Cage-shaped oligomerization silsesquioxane hybridized phenolic resin with eight phenolic hydroxyl groups and preparation method thereof

The technology of polysilsesquioxane and octaphenol hydroxyl cage is applied in the field of octaphenol hydroxyl cage oligomeric silsesquioxane hybrid phenolic resin and its preparation, and can solve the problem of increasing the thermal and mechanical properties of resin, POSS Agglomeration, affecting performance and other problems, to achieve the effect of increasing thermal properties and tensile properties, improving oxidation resistance, and improving inherent properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

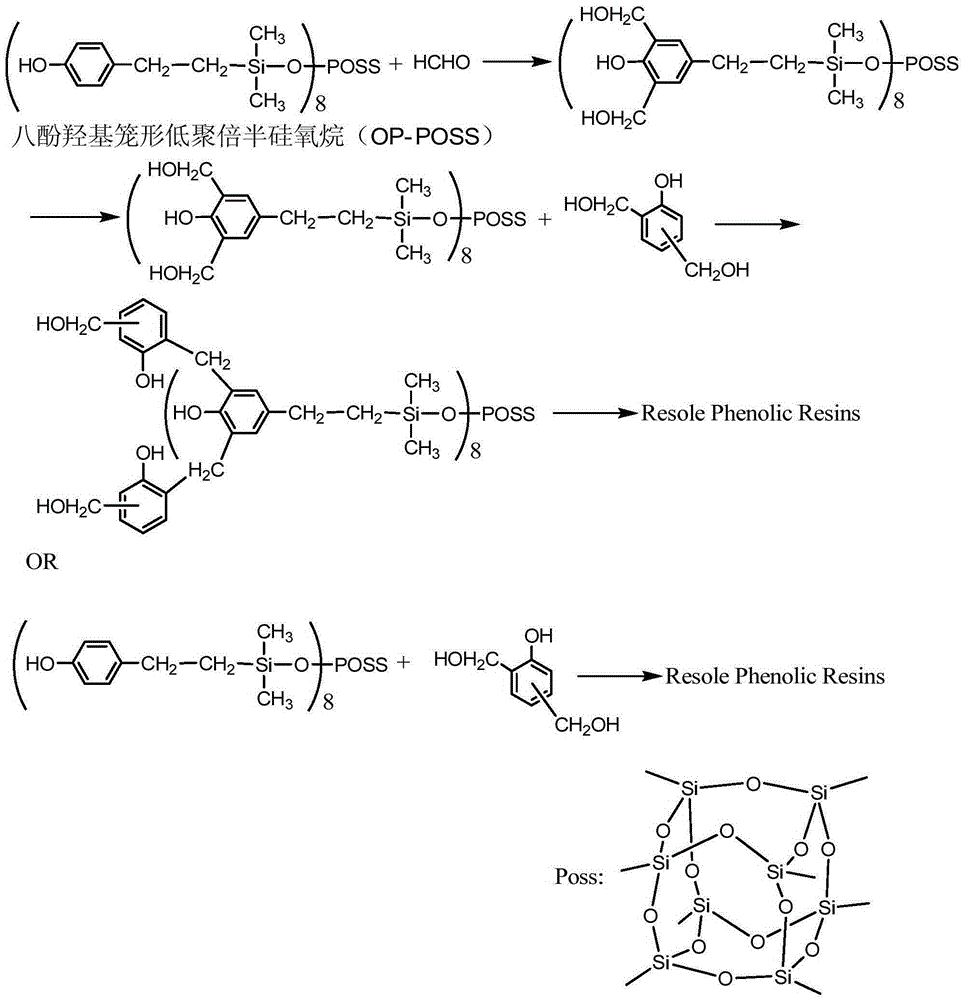

[0043] The preparation method of octaphenol hydroxyl cage oligomeric silsesquioxane hybridized thermosetting phenolic resin of the present invention comprises the following steps:

[0044] (1), dissolve 100~200 parts of phenols in 85~175 parts of formaldehyde solution by mass ratio, add 1~50 parts of octaphenol hydroxyl cage oligomeric silsesquioxane as reactants, 40~50 ℃ Stir in a water bath for 10 to 30 minutes, then add 0.2 to 3 parts of barium hydroxide octahydrate to adjust the pH of the solution to 8 to 9, slowly heat up to 60 to 70°C, and carry out a constant temperature reaction for 1 to 3 hours; the heating rate is 0.16 to 0.33°C / min;

[0045] (2), slowly warming up the solution obtained in step (1) from 60~70 ℃ to 85~98 ℃, carry out constant temperature reaction 1~3h, and heating rate is 0.16~0.33 ℃ / min;

[0046] (3), add 0.3~3.5 parts of phosphoric acid solution, adjust the pH value of the solution obtained in step (2) to be 5~6, after stirring for 10~20min, under...

Embodiment 1

[0068] According to mass parts, 130 parts of phenol were dissolved in 140 parts of formaldehyde solution, and 20 parts of octaphenol hydroxyl clathrate oligomeric silsesquioxane were added, stirred in a water bath at 40°C for 30 minutes, and then 1.4 parts of barium hydroxide octahydrate was added to adjust the solution The pH value of the solution is 8 to 9, and the temperature is slowly raised to 60 °C, and the constant temperature reaction is carried out for 3h; the heating rate is 0.25 °C / min; the mass concentration of the formaldehyde solution is 37%.

[0069] The above solution was slowly heated from 60°C to 95°C, and a constant temperature reaction was carried out for 1 h, and the heating rate was 0.25°C / min;

[0070] Add 1.6 parts of phosphoric acid solution, adjust the pH value of the above solution to 5-6, stir for 15 minutes, stir and dehydrate in a water bath at 95°C for 1 hour under vacuum conditions, stand, precipitate, filter, cool to room temperature, and take o...

Embodiment 2

[0080] According to parts by mass, dissolve 100 parts of phenol in 85 parts of formaldehyde solution, add 1 part of octaphenolic hydroxyl clathrate oligomeric silsesquioxane, stir in a water bath at 40°C for 30 minutes, and then add 0.2 parts of barium hydroxide octahydrate to adjust the solution The pH value of the mixture is 8-9, and the temperature is slowly raised to 60° C., and the constant temperature reaction is carried out for 1-3 hours; the heating rate is 0.16° C. / min; the mass concentration of the formaldehyde solution is 35%.

[0081] Slowly raise the temperature of the above solution from 60°C to 95°C, carry out constant temperature reaction for 1 hour, and the heating rate is 0.16°C / min;

[0082] Add 0.3 parts of phosphoric acid solution, adjust the pH value of the above solution to 5-6, stir for 15 minutes, and dehydrate in a water bath at 95°C under vacuum for 3 hours, let stand, precipitate, filter, cool to room temperature, and take out the upper layer of pure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotational viscosity | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com