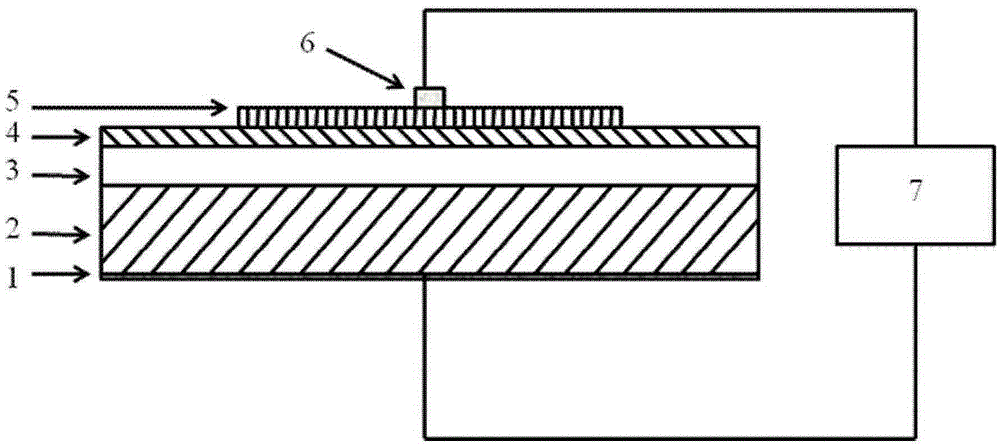

Ultraviolet detector based on palladium/tin dioxide/silicon heterojunction and preparation method thereof

A tin dioxide and silicon heterojunction technology, used in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of difficult preparation technology, inability to be popularized and applied, and expensive single crystal semiconductor thin film equipment. , to achieve the effect of suitable for mass production, short recovery time and easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] We selected a p-type monocrystalline silicon wafer with a thickness of 0.5 mm as the substrate, and retained its natural oxide layer. Clean the silicon wafer in ultrasonic wave with deionized water for 10 minutes, then wash the silicon wafer in ultrasonic wave with acetone for 1 hour, and finally clean the silicon wafer with absolute ethanol for 0.5 hour.

[0026] Tin dioxide film was prepared by DC magnetron sputtering: put the cleaned silicon substrate into the sputtering chamber, and turn on the vacuum system for vacuuming; when the background vacuum was 2.0×10 -4 At Pascal, argon / oxygen mixed gas is introduced, the ratio of the two gases is 1:1, and the pressure is maintained at 5 Pascals. After the pressure is stable, the tin target is sputtered. The sputtering power is 90 watts, and the sputtering time is For 10 minutes, the substrate temperature was room temperature. A tin dioxide film with a thickness of about 70 nm is formed on the silicon wafer. After the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com