Continuous long carbon fiber reinforced thermoplastic nanocomposite and preparation method and application thereof

A technology of nano-composite materials and reinforced thermoplastic, which is applied in the field of long carbon fiber thermoplastic resin-based composite materials, can solve the problems of not being able to meet the requirements of batch production, low cost, poor low-temperature impact resistance, and high manufacturing and processing costs, and achieves UV resistance. Aging, low temperature impact resistance, good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

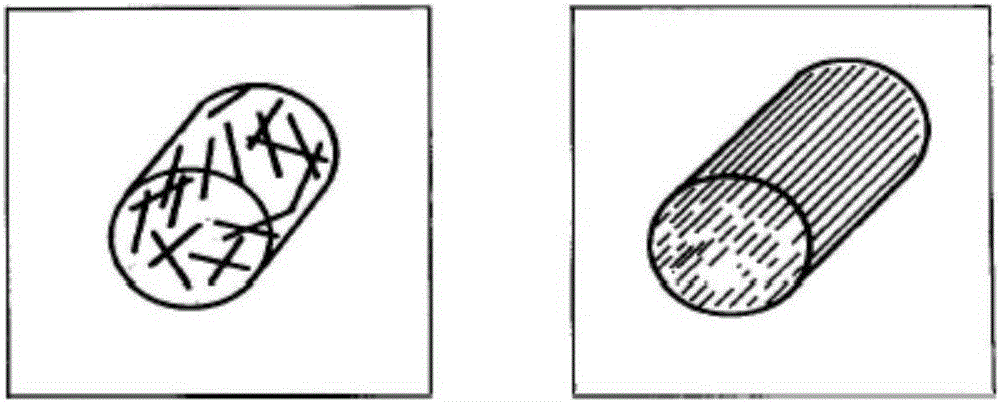

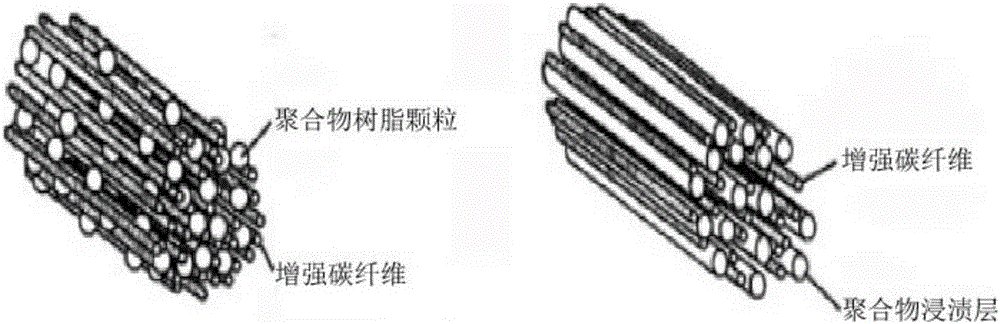

[0020] The present invention provides a method for preparing continuous long carbon fiber reinforced thermoplastic resin-based nanocomposites (LCFRT), comprising the following steps: using precision sensors (viscosity, temperature and pressure) to control continuous carbon fiber bundles (CCF) and low-viscosity molten thermoplastic The resin blend is heated at temperature, pressurized pressure, and traction tension, and 11-15 rolling rollers with different chamfering angles are installed inside the extrusion and dipping groove mold to form a continuous long-distance carbon fiber (bundle) arrangement. Monofilament carbon fiber (CCF), and while maintaining the melting temperature and low-viscosity fluid, the effective isostatic pressure in the dipping tank is controlled at the same time: 85-250MPa, so that the continuous monofilament carbon fiber (CCF) can be completely impregnated with hot melt , Wetting and compacting forming composite (process), the interface strength between t...

