Method for preparing high performance carboxylic acrylonitrile butadiene rubber latexes

A carboxylated nitrile latex, a high-performance technology, applied in the field of emulsion polymerization in polymer materials, can solve problems such as insufficient odor, and achieve the effects of good fluidity, moderate viscosity, and improved bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Preparation of seed latex

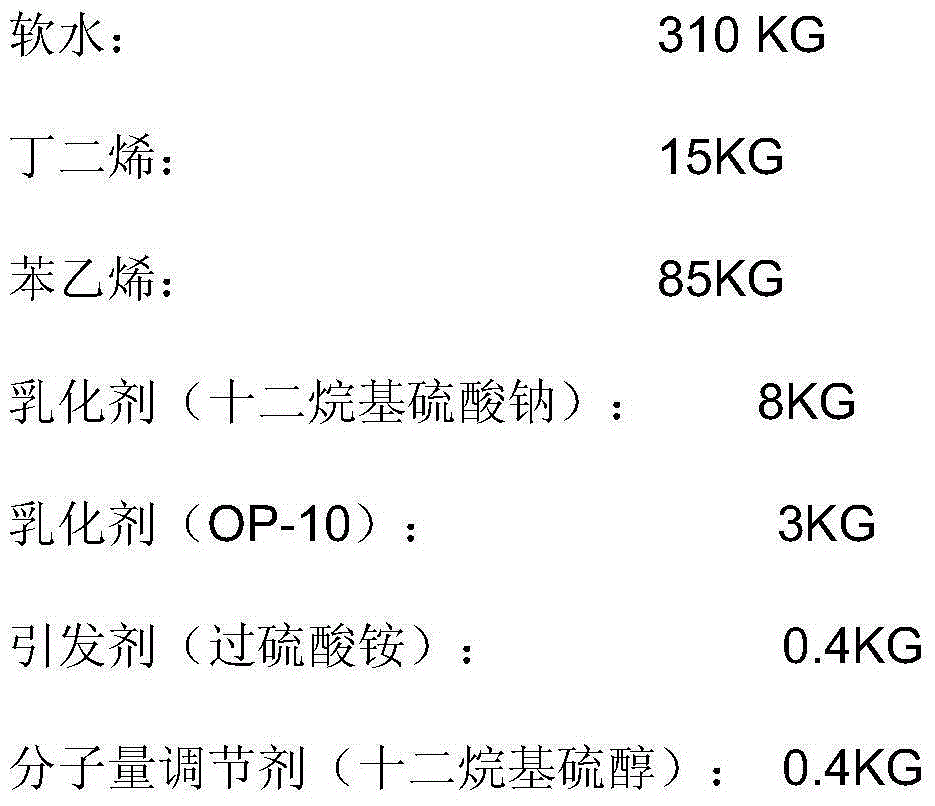

[0036] Seed Latex A: The 500L polymerization kettle is evacuated first, and the vacuum degree reaches -0.1MPa, and the material is fed according to the following formula:

[0037]

[0038]

[0039] Raise the temperature to 52°C, react for 12 hours, the conversion rate is 98%, cool down and discharge to obtain seed latex A with a solid content of 28.2%, a particle size of 43nm, and an aggregate of less than 0.05%.

[0040] Seed Latex B: The 500L polymerization kettle is evacuated first, and the vacuum degree reaches -0.1MPa, and the material is fed according to the following formula:

[0041]

[0042] Raise the temperature to 48°C, react for 14 hours, the conversion rate is 99%, cool down and discharge to obtain seed latex B, with a solid content of 26.1%, a particle size of 48nm, and an aggregate of less than 0.01%.

[0043] Seed Latex C: The 500L polymerization kettle is evacuated first, and the vacuum degree reaches -0.1MPa, and t...

Embodiment 1

[0048] Example 1: The 300L polymerization kettle is first evacuated, and the vacuum reaches -0.1MPa, and then 119KG of soft water, seed latex A10KG, acrylonitrile 20KG, butadiene 50KG, methacrylic acid 1KG, sodium vinylsulfonate 1KG, ten Sodium dialkylsulfate 1KG, divinylbenzene 0.5KG, initiator 0.4KG, a small amount of electrolyte, chelating agent, pH buffer, heat up, and emulsify the following components by ultrasonic or homogenizer to obtain a stable fine emulsion :

[0049]

[0050] When the temperature reaches 50°C, add the components of the above mini-emulsion dropwise at the same time for 2.5 hours, and control the temperature at about 50°C during the dropwise addition. Insulate and react for 3 hours, when the conversion rate reaches more than 99%, degassing treatment is carried out to remove unreacted monomers, adding lye to adjust the pH value to between 7 and 8, cooling down and discharging the material for packaging, and a kind of High-performance carboxylated n...

Embodiment 2

[0051] Example 2: The 300L polymerization kettle is first evacuated, and the vacuum reaches -0.1MPa, and then 115KG of soft water, seed latex B12KG, acrylonitrile 18KG, butadiene 52KG, methacrylic acid 1KG, sodium vinylsulfonate 0.5KG, Sodium lauryl sulfate 1KG, divinylbenzene 1KG, initiator 0.4KG, a small amount of electrolyte, chelating agent, PH buffering agent, heat up, and emulsify the following components by ultrasonic or homogenizer to obtain a stable fine emulsion :

[0052]

[0053]

[0054] When the temperature reaches 50°C, add the components of the above mini-emulsion dropwise at the same time for 3 hours, and control the temperature at about 55°C during the dropwise addition. Insulate and react for 3 hours, when the conversion rate reaches more than 99%, degassing treatment is carried out to remove unreacted monomers, adding lye to adjust the pH value to between 7 and 8, cooling down and discharging the material for packaging, and a kind of High-performance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com