Method for using load type platinum catalyst for preparing perfluoroalkyl group ethyl silane and method for preparing load type platinum catalyst

A technology of perfluoroalkylethylsilane and perfluoroalkylethylene is applied in the field of preparing the supported platinum catalyst, which can solve the problems that the catalyst cannot be reused and the reaction yield is high, and achieve good waterproofness, high reaction yield, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

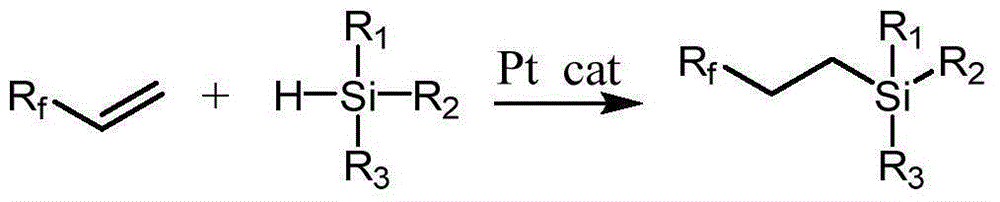

Method used

Image

Examples

Embodiment 1

[0054] Add 446g of heptadecafluorooctylethylene in a 1L three-necked flask, and then add 1.2g (10ppm) of silica gel-supported platinum catalyst. The platinum loading in the silica gel-supported platinum catalyst is 0.5%. 135g of trichlorosilane was added dropwise for 1 hour, then stored at temperature for 5 hours, filtered to obtain a filter residue as a supported platinum catalyst after the reaction was completed, and finally the crude product filtrate was subjected to rectification treatment, and finally 523g of the product perfluorodecyltrichlorosilane was obtained, Yield 96.5%.

