Oral prosthetic bracket manufacturing method and prosthetic bracket manufactured by metal additive

A metal additive and dental technology, applied in prostheses, bone implants, medical science, etc., can solve the problems of multiple processes, reduce the forming accuracy of removable partial denture brackets, and high manufacturing costs, and achieve complex structures and save manpower , The effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 The method for manufacturing an oral prosthesis bracket manufactured by metal additives according to the present invention comprises the following steps:

[0040] 1) Obtain the 3D model data of the patient's oral cavity and upper jaw: take the mold from the patient's mouth and make a plaster cast of the oral cavity, and obtain the 3D point cloud data of the plaster cast by scanning the plaster cast of the oral cavity with a scanning device, or directly scan the patient's mouth with a scanning device to obtain directly The 3D point cloud data of the patient's oral cavity, and the 3D point cloud data is exported to the triangular mesh model through the scanning software;

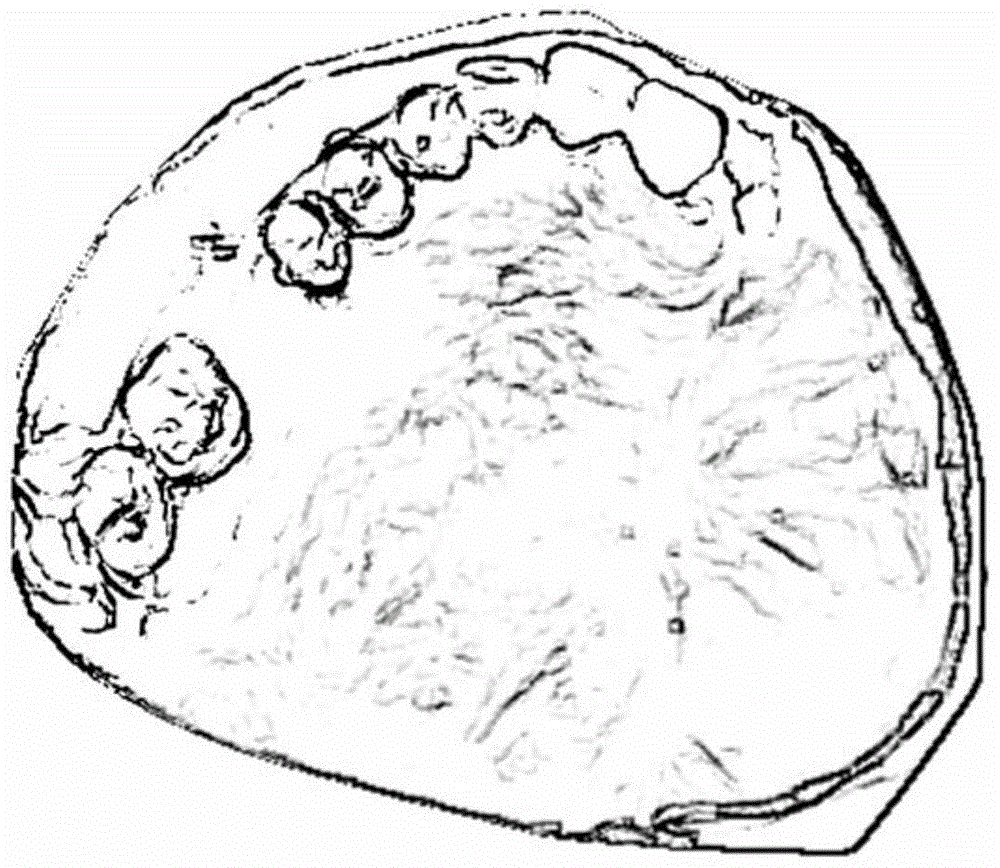

[0041] 2) Select the maxillary surface of the oral prosthesis bracket on the model: import the triangular mesh data in step 1) into the reverse engineering software Geomagic, and select the tissue surface base of the oral prosthetic bracket on the triangular mesh model surface, and generate...

