A kind of composite filler of biological aerated filter and its application

A technology of biological aerated filter and combined packing, which is applied in the field of water treatment, can solve the problems of long film-hanging time, collapse of packing column, high price, etc., and achieve the effects of fast film-hanging speed, strong supporting effect and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The walnut shell and zeolite are mixed in a volume ratio of 3:1 and applied to the biological aerated filter.

[0037] 1. The start-up and operation effect of the biological aerated filter with membrane

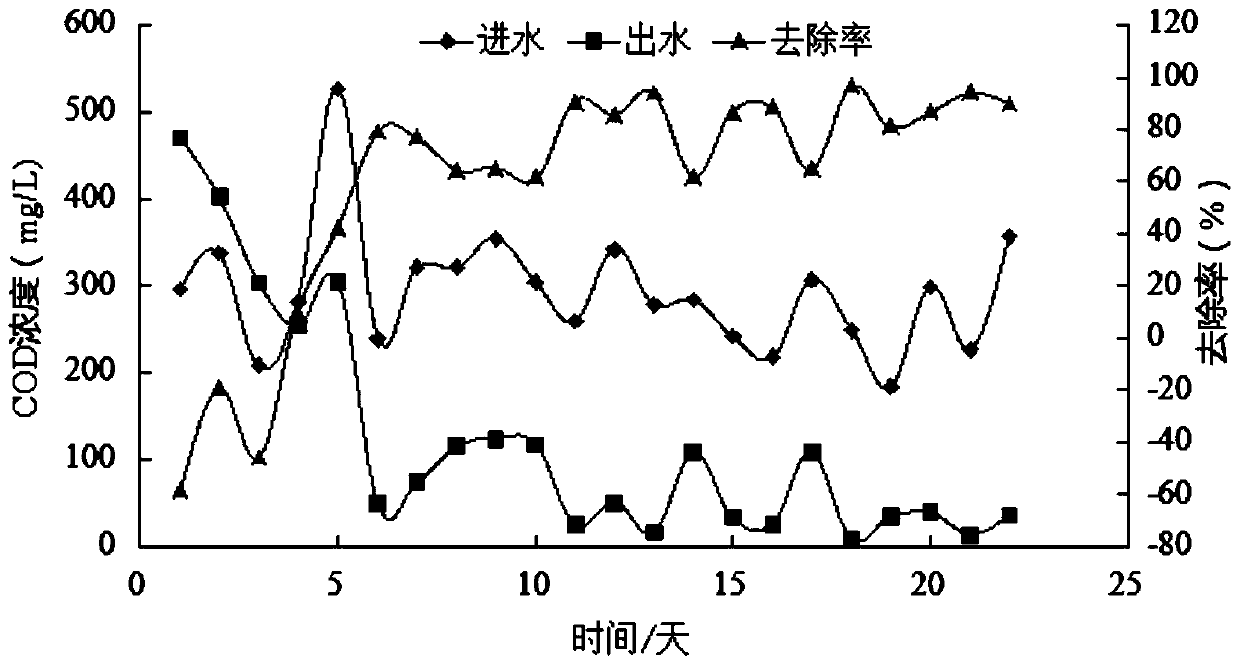

[0038] (1) COD concentration and its removal rate during the start-up of film formation

[0039] From figure 1It can be seen from the figure that the COD removal rate of the biological aerated filter is about 60% at the initial stage of continuous water inflow during the start-up period of the film hanging, and when the continuous reaction reaches the fifth day, the COD removal rate rapidly increases from 61.5% of the previous day to 90%. When the influent organic matter concentration (COD) was in the range of 218.4mg / L-353.9mg / L, COD maintained a high removal rate (61.5%-94%). It can also be seen that, except for the special circumstances of a few days, the COD removal rate generally increases with time, and in the late start-up period, even if the influent COD con...