Embodiment 2~15

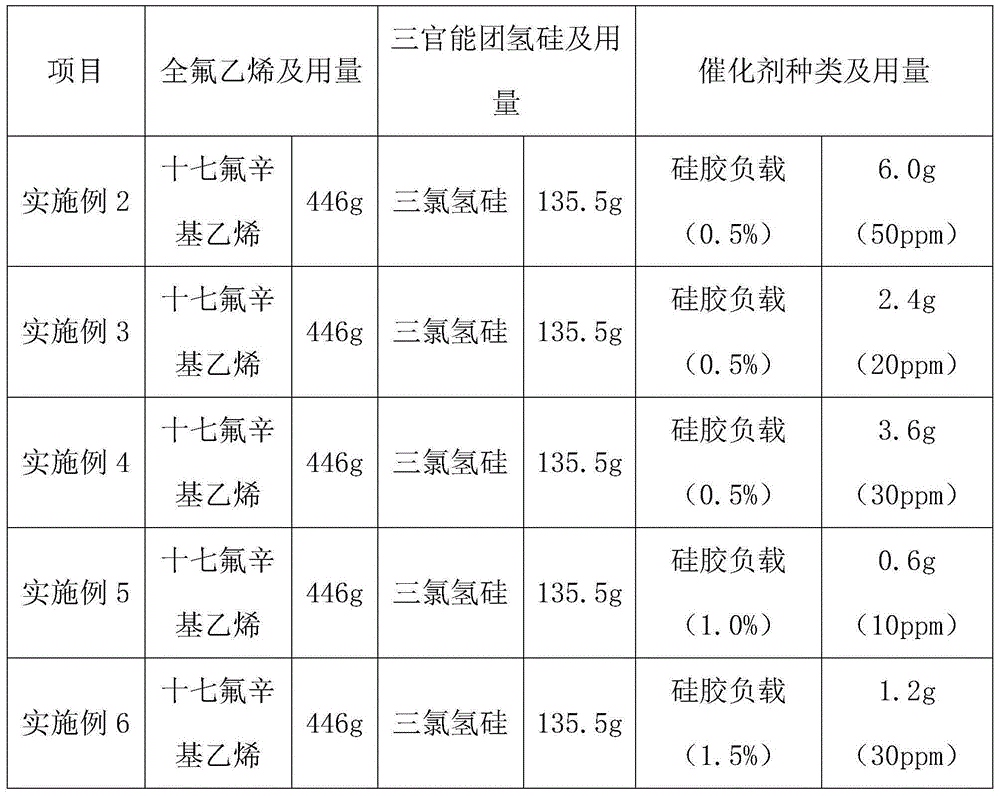

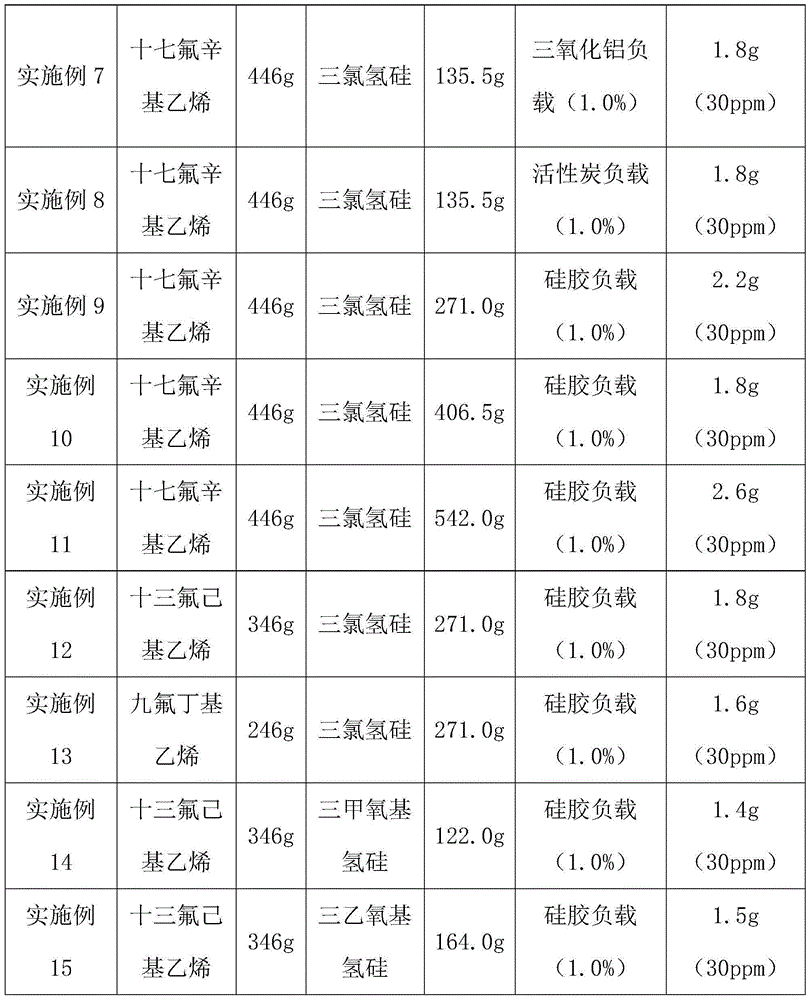

[0056] Using the same synthesis steps as in Example 1, see Table 1 for the specific formula, and see Table 2 for the specific process conditions and product yield.

[0057] Table 1

[0058]

[0059]

[0060] Table 2

[0061] project

Reaction temperature (°C)

Reaction time (h)

yield

[0062] Example 2

75

5

97.1%

Example 3

85

5

97.3%

Example 4

95

5

97.3%

Example 5

110

5

97.1%

Example 6

120

5

97.6%

Example 7

85

1

97.9%

Example 8

85

3

98.3%

Example 9

85

4

97.3%

Example 10

85

6

98.1%

Example 11

85

8

98.6%

Example 12

90

5

98.3%

Example 13

85

6

98.3%

Example 14

100

5

98.5%

Example 15

85

6

97.2%

[0063] According to the same formulation and process conditions as in Examples 1, 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com