Phthalonitrile modified benzoxazine and epoxy resin composite material, preparation and application

A technology of phthalonitrile and epoxy resin, which is applied in the direction of organic chemistry, can solve the problems of insufficient thermal stability, high brittleness of cured products, high curing reaction temperature, etc., and achieve high yield, shortened synthesis cycle, and preparation method easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

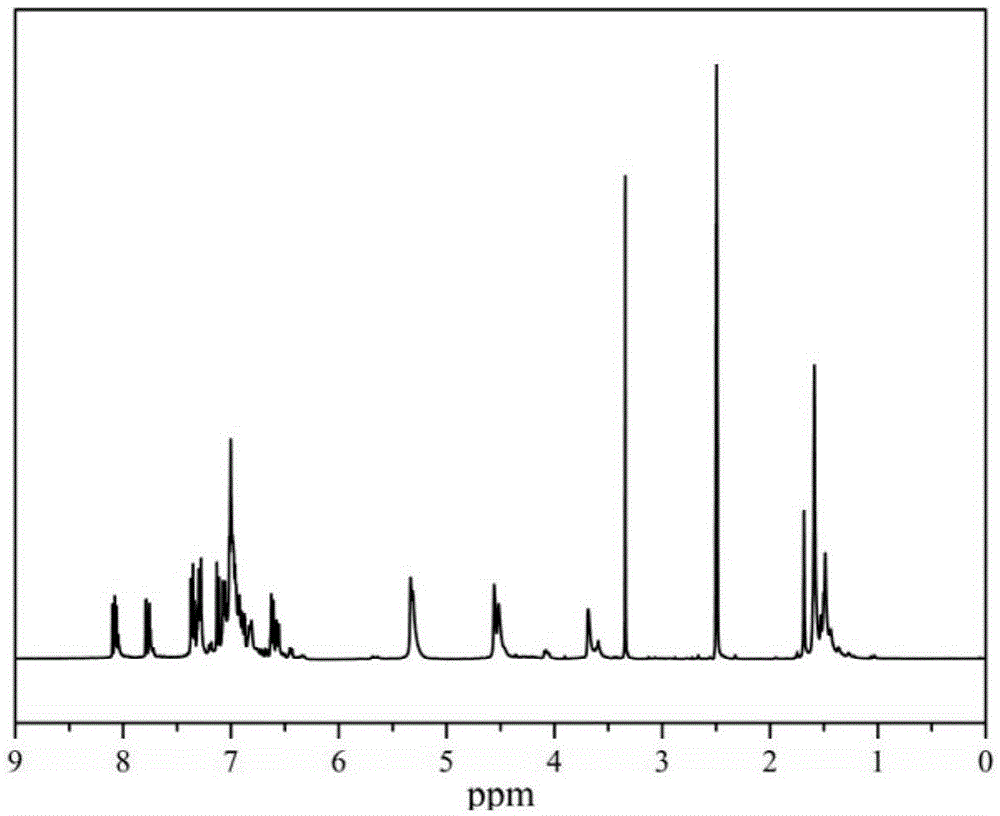

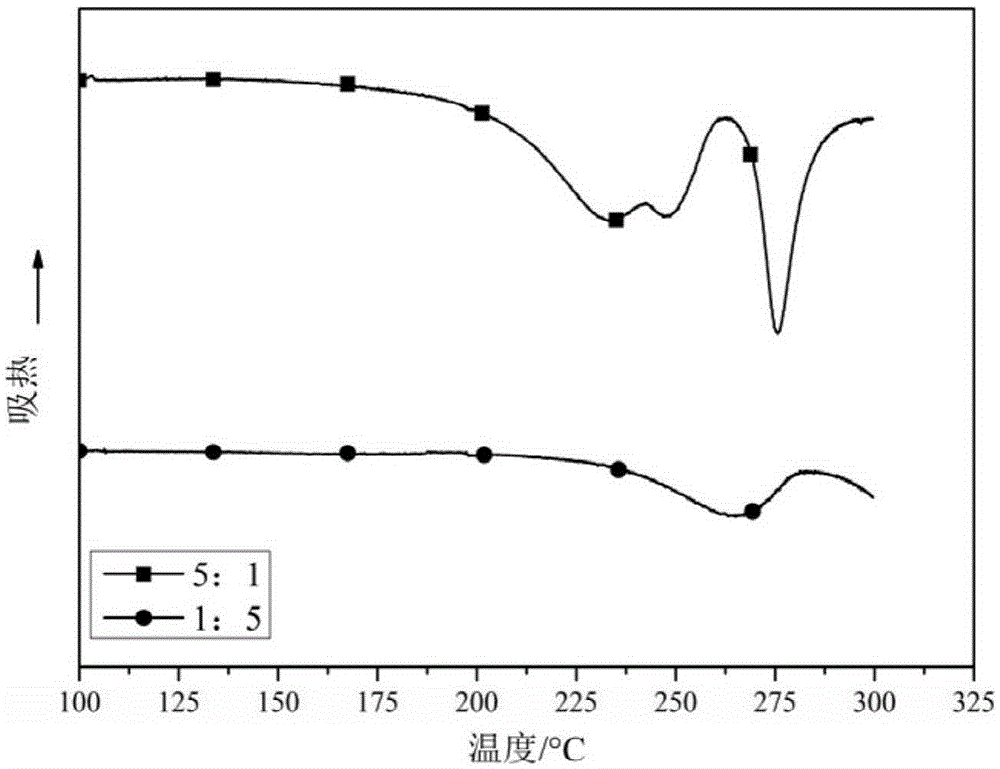

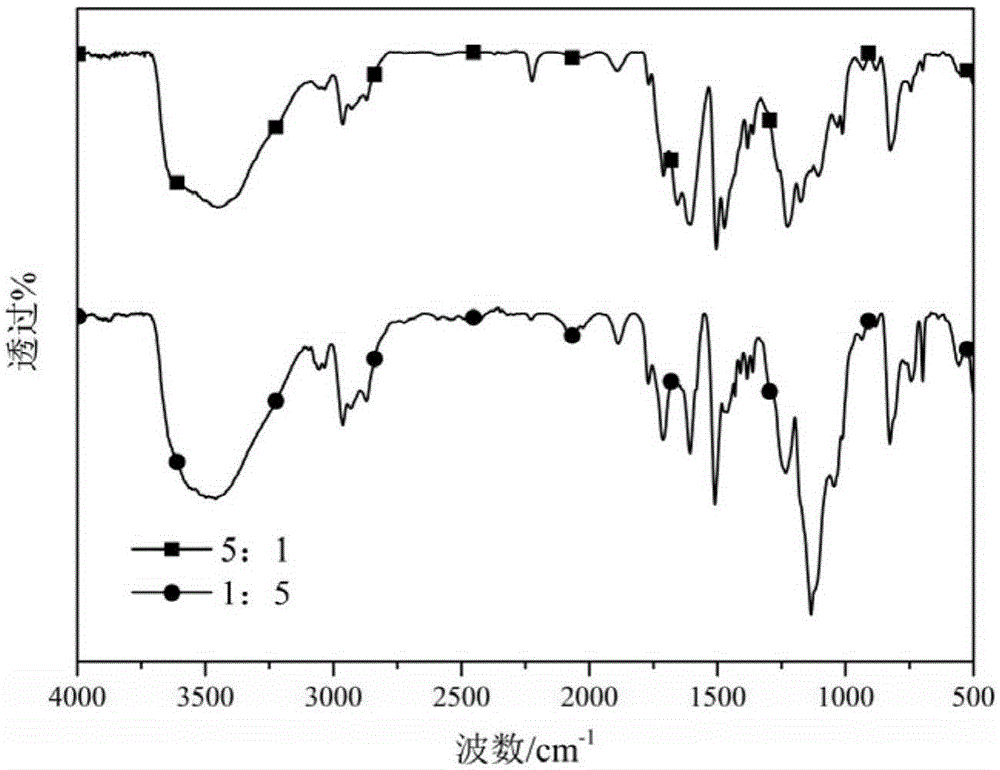

Embodiment 1

[0041] Add 9.91g (0.05mol) of 4,4'-diaminodiphenylmethane, 6.00g (0.20mol) of paraformaldehyde and 250mL of chloroform into a 500mL flask equipped with a magnetic stirrer. The mixture was stirred under ice bath for 30 minutes, then 22.83 g (0.10 mol) of bisphenol A was added, and then the temperature was gradually raised to 60° C. for reflux and maintained for 12 hours. After the reaction dropped to room temperature, anhydrous sodium sulfate was added, dried for 12 hours and then filtered. The filtrate was evaporated to remove the solvent, and the residue was dissolved in 250 mL of dry DMF. After the dissolution was complete, 17.31 g (0.10 mol) of 4-nitrate was added in turn. Base phthalonitrile and 27.64g (0.20mol) of anhydrous potassium carbonate, add and stir at room temperature for 24 hours. After the reaction was completed, the reaction mixture was poured into a large amount of water to precipitate, and the precipitate was collected by filtration and washed with water and...

Embodiment 2

