Mn and Nb added NiCrFe alloy surfacing solder strip for nuclear power and welding method

A welding method and alloy technology, which is applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problem that it cannot fully meet the welding requirements of steam generator tube sheets, stress corrosion cracks and other micro cracks are difficult to control and cannot meet Technical index requirements and other issues, to achieve the effect of excellent metal mechanical properties, excellent corrosion resistance, and comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following examples describe the present invention in more detail.

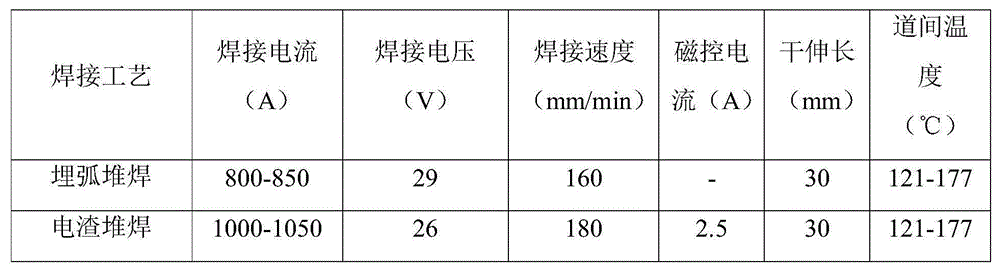

[0040] According to the chemical composition of the welding strip provided in Table 1, the raw materials are selected, and the steel strip is made into a steel strip through smelting-casting-forging-rolling-hot-rolling-picking-cold rolling-slitting and coiling. The specification is 0.5mm thick and 60mm wide. The band is labeled HD1. The submerged arc process and the electroslag process were used to weld on the 40mm thick SA508-III steel.

[0041] (1) Strip submerged arc surfacing: choose HD1, welding current 800-850A, welding voltage 29V, welding speed 160mm / min;

[0042] (2) Strip electroslag surfacing: choose HD1, welding current 1000-1050A, magnetron current 2.5A, welding voltage 26V, welding speed 180mm / min;

[0043] (3) The welding manufacturability of submerged arc surfacing and electroslag surfacing were recorded respectively, and evaluated, and the chemical composition and mechanical prope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com