Low-temperature toughened and reinforced PC/PBT (polycarbonate/polybenzothiazole) alloy material and preparation method thereof

An alloy material and PBT resin technology, applied in the field of polymer material preparation, can solve the problems of limiting the application field of PC/PBT alloy material, the influence of toughening effect and strengthening effect, toughness and strength not meeting requirements, etc. Improve, improve anti-aging, improve the effect of surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

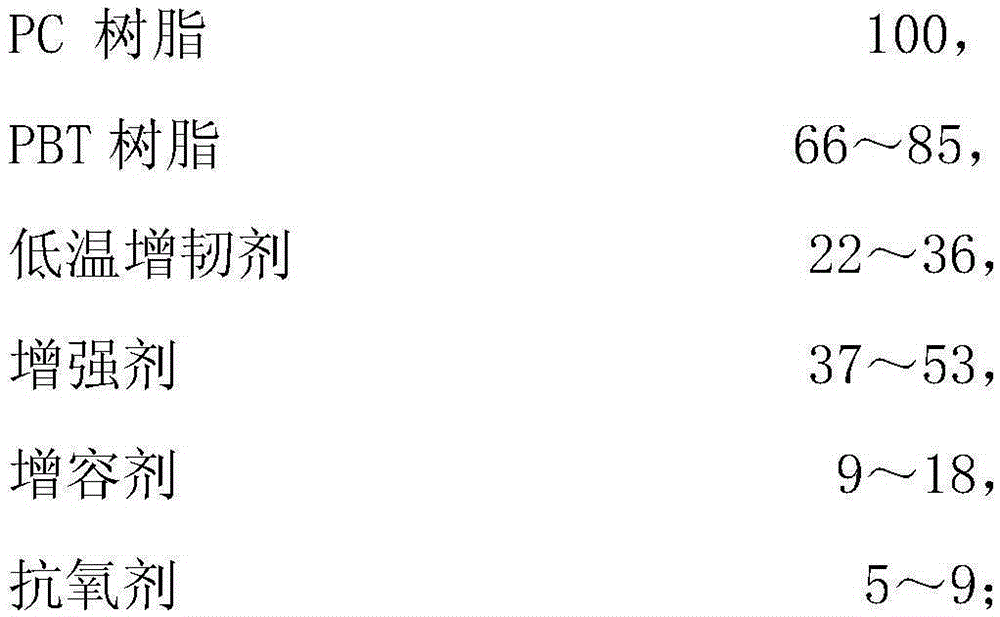

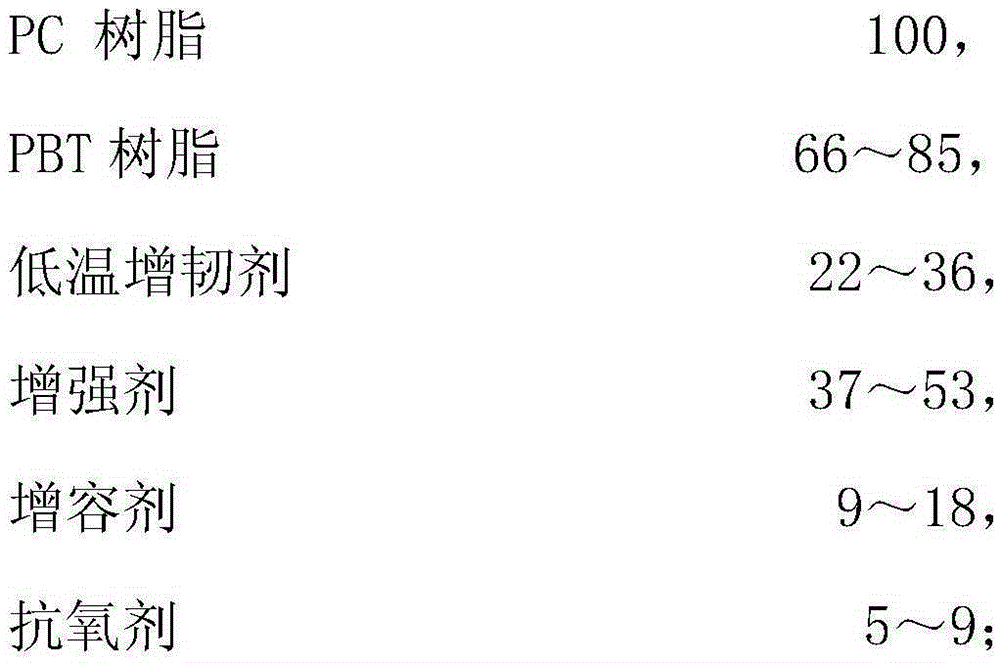

Method used

Image

Examples

Embodiment 1

[0026] Get 100 parts of PC resin, 72 parts of PBT resin, 42 parts of reinforcing agent alkali-free chopped glass fiber, 26 parts of toughening agent MBS, 11 parts of compatibilizer EMA and 5 parts of antioxidant, wherein antioxidant consists of antioxidant 1010 and Antioxidant 168 is compounded at a ratio of 50:50.

[0027] The process parameters of the extruder are as follows:

[0028] No. 1 extruder (single-screw extruder): the temperature of zone 1 is 235°C, the temperature of zone 2 is 245°C, the temperature of zone 3 is 255°C, the temperature of zone 4 is 265°C, the temperature of zone 5 is 275°C, the temperature of zone 6 is 280°C, the temperature of zone 7 is 280°C, The zone temperature is 280°C, the head temperature is 285°C; the screw speed is 330r / min; the feeding frequency of the main feeding port is 15Hz, and the feeding frequency of the side feeding port is 3.5Hz;

[0029] No. 2 extruder (co-rotating twin-screw extruder): the temperature of zone 1 is 190°C, the t...

Embodiment 2

[0039] Get 100 parts of PC resin, 75 parts of PBT resin, 48 parts of reinforcing agent alkali-free chopped glass fiber, 30 parts of toughening agent MIS, 15 parts of compatibilizer EMA and 7 parts of antioxidant, wherein antioxidant consists of antioxidant Oxygen 1010 and antioxidant 168 are compounded at a ratio of 60:40.

