Microsphere intelligent heat-insulated window membrane and preparation method therefor

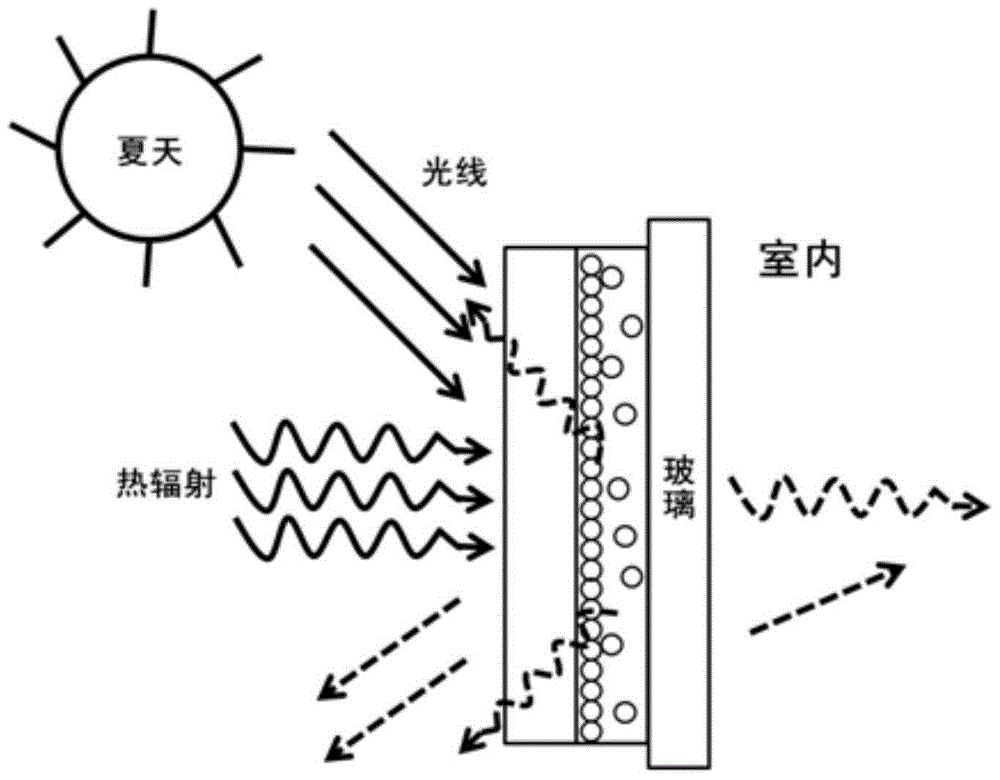

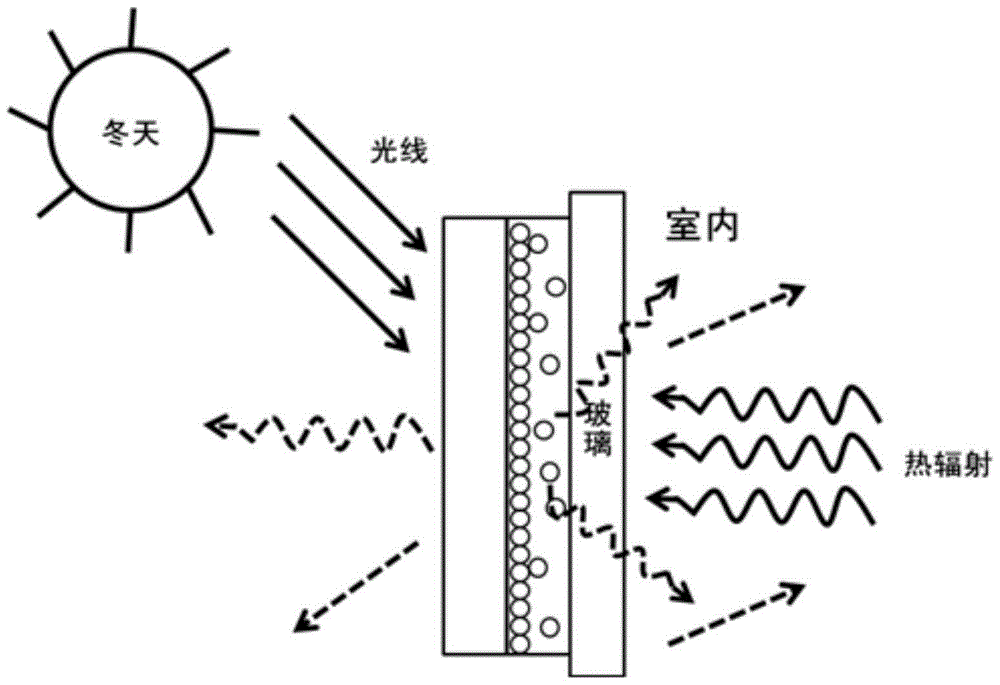

An intelligent thermal insulation and microsphere technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor use effect, pollution, high product cost, reduce air conditioning energy consumption, avoid pollution and damage, heat The effect of radiation protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of heat-insulating nanospheres:

[0025] Dry tungsten-containing vanadium dioxide particles with a particle size of 50 nm at 105°C for 12 hours, add 10 parts of dried tungsten-containing vanadium dioxide nanoparticles into the reaction kettle, add 100 parts of toluene and 5 parts of vinyl trimethyl Oxysilane. Reflux and stir at 100° C. for 4 hours, cool, filter, and dry to obtain nano vanadium dioxide particles with vinyl groups attached to the surface.

[0026] 1 part of nano vanadium dioxide particles with vinyl groups attached to the surface, 300 parts of deionized water, 5 parts of sodium lauryl sulfate (as emulsifier) and 1 part of n-amyl alcohol (as co-emulsifier) were added while stirring ) was pre-emulsified at 80°C for 0.5h. A 1:1 mixed solution of 30 parts of monomer styrene and trimethylolpropane trimethacrylate (as a crosslinking agent) was added dropwise to the reaction kettle at a constant rate within 2 hours, and 0.2 parts of ammonium pe...

Embodiment 2

[0032] Preparation of heat-insulating nanospheres:

[0033] Dry titanium-containing vanadium dioxide particles with a particle size of 400 nm at 105°C for 12 hours, add 50 parts of dried titanium-containing vanadium dioxide nanoparticles to the reaction kettle, add 1000 parts of ethanol and 50 parts of methacrylic acid Acyloxypropyltrimethoxysilane. Reflux and stir at 70° C. for 4 hours, cool and filter, and then dry to obtain nano vanadium dioxide particles with vinyl groups attached to the surface.

