A preparation method of zinc germanate/carbon composite fiber negative electrode material for lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, spinning solution preparation, circuits, etc., can solve the problems of reducing the actual specific capacity of electrode materials, low electrical conductivity and ion mobility, and difficult maintenance of electrode structures. Facilitate large-scale application, improve electrical conductivity, and enrich the effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

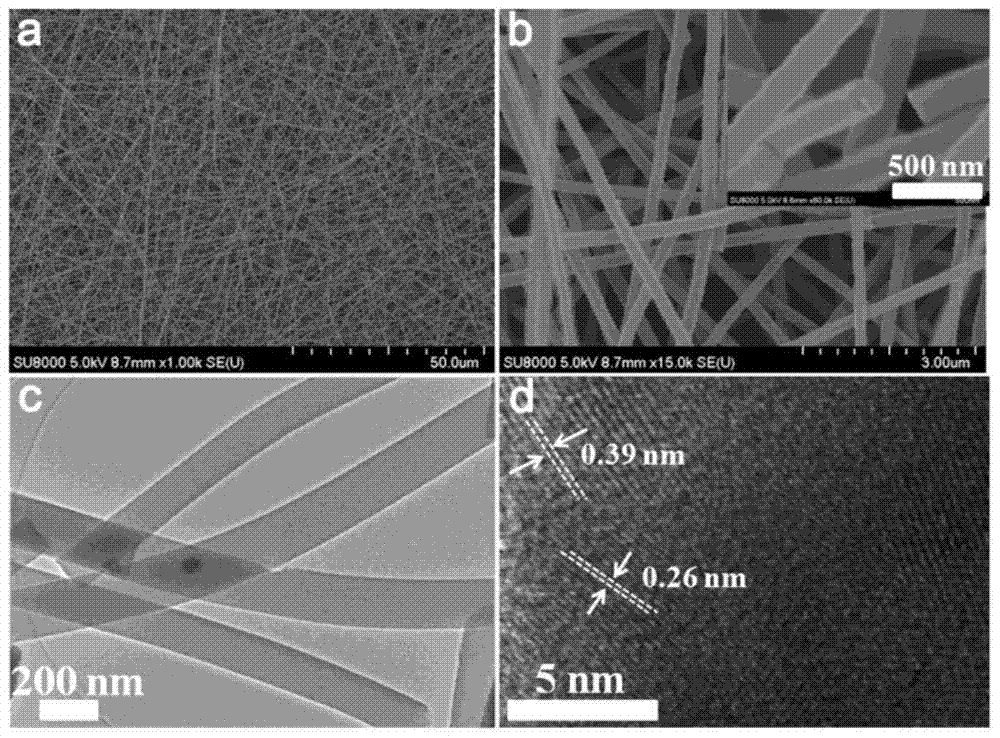

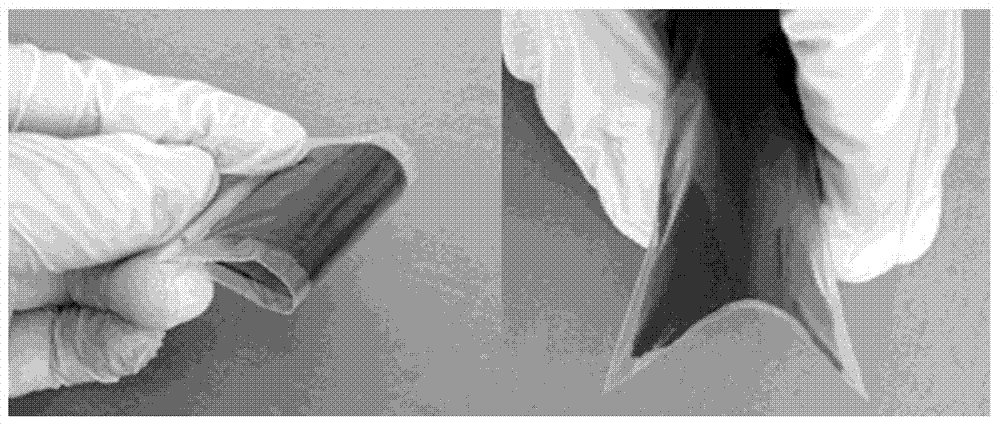

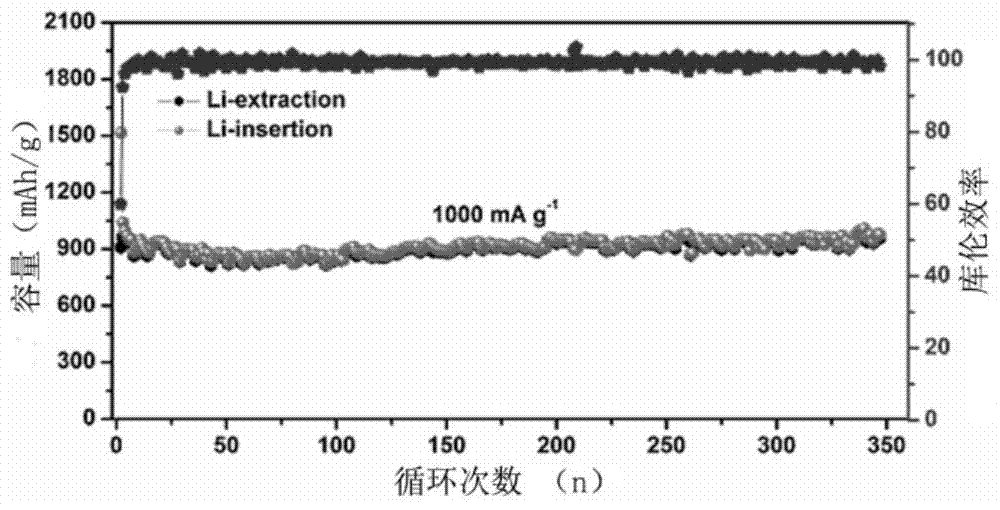

Embodiment 1

[0027] Dissolve 8g of PAA in 100mL of water, and combine magnetic stirring and ultrasonic vibration to fully dissolve PAA. Disperse 1g of zinc germanate in 25mL of the above PAA aqueous solution and mix well; then add citric acid under stirring and stir for 1 hour to obtain a uniform and transparent spinning solution. Then, under the voltage of 13kV, the prepared solution was electrospun; after the spinning was completed, the spinning was collected, and the tube furnace was heat-treated at 700°C for 5 hours under the protection of nitrogen, and finally a self-supporting structure was obtained. Zn2 GeO 4 / C composite fiber. Prepared Zn 2 GeO 4 The single fiber diameter of / C composite fiber is about 180nm, and the length is hundreds of microns, which has good mechanical flexibility. at 1A g -1 Under the current density, the capacity remains at 912.5mAh g after 300 cycles -1 above and the Coulombic efficiency is higher than 99%.

Embodiment 2

