Antibacterial flame-retardant ABS plastic and preparation method thereof

A technology of ABS plastic and manufacturing method, applied in the field of polymer material modification, can solve problems such as inability to provide, and achieve the effects of strong scratch resistance, high gloss and good performance index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The manufacture method of the antibacterial flame-retardant ABS plastic of the present invention comprises the following main steps:

[0040] 1) Air-dry the SAN resin at 100-120°C for 4-6 hours;

[0041] 2) Prepare materials according to the formula quantity, add the dried SAN resin, composite environmental protection flame retardant, toughening agent, composite antibacterial agent, anti-scratch agent, antioxidant and compatibilizer into the mixer in sequence, and turn it at 300-500 rpm Stir at a high speed of 100-200 rpm for 3-5 minutes, then add ABS high-gloss masterbatch, and stir at a low speed of 100-200 rpm for 1-3 minutes to obtain a preliminary mixture;

[0042] 3) Add the preliminary mixture into an extruder, melt, extrude, granulate, water-cool, air-dry, pelletize, and dry.

[0043] In addition, the processing conditions of the extruder are as follows:

[0044] Temperature: Zone 1 160-180℃, Zone 2 170-190℃, Zone 3 200-220℃, Zone 4 200-220℃, Zone 5 190-220℃, ...

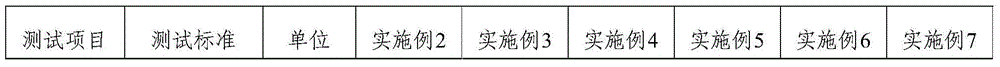

Embodiment 2-7

[0047] An antibacterial and flame-retardant ABS plastic is manufactured by the method of Example 1 from the following raw materials in parts by weight: 100 parts of SAN resin, 5-30 parts of composite environmental protection flame retardant, 18 parts of toughening agent, 1.9 parts of composite Type antibacterial agent, 3.4 parts of ABS high-gloss masterbatch, 2.5 parts of anti-scratch agent, 0.5 part of antioxidant and 3 parts of compatibilizer, as shown in Table 1.

[0048] Among them, the composite environment-friendly flame retardant consists of the following components by weight: 15 parts of dimethyl trimethylsilyl phosphonate, 38 parts of melamine cyanurate, 16 parts of zinc borate, and 50 parts of magnesium hydroxide.

[0049] The toughening agent is composed of the following components by weight: 1 part of methyl methacrylate-acrylic acid copolymer (ACR), 1 part of methyl methacrylate-butadiene-styrene terpolymer (MBS). Methyl methacrylate-butadiene-styrene terpolymer (MB...

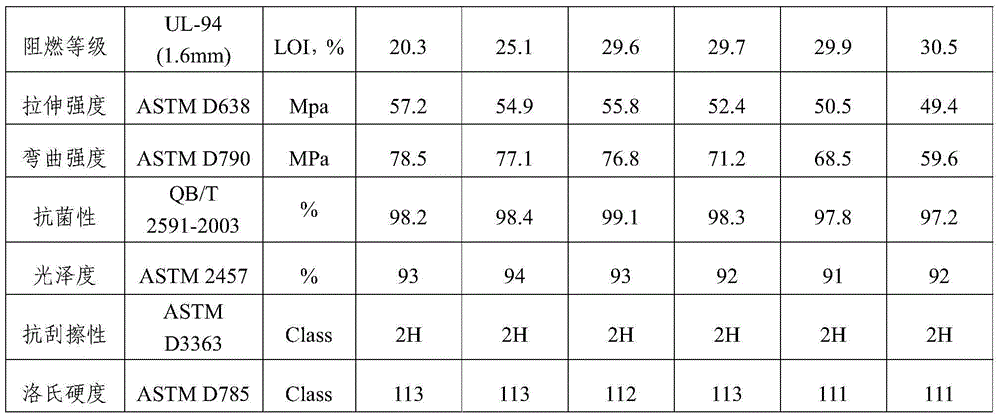

Embodiment 8-13

[0062] An antibacterial and flame-retardant ABS plastic is manufactured according to the method of Example 1 from the following raw materials in parts by weight: 100 parts of SAN resin, 15 parts of composite environmental protection flame retardant, 18 parts of toughening agent, 0.1-3.0 parts of composite Type antibacterial agent, 3.4 parts of ABS high-gloss masterbatch, 2.5 parts of anti-scratch agent, 0.5 parts of antioxidant and 3 parts of compatibilizer, as shown in Table 3.

[0063] Among them, the components of composite environmental protection flame retardant, toughening agent, composite antibacterial agent, anti-scratch agent, antioxidant, ABS high-gloss masterbatch and compatibilizer are the same as those in Examples 2-7.

[0064] The antibacterial flame-retardant ABS plastic formula table (parts by weight) of table 3 embodiment 8-13

[0065]

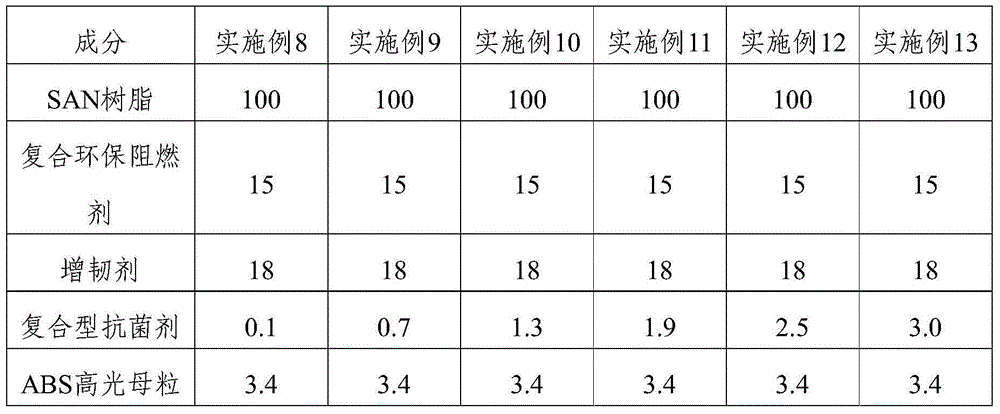

[0066]

[0067] The test result of table 4 embodiment 8-13

[0068]

[0069] Referring to Table 4, according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com