A positive linear capacity temperature change rate medium material and its preparation method

A technology of capacity temperature change rate and dielectric material, which is applied in the field of functional ceramic materials, can solve the problems of large dielectric loss of ceramics, decrease in capacitor capacity, and increase in capacitor temperature, so as to improve insulation resistivity, reduce dielectric loss, and increase density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

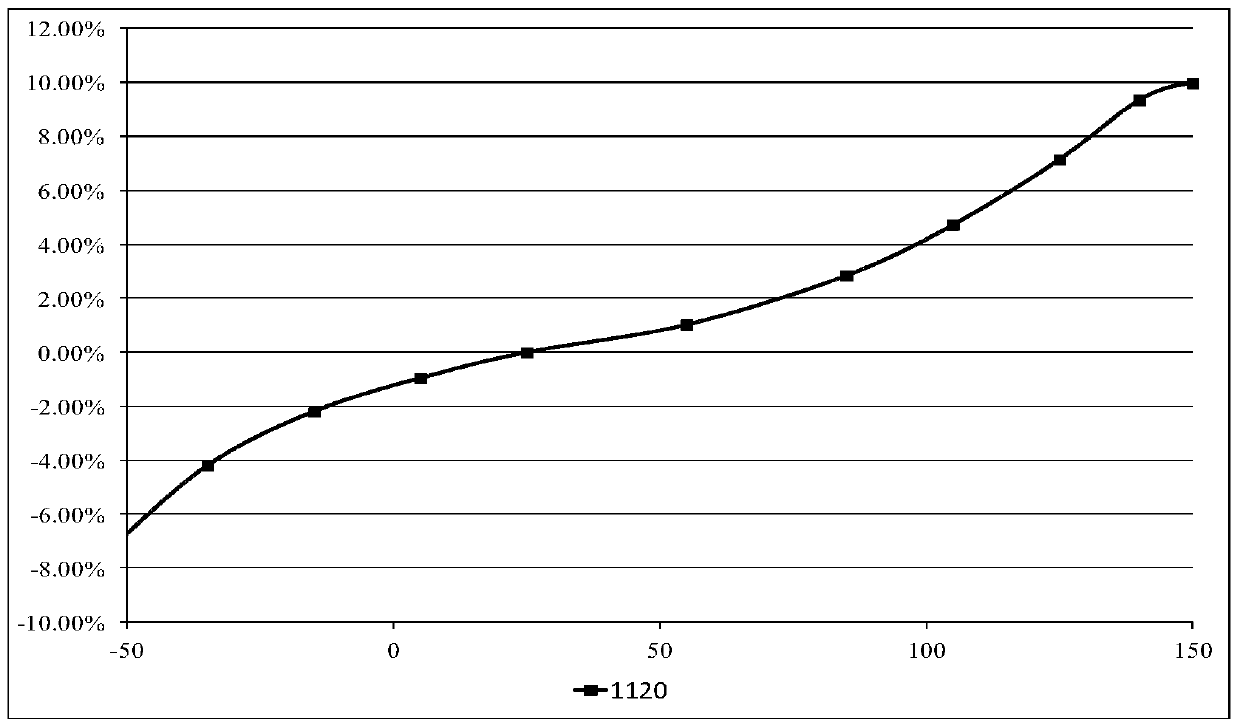

Image

Examples

Embodiment 1

[0029] (1) Weigh 52.26g Bi 2 o 3 , 11.89g Na 2 CO 3 and 35.85g TiO 2 , mixed ball milling, sieving, and calcining at 800°C for 4 hours to synthesize sodium bismuth titanate; the sodium bismuth titanate is mainly Bi 0.5 Na 0.5 TiO 3 , containing a small amount of Bi 0.6 Na 0.4 TiO 3 and Bi 0.4 Na 0.6 TiO 3 . The same goes for other embodiments.

[0030] (2) 92.68g barium titanate and 7.32g bismuth sodium titanate were weighed, mixed by ball milling, dried, crushed through a 40-mesh sieve, and calcined at 1200°C for 3 hours to synthesize a eutectic compound;

[0031] (3) Weigh 79.03g Bi 2 o 3 , 20.97g H 3 BO 3 , mixed by ball milling with alcohol as the medium, dried, crushed through a 40-mesh sieve, and calcined at 400°C for 4 hours to synthesize BiBO 3 ;

[0032] (4) Accurately weigh the compound prepared by 97.65g step (2), 1.682g Nb 2 o 5 , 0.426g Nd 2 o 3 , 0.242gMnCO 3 、2g BiBO 3 Proceed to the ingredients. Grind for 6 hours with 2 mm zirconium ba...

Embodiment 2

[0034] (1) Weigh 52.26g Bi 2 o 3 , 11.89g Na 2 CO 3 and 35.85g TiO 2 , mixed ball milling, sieving, and calcining at 900°C for 2 hours to synthesize sodium bismuth titanate;

[0035] (2) Weigh 93.6g of barium titanate and 6.4g of bismuth sodium titanate, mix them by ball milling, dry them, crush them through a 40-mesh sieve, and calcinate at 1140°C for 6 hours to synthesize a eutectic compound;

[0036] (3) Weigh 79.03g Bi 2 o 3 , 20.97g H 3 BO 3 , mixed by ball milling with alcohol as the medium, dried, crushed through a 40-mesh sieve, and calcined at 400°C for 4 hours to synthesize BiBO 3 ;

[0037] (4) Accurately weigh the compound prepared in 97.6g step (2), 1.679g Nb 2 o 5 , 0.483g Er 2 o 3 , 0.242gMnCO 3 , 2.5g BiBO 3 , for batching. Grind for 6 hours with 2mm yttrium stabilized zirconium balls, dry and pass through an 80-mesh standard sieve, add 6-7% paraffin to fry and granulate, and then pass through an 80-mesh standard sieve again. Press the granulated...

Embodiment 3

[0039] (1) Weigh 52.26g Bi 2 o 3 , 11.89g Na 2 CO 3 and 35.85g TiO 2 , mixed ball milling, sieving, and calcining at 850°C for 3 hours to synthesize sodium bismuth titanate;

[0040] (2) Weigh 91.76g of barium titanate and 8.24g of bismuth sodium titanate, mix them by ball milling, dry, crush and pass through a 40-mesh sieve, and calcinate at 1140°C for 2 hours to synthesize a eutectic compound;

[0041] (3) Weigh 79.03g Bi 2 o 3 , 20.97g H 3 BO 3 , mixed by ball milling with alcohol as the medium, dried, crushed through a 40-mesh sieve, and calcined at 400°C for 4 hours to synthesize BiBO 3 ;

[0042] (4) Accurately weigh the compound prepared in 97.48g step (2), 2.016g Nb 2 o 5 , 0.161g Er 2 o 3 , 0.339gMnCO 3 , 2.5g BiBO 3 , for batching. Grind for 6 hours with 2mm yttrium stabilized zirconium balls, dry and pass through an 80-mesh standard sieve, add 6-7% paraffin to fry and granulate, and then pass through an 80-mesh standard sieve again. Press the granul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com