Method and device capable of continuously preparing nitrous acid ester

A technology of nitrite and nitrite, applied in the chemical industry, can solve problems such as large inorganic salts, waste water, and tail gas pollution safety hazards, and achieve the effect of small equipment investment, low energy consumption, and elimination of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

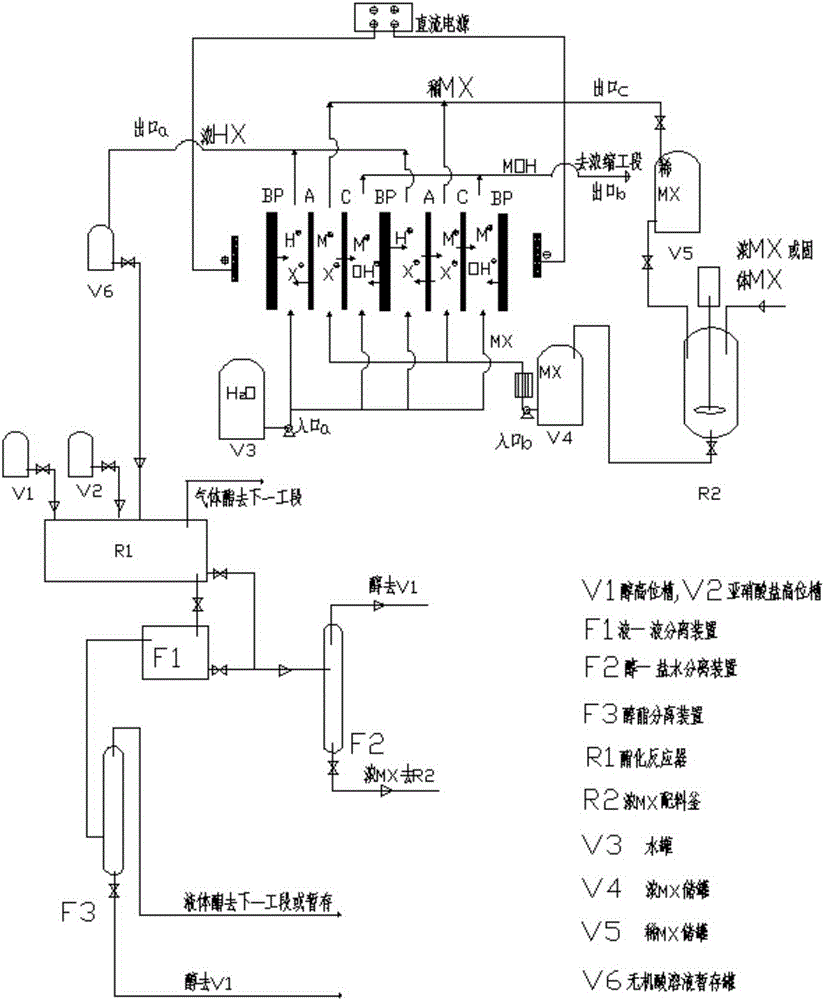

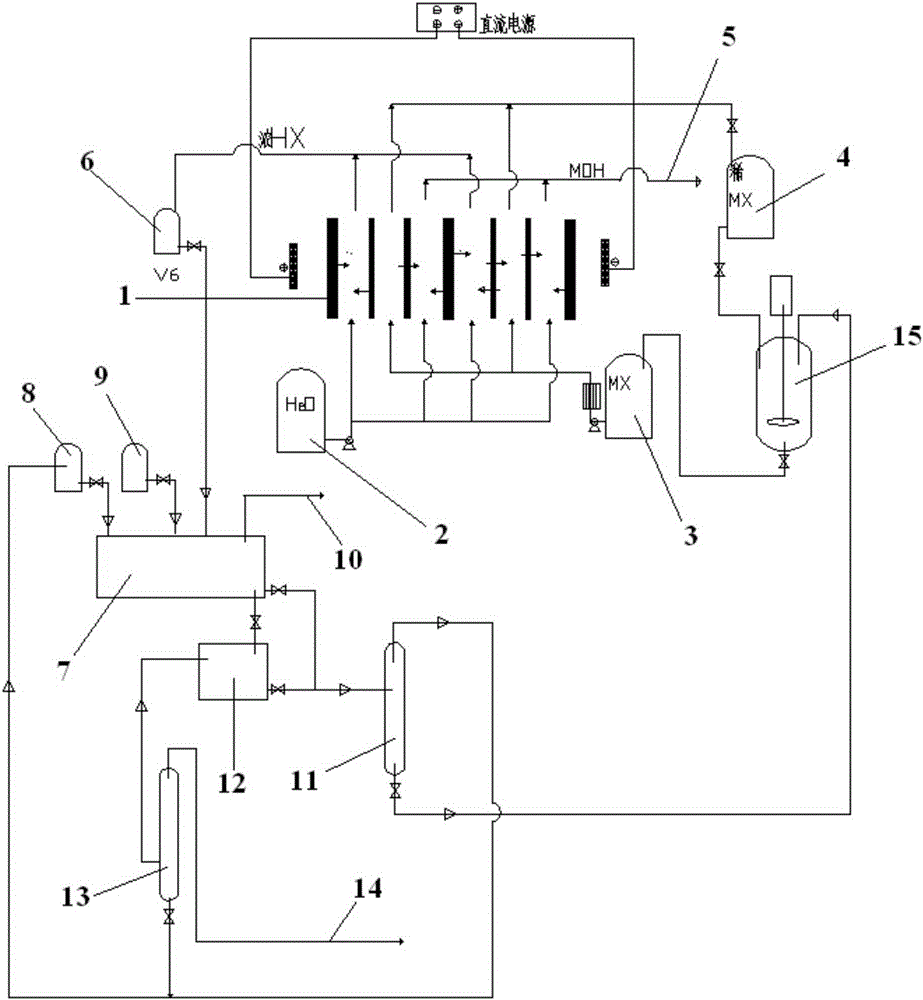

[0036] This embodiment provides a kind of device for continuously preparing nitrite, as figure 2 As shown, the bipolar membrane electrodialyzer 1 is included, the inlet of the bipolar membrane electrodialyzer 1 is connected with the water tank 2 and the inorganic salt solution storage tank 3 respectively, and the outlet of the bipolar membrane electrodialyzer 1 is respectively connected with the residual inorganic salt The solution collection tank 4, the alkali solution concentration section 5 and the inorganic acid solution temporary storage tank 6 are connected;

[0037] The residual inorganic salt solution collection tank 4 is connected with the inorganic salt solution storage tank 3 through the inorganic salt solution batching kettle 15;

[0038] The inorganic acid solution temporary storage tank 6 is connected with the esterification reactor 7, and the esterification reactor 7 is also connected with an alcohol high tank 8 and a nitrite solution high tank 9;

[0039] The...

Embodiment 2

[0045] The present embodiment provides a kind of method for continuously preparing methyl nitrite, the method adopts the device among the embodiment 1, combines figure 1 with figure 2, wherein the bipolar membrane electrodialyzer is composed of multiple modules, all the chambers