Embodiment 2

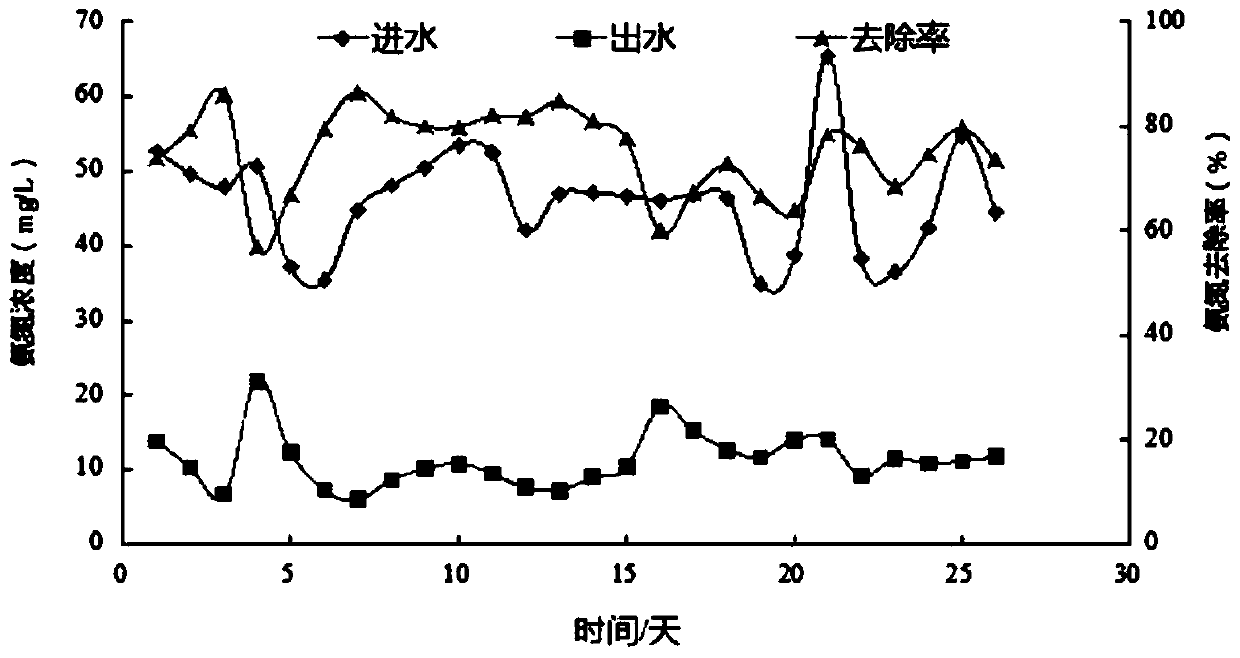

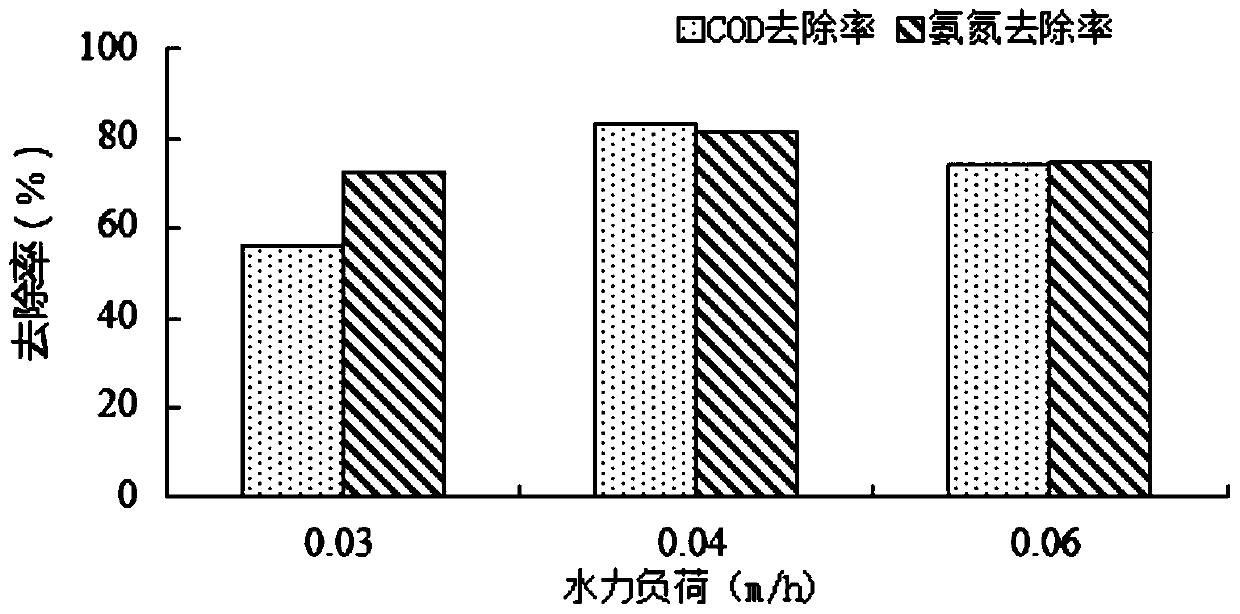

[0056] Mix walnut shells and zeolite in a volume ratio of 2:1 as the filler of the biological aerated filter, and start operation in the same manner as in Example 1. The monitoring results show that it takes 23 days for the biological aerated filter to successfully form a membrane at this time, and the COD and NH 4 + The removal rates of -N were 73.3%-87.5% and 63.2%-77.4%, respectively.

Embodiment 3

[0058] Walnut shells and zeolite are mixed evenly as the biological aerated filter filler in a volume ratio of 4:1, and start operation in the same manner as in Example 1. The monitoring results show that it takes 27 days for the biological aerated filter to successfully form a film at this time. COD and NH 4 + The removal rates of -N can reach 71.8%-89.6% and 65.1%-80.6%, respectively.

[0059] The biological aerated filter composite filler of the present invention, compared with other fillers, has a fast film-hanging speed under the same conditions, and only needs more than 20 days for film-hanging success; 4 + -N) good removal effect,

[0060] In addition, the filler is common agricultural waste with wide sources and low price, and is suitable for mass use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com