Embodiment 2

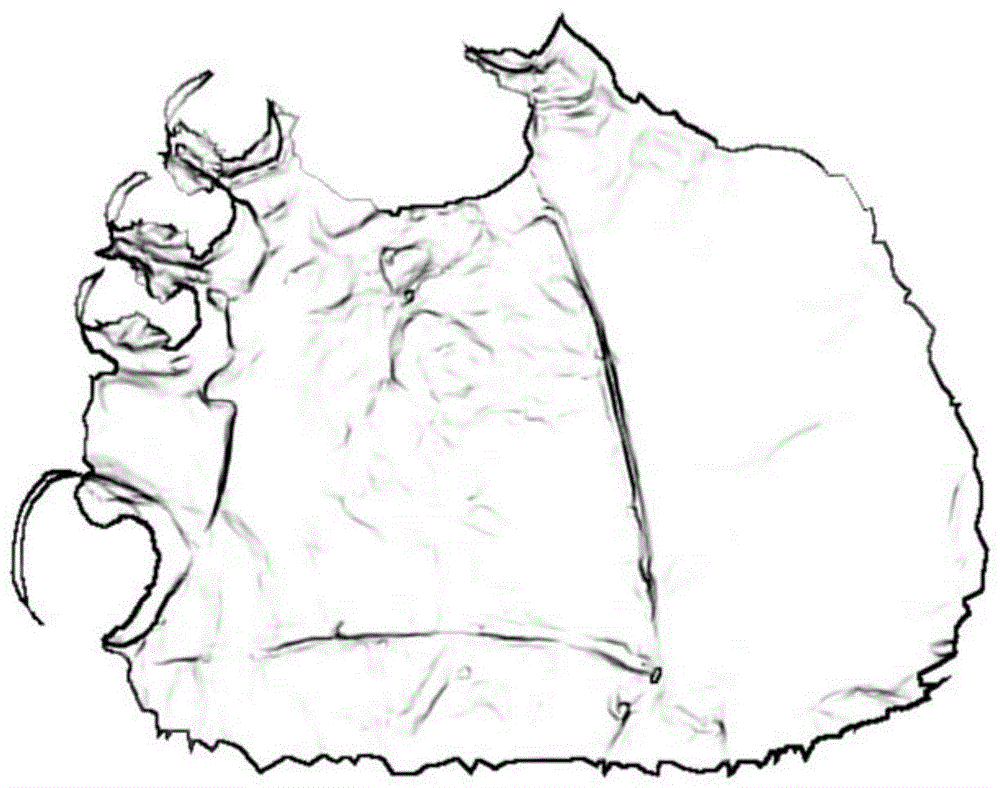

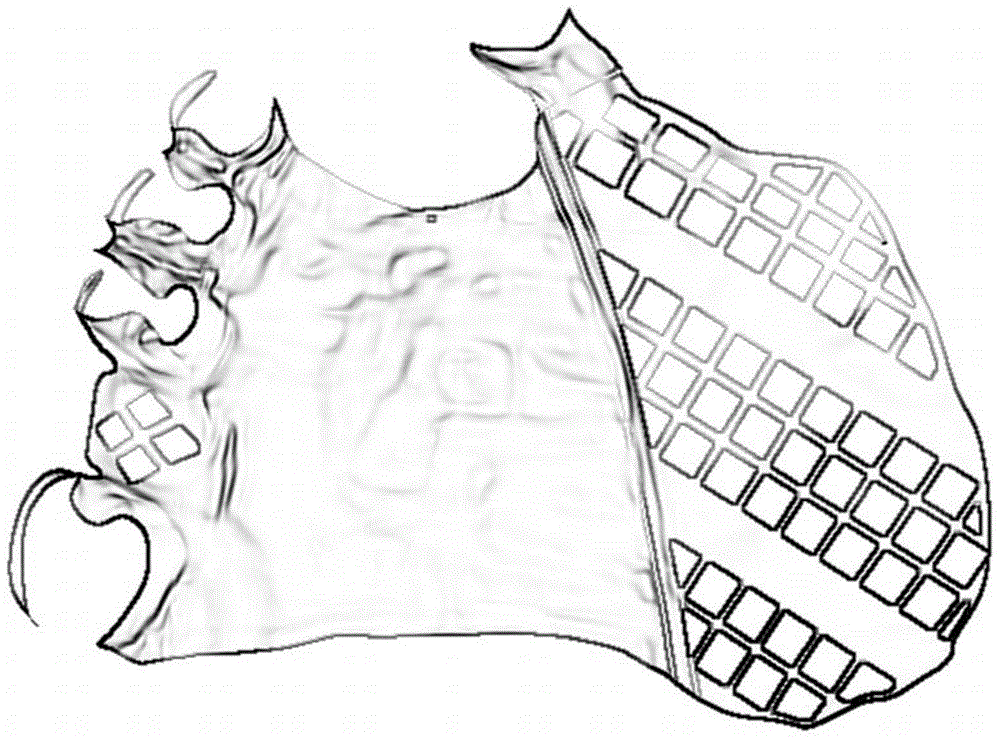

[0048] Example 2 The dental prosthesis bracket made according to the manufacturing method described in Example 1 includes a body made of metal material, and the body includes a sleeve part 1 and a support part 2 with a mesh structure, so The said fitting part 1 is arranged on the edge of one side of the said supporting part 2, the said mesh structure 21 is located on the other side of said supporting part 2, and said fitting part 1 and said The support part 2 is integrally formed; the support part 2 fully fits the patient's defective oral and maxillofacial region and provides the supporting force required to resist the physiological movement of the oral and maxillofacial region, and the fitting part 1 is set on the patient's partial dentition, Moreover, the said fitting part 1 has a shape for providing the supporting force required for tooth movement.

[0049] The metal material is stainless steel, pure titanium, titanium alloy, cobalt-chromium alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com