Preparation method of cobalt-cerium composite oxide catalyst and cobalt-cerium composite oxide catalyst

A technology of composite oxides and catalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of large catalyst particles, cumbersome catalysts, and difficult control , to achieve the effect of simplifying the process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

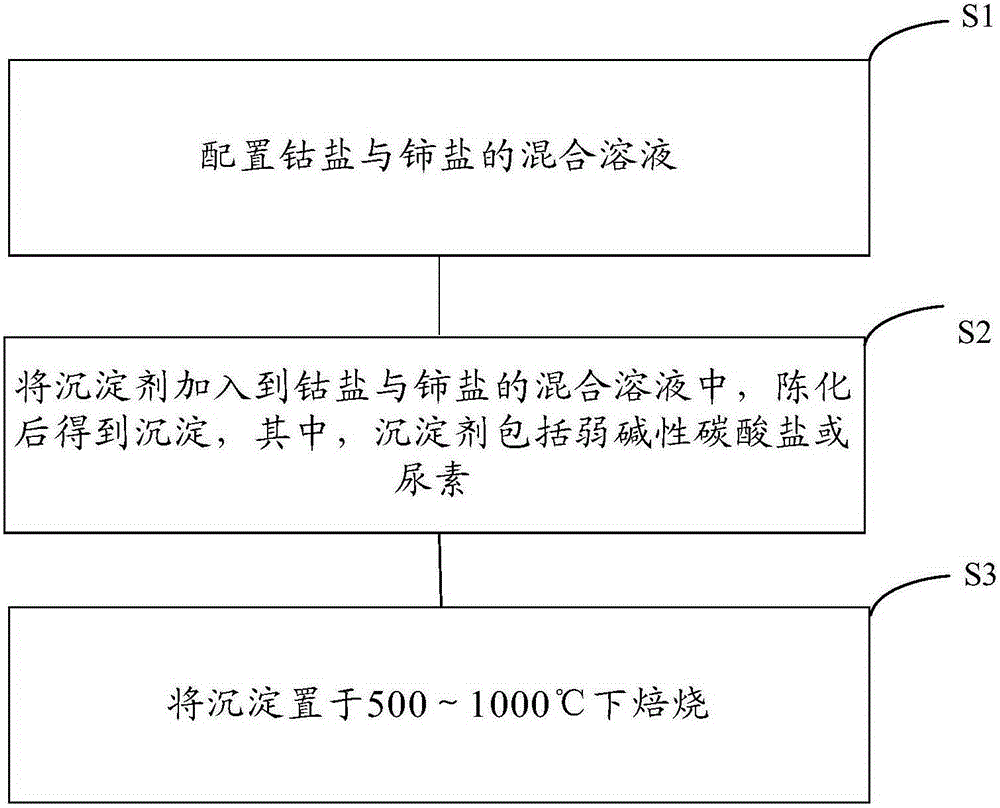

[0024] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing a cobalt-cerium composite oxide catalyst, which may specifically include the following steps:

[0025] S1, configure the mixed solution of cobalt salt and cerium salt;

[0026] S2, adding a precipitating agent into the mixed solution of cobalt salt and cerium salt, and obtaining precipitation after aging, wherein the precipitating agent is weakly alkaline carbonate or urea;

[0027] S3. Calcining the precipitate obtained in step S1 at 500-1000°C.

[0028] The embodiment of the present invention provides a preparation method of a cobalt-cerium composite oxide catalyst. The co-precipitation method is used to co-precipitate the cobalt salt and the cerium salt with weakly alkaline carbonate or urea, and then the Roasting is carried out under the present co-precipitation method due to the use of sodium hydroxide or potassium hydroxide and need to accurately control multiple f...

Embodiment 1

[0068] Embodiment 1: Preparation of cobalt-cerium composite oxide catalyst with cobalt-cerium molar ratio of 1:1:

[0069] (1) Add 17.46g cobalt nitrate hexahydrate, 26.04g cerium nitrate hexahydrate into the beaker, stir and dissolve in 200ml distilled water;

[0070] (2) Get 23.7g ammonium bicarbonate in another beaker, stir and dissolve in 200ml water;

[0071] (3) drop the precipitating agent solution prepared in step (2) into the aqueous solution prepared in step (1) at room temperature, and age for 3 hours after dropping;

[0072] (4) Suction filter the precipitate obtained in step (3), wash the precipitate 3 times with 500ml of water, then drain it, and dry it at 110°C for 5h;

[0073] (5) Crush the dried precipitate in step (4), heat up to 700° C. at 4° C. / min in a muffle furnace, heat-preserve and roast for 4 hours, and cool to obtain catalyst powder.

Embodiment 2

[0074] Embodiment 2: the cobalt cerium composite oxide catalyst that preparation cobalt cerium molar ratio is 3:1:

[0075] (1) Add 26.19g cobalt nitrate hexahydrate, 13.02g cerium nitrate hexahydrate into the beaker, stir and dissolve in 200ml distilled water;

[0076] (2) Get 21.3g ammonium bicarbonate in another beaker, stir and dissolve in 200ml water;

[0077] (3) drop the precipitating agent solution prepared in step (2) into the aqueous solution prepared in step (1) at room temperature, and age for 3 hours after dropping;

[0078] (4) Suction filter the precipitate obtained in step (3), wash the precipitate 3 times with 500ml of water, then drain it, and dry it at 110°C for 5h;

[0079] (5) Crush the dried precipitate in step (4), heat up to 700° C. at 4° C. / min in a muffle furnace, heat-preserve and roast for 4 hours, and cool to obtain catalyst powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com