Preparation method of graphene/carbon nano tube co-reinforced conducting polymer hydrogel

A conductive polymer, carbon nanotube technology, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of difficult to obtain high specific capacitance, small effective specific surface area of composite materials, etc., to facilitate the expansion of scale. Production, improvement of ion/electron transport ability and chemical stability, effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

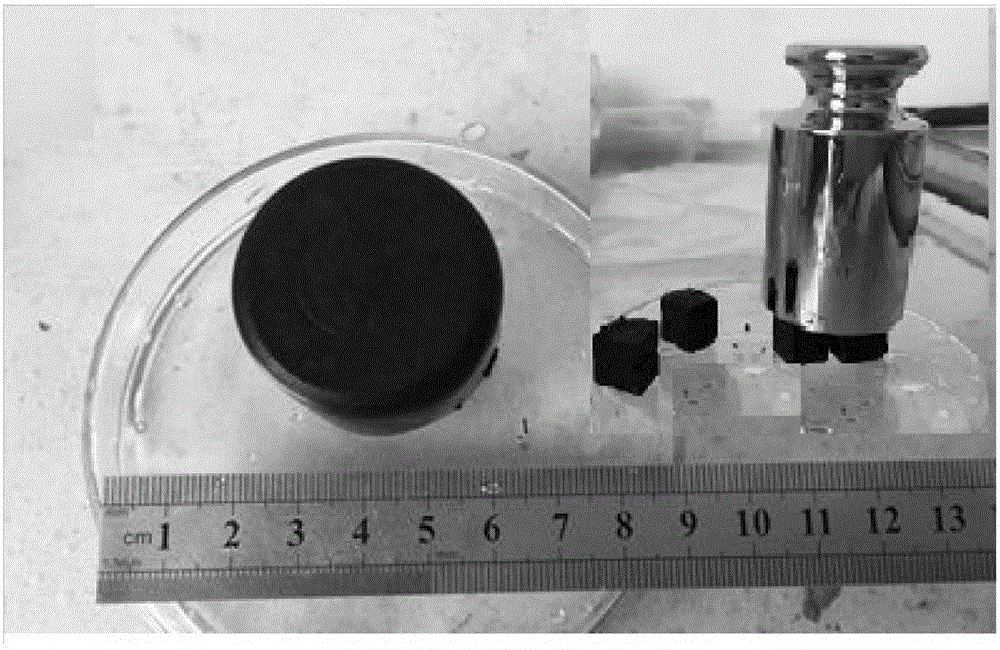

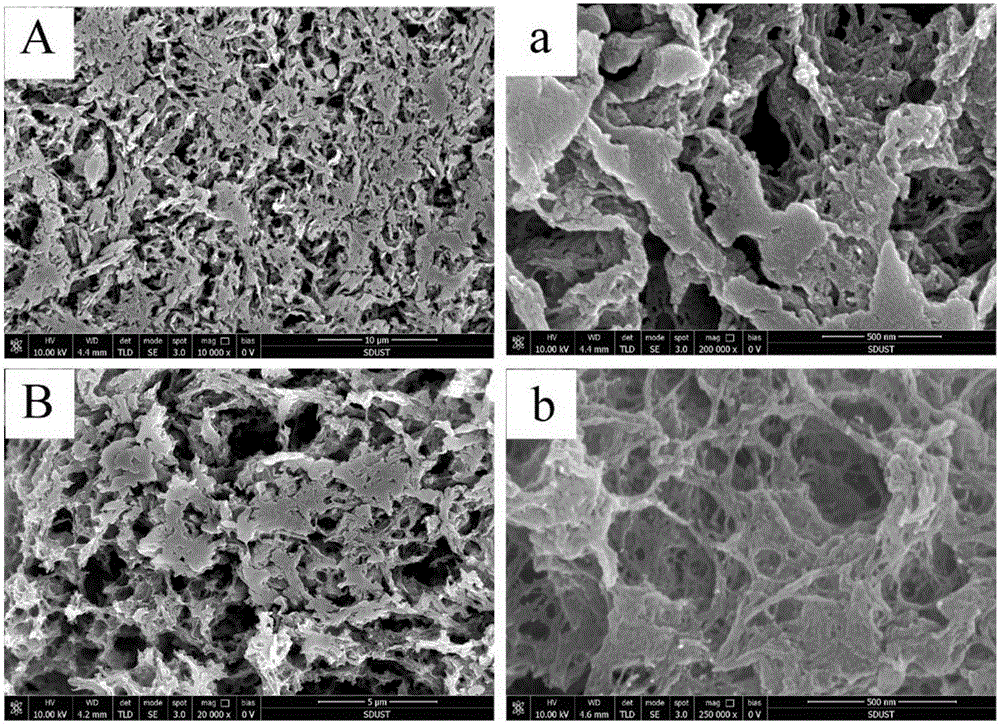

[0032] A preparation method of graphene / carbon nanotubes co-reinforced conductive polymer hydrogel, the steps are as follows:

[0033] (1) At room temperature, dissolve 0.412g (0.1M) sodium polystyrene sulfonate (purchased from Aldrich, Germany) in 20mL0.05mg / mL graphene oxide solution (see HummersWS, OffemanRE.Preparationofgraphiteoxide.JAmChemSoc, 1958 for the preparation method ,80:1339), stirred and dispersed using ultrasound to form a solution.

[0034] (2) Add 10 mg of carboxylated carbon nanotubes (purchased from Shenzhen Nanoport Co., Ltd.) into the above aqueous solution, stir and disperse by ultrasonic waves to form a dispersion liquid.

[0035] (3) Add 110 μL (1 mmol) of 3,4-ethylenedioxythiophene monomer (purchased from Suzhou Yake Chemical Reagent Co., Ltd.) into the above dispersion liquid, stir and disperse with ultrasonic waves to form a reaction system;

[0036] (4) 12.12gFe(NO 3 )3 9H 2 O (30mmol, purchased from Sinopharm Chemical Reagent Co., Ltd.) was di...

Embodiment 2