[0044]Add 9.91 g (0.05 mol) of 4,4'-diaminodiphenylmethane, 6.00 g (0.20 mol) of paraformaldehyde and 250 mL of dioxane into a 500 mL flask equipped with a magnetic stirrer. The mixture was stirred in an ice bath for 30 minutes, then 22.83 g (0.10 mol) of bisphenol A was added, and then the temperature was gradually raised to 100° C. for reflux and maintained for 8 hours. After the reaction dropped to room temperature, anhydrous sodium sulfate was added, dried for 12 hours and then filtered. The filtrate was evaporated to remove the solvent, and the residue was dissolved in 250 mL of dry DMF. After the dissolution was complete, 17.31 g (0.10 mol) of 4-nitrate was added in turn. Base phthalonitrile and 27.64g (0.20mol) of anhydrous potassium carbonate, after the addition was completed, the mixture was stirred and reacted at 60°C for 6 hours. After the reaction was completed, the reaction mixture was poured into a large amount of water to precipitate, and the precipitate was col...

Embodiment 3

[0046] Add 9.91 g (0.05 mol) of 4,4'-diaminodiphenylmethane, 6.00 g (0.20 mol) of paraformaldehyde and 250 mL of dimethyl sulfoxide into a 500 mL flask equipped with a magnetic stirrer. The mixture was stirred under ice bath for 30 minutes, then 22.83 g (0.10 mol) of bisphenol A was added, and then the temperature was gradually raised to 120° C. for 6 hours. Add anhydrous sodium sulfate after the reaction is lowered to room temperature, filter after drying for 12 hours, obtain the DMSO solution of the product, then add 17.31g (0.10mol) 4-nitrophthalonitrile and 43.25g (0.20mol) to it successively After the addition of anhydrous tripotassium phosphate, stir and react at room temperature for 24 hours. After the reaction was completed, the reaction mixture was poured into a large amount of water to precipitate, and the precipitate was collected by filtration and washed with water and ethanol several times to remove impurities. The compound of general formula 1 was obtained, 38.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com