[0034] 5 parts of nano-vanadium dioxide particles with vinyl groups attached to the surface, 300 parts of deionized water, 10 parts of sodium lauryl sulfate and 1 part of n-pentanol were added while stirring, and pre-emulsified at 80 ° C for 0.5 h. Add 100 parts of a 1:1 mixed solution of monomer methyl methacrylate and trimethylolpropane trimethacrylate dropwise into the reactor within 2 hours, and at the same time add 50 parts of ammonium persulfate containing 1 part The aqueo...

Embodiment 3

[0040] Preparation of heat-insulating nanospheres:

[0041] Dry zirconium-containing vanadium dioxide particles with a particle size of 200 nm at 105°C for 12 hours, add 20 parts of dried zirconium-containing vanadium dioxide nanoparticles into the reaction kettle, add 500 parts of ethyl acetate and 10 parts of ethylene Triethoxysilane. Reflux and stir at 70° C. for 4 hours, cool and filter, and then dry to obtain nano vanadium dioxide particles with vinyl groups attached to the surface.

[0042] 10 parts of nano-vanadium dioxide particles with vinyl groups attached to the surface, 1000 parts of deionized water, 30 parts of sodium lauryl sulfate and 10 parts of n-amyl alcohol were added while stirring, and pre-emulsified at 80°C for 0.5h. Add 80 parts of a 1:1 mixed solution of n-butyl acrylate monomer and trimethylolpropane trimethacrylate to the reaction kettle dropwise at a constant rate within 2 hours, and at the same time add 50 parts of an aqueous solution containing 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com