Method for preparing sintered neodymium iron boron through grain boundary diffusion of heavy rare earth

A technology of grain boundary diffusion and neodymium iron boron, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of inability to fully exert the effect of heavy rare earth, limited permanent magnet effect, poor squareness, etc., and achieve the best use effect and Convenience, improving utilization efficiency, and avoiding the effect of unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

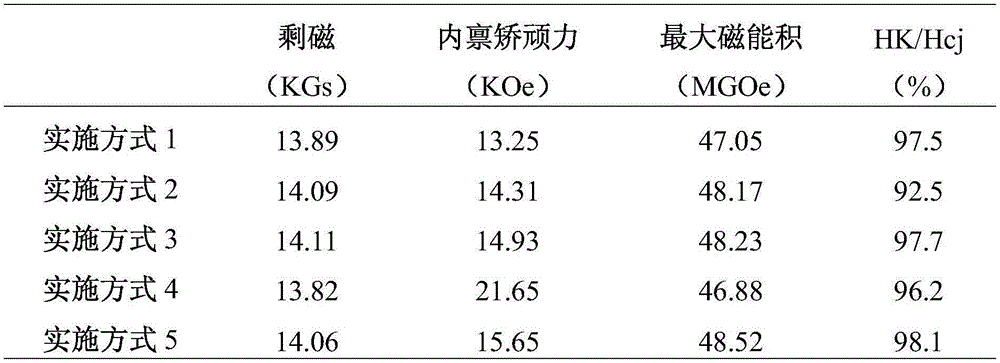

Embodiment approach 1

[0021] Dy is added when the NdFeB alloy is smelted, wherein the amount of Dy accounts for 0.5% of the mass fraction of the NdFeB alloy amount; then it is pressed and formed in a magnetic field press, sintered and aged in a vacuum sintering furnace, wherein the The sintering temperature of vacuum sintering is 1065°C, and the sintering time is 4h. The aging is divided into two times, the first aging is held at 920°C for 5h, and the second aging is held at 470°C for 4h.

Embodiment approach 2

[0023] Mix the iron neodymium boron alloy powder and Dy fluoride in a powder mixer for 30 minutes, wherein the amount of Dy fluoride accounts for 0.5% of the mass fraction of the neodymium iron boron alloy; then press molding in a magnetic field press, and sinter in vacuum Furnace sintering and aging, wherein, the sintering temperature of the vacuum sintering is 1065°C, the sintering time is 4h, the aging is divided into two times, the first aging is kept at 920°C for 5h, and the second aging is at 470°C Keep warm for 4h.

Embodiment approach 3

[0025] A method for preparing sintered NdFeB by diffusing heavy rare earth in the grain boundary, mixing the heavy rare earth material with an organic solvent to form a suspension, and dispersing it into NdFeB alloy powder to obtain NdFeB powder a, which is heated and cooled , After sieving, press molding, sintering and aging treatment.

[0026] Wherein, the preparation method of the suspension is as follows: first transfer 100 parts by weight of the rare earth material and 5 parts by weight of ethanol to a ball mill for ball milling to make a jelly, the ball milling time is 2 hours, take it out and add 80 parts by weight of ethanol, Stir for 3 hours to obtain the suspension; wherein, the heavy rare earth substance is the fluoride of Dy; after mixing the heavy rare earth substance with an organic solvent, put it into a ball mill for grinding, then add an organic solvent again and stir to make a heavy rare earth suspension The turbid liquid is turned into an atomized substance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com