A visible light responsive nb 2 o 5 /g‑c 3 n 4 Preparation method and use of heterojunction material

A heterojunction and visible light technology, applied in chemical instruments and methods, light water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of photocatalytic activity and visible light utilization efficiency, and achieve excellent light Catalytic activity, convenient mass production, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: Weigh 2.5 g of melamine, place it in an agate mortar, and grind it evenly for 5 minutes to obtain sample A.

[0025] Step 2: Weigh 0.025 g of niobium pentoxide and 2.5 g of melamine respectively, place them in an agate mortar, grind and mix them evenly for 5 minutes, and obtain sample B.

[0026] Step 3: Transfer sample A and sample B to a 50 mL round crucible, cover the crucible and place it horizontally in the muffle furnace, set the initial temperature of the muffle furnace to 50 °C, and increase the temperature at a rate of 2.3 °C / min Raise the temperature of the muffle furnace to 550 °C, and react at this temperature for 4 h, and wait for natural cooling to room temperature to obtain samples A 1 and B 1 .

[0027] Step 4: Separate sample A 1 and B 1 Transfer to an agate mortar and grind for 5 min to finally obtain g-C 3 N 4 and Nb 2 o 5 / g -C 3 N 4 heterojunction samples.

Embodiment 2

[0029]Step 1: Weigh 2.5 g of melamine, place it in an agate mortar, and grind it evenly for 5 minutes to obtain sample A.

[0030] Step 2: Weigh 0.075 g of niobium pentoxide and 2.5 g of melamine respectively, place them in an agate mortar, grind and mix them evenly for 5 minutes, and obtain sample B.

[0031] Step 3: Transfer sample A and sample B to a 50 mL round crucible, cover the crucible and place it horizontally in the muffle furnace, set the initial temperature of the muffle furnace to 50 °C, and increase the temperature at a rate of 2.3 °C / min Raise the temperature of the muffle furnace to 550 °C, and react at this temperature for 4 h, and wait for natural cooling to room temperature to obtain samples A 1 and B 1 .

[0032] Step 4: Separate sample A 1 and B 1 Transfer to an agate mortar and grind for 5 min to finally obtain g-C 3 N 4 and Nb 2 o 5 / g -C 3 N 4 heterojunction samples.

Embodiment 3

[0034] Step 1: Weigh 2.5 g of melamine, place it in an agate mortar, and grind it evenly for 5 minutes to obtain sample A.

[0035] Step 2: Weigh 0.125 g of niobium pentoxide and 2.5 g of melamine respectively, place them in an agate mortar, grind and mix evenly for 5 minutes, and obtain sample B.

[0036] Step 3: Transfer sample A and sample B to a 50 mL round crucible, cover the crucible and place it horizontally in the muffle furnace, set the initial temperature of the muffle furnace to 50 °C, and increase the temperature at a rate of 2.3 °C / min Raise the temperature of the muffle furnace to 550 °C, and react at this temperature for 4 h, and wait for natural cooling to room temperature to obtain samples A 1 and B 1 .

[0037] Step 4: Separate sample A 1 and B 1 Transfer to an agate mortar and grind for 5 min to finally obtain g-C 3 N 4 and Nb 2 o 5 / g -C 3 N 4 heterojunction samples.

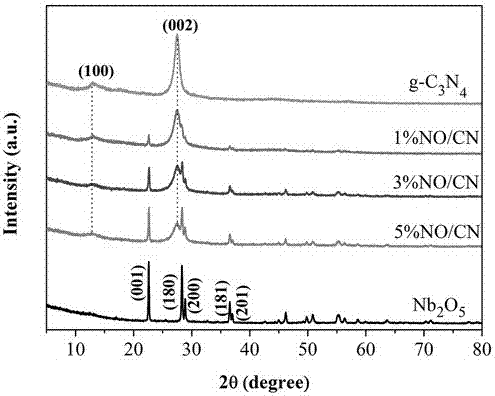

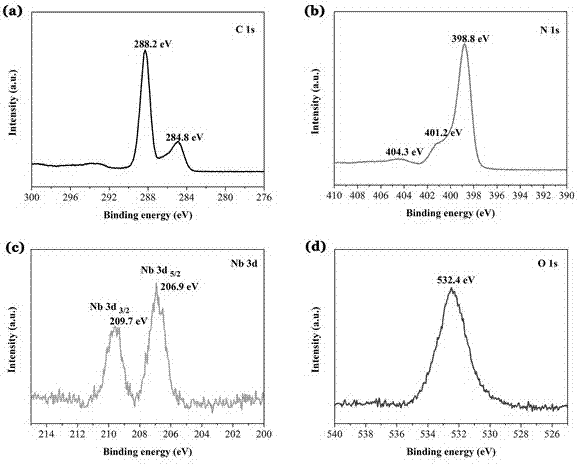

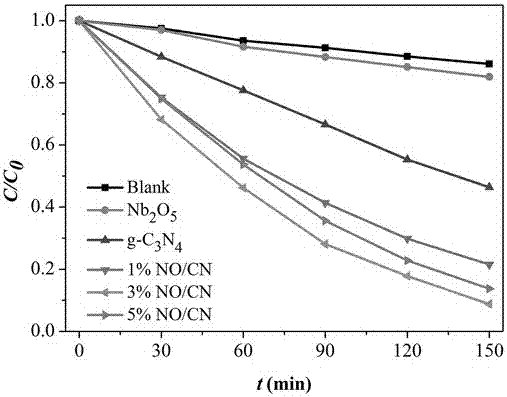

[0038] By adjusting the mass ratio of adding different niobium pentoxide and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com