formed by the positive membrane and the negative surface of the bipolar membrane and all the chambers formed by the negative membrane and the positive surface of the bipolar membrane are connected in parallel and have an inlet a; The chambers composed of the membrane and the positive membrane are connected in parallel and have an inlet b; all the chambers composed of the positive membrane and the negative side of the bipolar membrane are connected in parallel and have an outlet a; all the chambers composed of the negative membrane and the positive surface of the bipolar membrane are connected in parallel and have an outlet b; All the chambers composed of the anion and yang membranes are connected in p...

Embodiment 3

[0052] Present embodiment provides a kind of method for continuously preparing ethyl nitrite, as figure 1 As shown, the method specifically includes the following steps:

[0053] Step 1, water and 20% sodium sulfate aqueous solution are pumped into the electrodialyzer from inlet a and inlet b of the bipolar membrane electrodialyzer respectively, and a DC power supply with a voltage of 1.0V is applied to the bipolar membrane electrodialyzer by a DC power supply;

[0054] Step 2, the sodium sulfate solution passes through the intermediate chamber composed of the anion and yang membranes. Under the action of a direct current electric field, the sodium ions pass through the anode membrane to the adjacent chamber formed by the anode membrane and the negative side of the bipolar membrane, and are separated from the middle chamber of the bipolar membrane. water split (OH — ) ions generate NaOH together, while the anion SO 4 — Go through the negative membrane to the adjacent chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com