[0040] The process parameters of the extruder are as follows:

[0041] No. 1 extruder (single-screw extruder): the temperature of zone 1 is 240°C, the temperature of zone 2 is 250°C, the temperature of zone 3 is 260°C, the temperature of zone 4 is 270°C, the temperature of zone 5 is 280°C, the temperature of zone 6 is 285°C, the temperature of zone 7 is 285°C, The zone temperature is 285°C, the head temperature is 290°C, the screw speed is 280r / min, the feeding frequency of the main feeding port is 15Hz, and the feeding frequency of the side feeding port is 3.7Hz;

[0042] No. 2 extruder (co-rotating twin-screw extruder): the temperature of zone 1 is 180°...

Embodiment 3

[0052] Get 100 parts of PC resin, 81 parts of PBT resin, 53 parts of reinforcing agent alkali-free chopped glass fiber, 36 parts of toughening agent MBS, 17 parts of compatibilizer EMA and 9 parts of antioxidant, wherein antioxidant consists of antioxidant Oxygen 1010 and antioxidant 168 are compounded at a ratio of 70:30.

[0053] The process parameters of the extruder are as follows:

[0054] No. 1 extruder (single-screw extruder): the temperature of the first zone is 245°C, the temperature of the second zone is 255°C, the temperature of the third zone is 265°C, the temperature of the fourth zone is 275°C, the temperature of the fifth zone is 285°C, the temperature of the sixth zone is 290°C, the temperature of the seventh zone is 290°C, The zone temperature is 290°C, the head temperature is 295°C, the screw speed is 220r / min, the feeding frequency of the main feeding port is 15Hz, and the feeding frequency of the side feeding port is 3.9Hz;

[0055] No. 2 extruder (co-rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com