whiteness and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the conductive titanium dioxide powder, the steps are as follows:

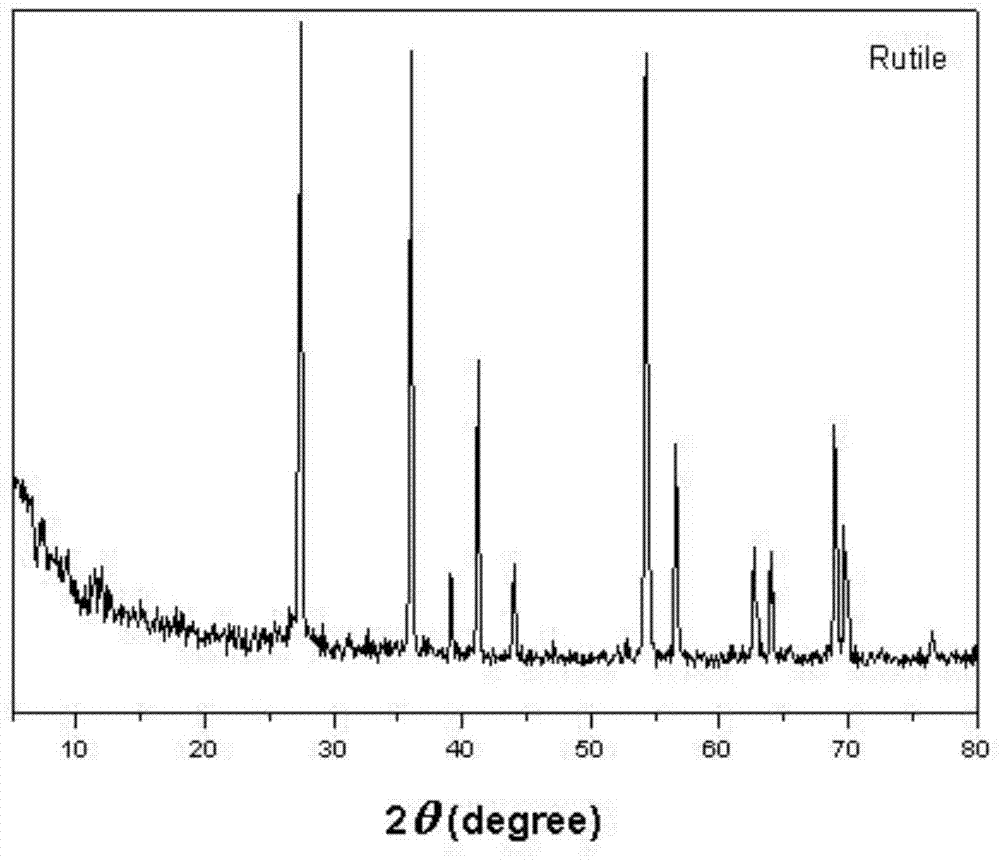

[0029] 1. Beat the rutile titanium dioxide produced by the chlorination method in distilled water, stir it evenly to obtain a slurry with a mass concentration of 20%, take 100ml, and add zirconium sulfate solution dropwise to the obtained slurry, wherein the mass of zirconium sulfate and titanium dioxide Than ZrO 2 / TiO 2 Calculated as 0.1%, the concentration of zirconium sulfate solution is ZrO 2 Count as 120g / L, obtain mixed solution A;