Embodiment 1

[0028] Preparation of long carbon fiber reinforced PA66 nanocomposites (granules, LFT-PA66-LCF40): the proportion of the total weight of each component is: 40wt% PA66, 3wt% maleic anhydride grafted POE (compatibilizer), 2wt% conductive carbon black, 2wt% conductive graphite, 0.3wt% carbon nanotube, 0.2wt% polytetrafluoroethylene, 1.5wt% molybdenum disulfide, 1wt% micron aluminum fiber, 0.5wt% nano silicon carbide fiber, 0.5wt% Nano-graphene, 3wt% nano-aluminum nitride, 2wt% nano-molybdenum nitride, 1wt% nano-alumina, 0.5wt% nano-magnesia, 0.5wt% alkyl bis fatty acid amide, 1wt% anti-ultraviolet light agent 745, 1wt% The blend of antioxidant (0.5wt% 1010 and 0.5wt% 164), then on the high-speed mixer, uniformly mix and stir at low speed (35 rpm) and high speed (85 rpm), then you can get Multiphase multicomponent blend composites.

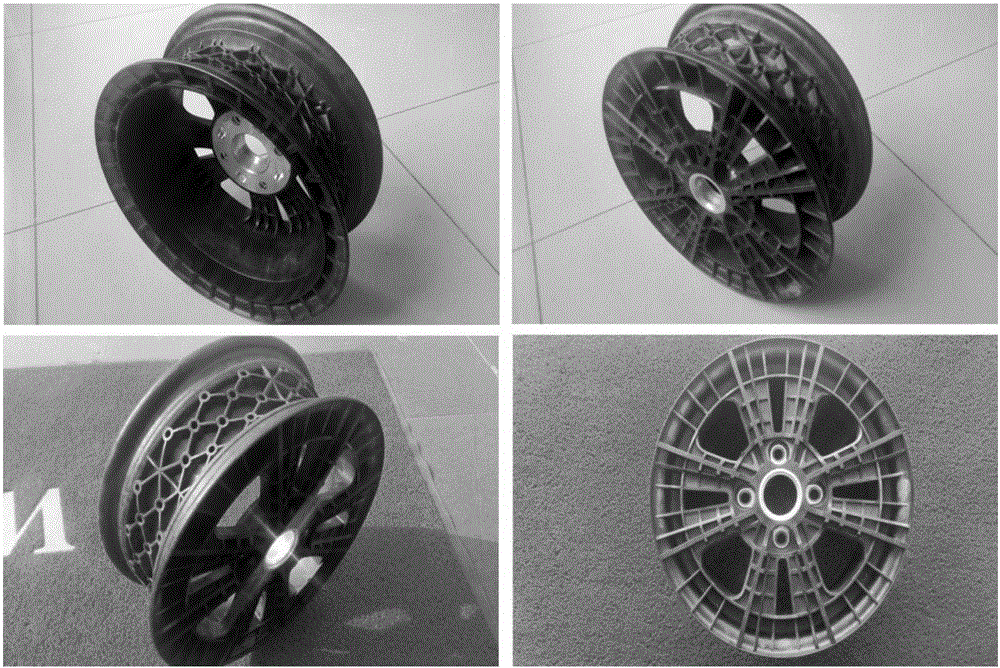

[0029] Using precisely controlled continuous carbon fiber filament yarn (CF, Japan Toray T700, 12K) to blend with the above-mentioned multi-componen...

Embodiment 2

[0037] Preparation of long carbon fiber reinforced PA66 nanocomposites (granules, LFT-PA66-LCF50): the proportion of the total weight of each component is: 28.5wt% PA66, 3wt% maleic anhydride grafted POE (compatibilizer), 2wt% conductive carbon black, 3wt% conductive graphite, 0.3wt% carbon nanotube, 0.3wt% polytetrafluoroethylene, 2wt% molybdenum disulfide, 1wt% micron aluminum fiber, 0.2wt% nano silicon carbide fiber, 0.5wt% nano Graphene, 3wt% nano-aluminum nitride, 2wt% nano-molybdenum nitride, 1wt% nano-alumina, 0.2wt% nano-magnesia, 1wt% alkyl bis fatty acid amide, 1wt% anti-ultraviolet agent 745, 1wt% antioxidant The blend of the agent (0.5wt% 1010 and 0.5wt% 164), first low speed (35 rev / min) and then high speed (125 rev / min), uniformly stirred and mixed in a high-speed mixer, then obtained multiphase poly Component blend compound.

[0038] Special impregnation under heat and pressure on the 45-type twin-screw extruder using precision-controlled continuous carbon fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com