Marine diesel engine low temperature selective catalytic reduction system titanium-based catalyst and preparation method thereof

A marine diesel engine and selective technology, which is used in the preparation of SCR system catalysts, and in the field of low-temperature SCR system catalysts for marine diesel engines, can solve the problems of high active temperature, easy blockage and deactivation, and high activity, achieve good low-temperature activity, and improve anti-sulfur activity. , The effect of good anti-sulfur performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

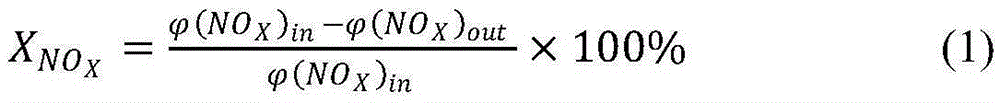

Method used

Image

Examples

Embodiment Construction

[0026] The following examples describe the present invention in more detail.

[0027] Titanium-based catalyst for low-temperature SCR system of marine diesel engine, including carrier and active components.

[0028] The carrier is a composite carrier prepared from carbon nanotubes and titanium nanotubes, and the active component is manganese metal oxide (MnO X ).

[0029] The carbon nanotubes are multi-walled carbon nanotubes (MCNTs), and the titanium nanotubes are P 25 (TiO 2 , degussa) titanium nanotubes (TNTs) synthesized by hydrothermal method.

[0030] The manganese metal oxide (MnO X ) for MnO 2 and Mn 2 o 3 One or a mixture of two, MnO X with TiO 2 The molar proportion of MnO X :TiO 2 = 0.4.

[0031] The transition metal element cerium (Ce) is added to the catalyst, and the mass ratio of the cerium atoms in the catalyst to the titanium atoms in the TNTs is Ce:Ti=0.5.

[0032] The preparation method of the titanium-based catalyst of the low-temperature SCR s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com