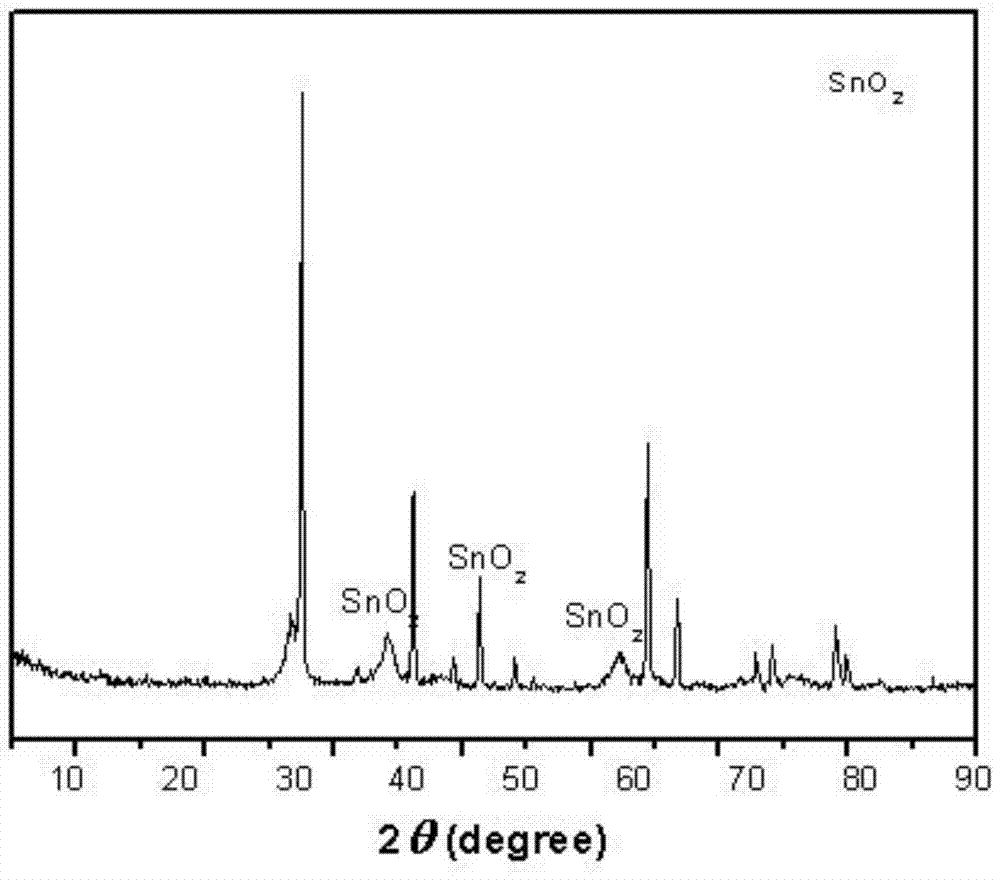

[0030] 2. Drop the mixed acid solution of tin sulfate and antimony trichloride prepared in advance into the mixed solution A at the same time, control the reaction pH=1, the reaction temperature is 60°C, the titration time is 3h, and the alkali solution is oxidized with hydrogen Sodium solution with a concentration of 6mol / L, wherein the concentration of hydrochloric acid in the mixed acidic solution is 20%, and the mass of tin sulfate is...

Embodiment 2

[0033] The preparation method of the conductive titanium dioxide powder, the steps are as follows:

[0034] 1. Beat the rutile titanium dioxide produced by the chlorination method in distilled water, stir evenly to obtain a slurry with a mass concentration of 25%, take 100ml, and add zirconium nitrate solution dropwise to the obtained slurry, wherein the mass of zirconium nitrate and titanium dioxide Than ZrO 2 / TiO 2 Calculated as 0.3%, the concentration of zirconium nitrate solution is ZrO 2 Count as 150g / L, obtain mixed solution A;

[0035]2. Drop the pre-prepared mixed acid solution of tin nitrate and antimony trichloride and potassium hydroxide solution into the mixed solution A at the same time, control the reaction pH=2, the reaction temperature is 70°C, and the titration time is 4 hours. The concentration is 8mol / L, wherein the concentration of hydrochloric acid in the mixed solution is 25%, and the mass of tin nitrate is based on SnO 2 / TiO 2 Calculated as 25%, t...

Embodiment 3

[0040] The preparation method of the conductive titanium dioxide powder, the steps are as follows:

[0041] 1. Beat the rutile titanium dioxide produced by the chlorination method in distilled water, stir evenly to obtain a slurry with a mass concentration of 30%, take 100ml, add zirconium chloride solution dropwise to the obtained slurry, wherein zirconium chloride and titanium dioxide The mass ratio of ZrO 2 / TiO 2 Calculated as 0.5%, the concentration of zirconium chloride solution is ZrO 2 Count as 180g / L, obtain mixed solution A;

[0042] 2. Drop the pre-prepared tin salt and antimony salt mixed acidic solution and alkaline solution into the mixed solution A at the same time, control the reaction pH=3, the reaction temperature is 80°C, the titration time is 5 hours, and the concentration of the ammonia solution is 10mol / L. Wherein the concentration of hydrochloric acid in the mixed solution is 30%, the quality of tin tetrachloride is by SnO 2 / TiO 2 Calculated as 30%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com