[0029] Dissolve 8g of PAA in 100mL of water, and combine magnetic stirring and ultrasonic vibration to fully dissolve PAA. Disperse 0.7g of zinc germanate in 25mL of the above PAA aqueous solution and mix well; then add citric acid under stirring and stir for 1 hour to obtain a uniform and transparent spinning solution. Then, under the voltage of 15kV, the prepared solution was electrospun; after the spinning was completed, the spinning was collected, and the tube furnace was heat-treated at 700°C for 5 hours under the protection of nitrogen, and finally a self-supporting structure was obtained. Zn 2 GeO 4 / C composite fiber. at 1A g -1 Under the current density, the capacity remains at 916.7mAh g after 300 cycles -1 above and the Coulombic efficiency is higher than 99%.

Embodiment 3

[0031] Dissolve 8g of PAA in 100mL of water, and combine magnetic stirring and ultrasonic vibration to fully dissolve PAA. Disperse 1.5g of zinc germanate in 30mL of the above PAA aqueous solution and mix well; then add citric acid under stirring and stir for 1 hour to obtain a uniform and transparent spinning solution. Then, under the voltage of 12kV, the prepared solution was electrospun; after the spinning was completed, the spinning was collected, and the tube furnace was heat-treated at 750°C for 5 hours under the protection of nitrogen, and finally a self-supporting structure was obtained. Zn2GeO4 / C composite fiber. at 1A g -1 Under the current density, the capacity remains at 726.6mAh g after 300 cycles -1 above and the Coulombic efficiency is higher than 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com