[0049] A kind of preparation method of Graphene / carbon nanotube reinforced conductive polymer hydrogel, its difference with embodiment 1 is that the quality of polystyrene sodium sulfonate becomes 0.824g (0.2M) by 0.412g (0.1M) M), the concentration of graphene oxide was changed from 0.05 mg / mL to 0.1 mg / mL, and 10 mg carboxylated carbon nanotubes were changed to 10 mg acidified carbon nanotubes (the carbon nanotubes were refluxed in concentrated nitric acid at 80 ° C for 12 h) 110 μL (1 mmol )3,4-ethylenedioxythiophene monomer was changed to 210 μL (3 mmol) pyrrole, and the standing reaction changed from 8h to 12h.

Embodiment 3

[0051] A kind of preparation method of Graphene / carbon nanotube reinforced conductive polymer hydrogel, its difference with embodiment 1 is that the quality of sodium polystyrene sulfonate becomes 1.236g (0.3g) by 0.412g (0.1M) M), the concentration of graphene oxide becomes 0.5mg / mL by 0.05mg / mL, and 10mg carboxylated carbon nanotubes become 10mg epoxidized carbon nanotubes (preparation method is referring to Ogrin, D., Chattopadhyay, J, Sadana, A.K, Billups, W.E, Barron, A.R. Epoxidation and deoxygenation of single-walled carbon nanotubes: Quantification of epoxy defects. JAmChemSoc, 2006, 128, 11322-11323.) 110 μ L (1 mmol) 3,4-ethylenedioxythiophene monomer into 540 μ L (5 mmol) aniline, static The reaction was changed from 8h to 18h, the purification equilibrium time was changed from 3 days to 5 days, and the soaking time of the hydrogel in hydroiodic acid was changed from 12h to 18h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com