A kind of cathode material and preparation method thereof

A cathode material, lithium-rich manganese-based technology, applied in the field of lithium-rich manganese-based solid solution cathode material and its preparation, can solve the problems of poor rate performance, large irreversible capacity loss, poor conductivity of lithium-rich manganese-based solid solution, etc., to achieve Effects of Avoiding Direct Contact, Improving Cycle Performance and Rate Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a method for preparing the positive electrode material described in the above technical solution, comprising the following steps:

[0042] (1) dissolving the organic carbon source and ammonium metavanadate in a solvent to obtain a mixed solution;

[0043] (2) dispersing the lithium-rich manganese-based solid solution in the mixed solution obtained in the step (1) to form a suspension;

[0044] (3) removing the solvent in the suspension obtained in the step (2), drying the obtained solid to obtain a positive electrode material precursor;

[0045] (4) heat-treating the positive electrode material precursor obtained in step (3) to obtain the positive electrode material.

[0046] In the invention, the organic carbon source and the ammonium metavanadate are mixed and dissolved in a solvent to obtain a mixed solution. In the present invention, there is no special limitation on the operation of preparing the mixed solution, and the technic...

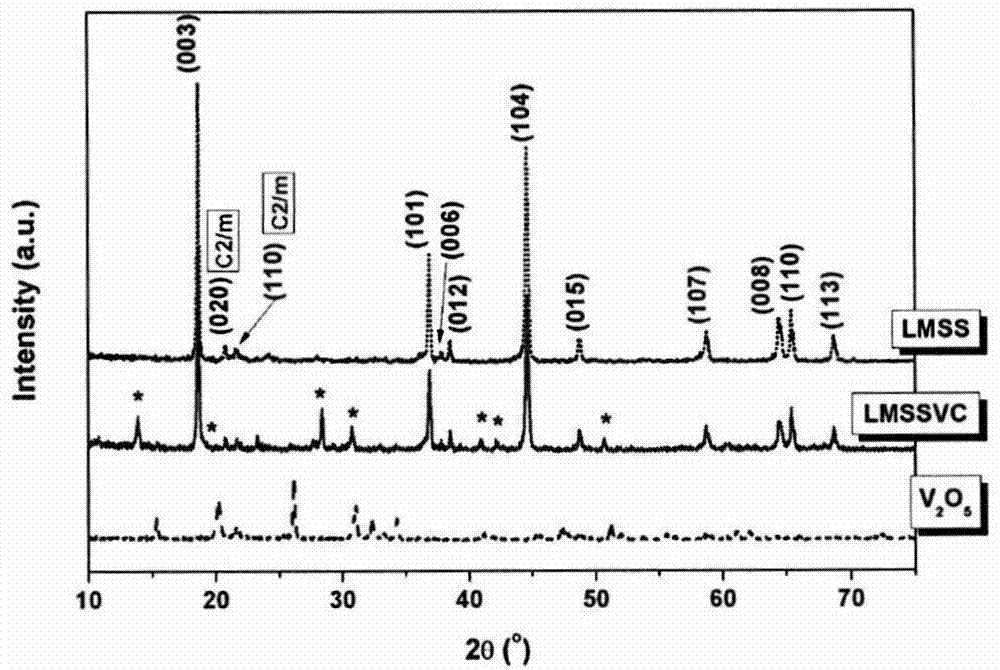

Embodiment 1

[0067] Weigh 19.286g ammonium metavanadate, dissolve 11.875g sucrose in 500ml deionized water, then add 100g lithium-rich manganese-based solid solution 0.5Li 2 MnO 3 0.5Li(Mn 1 / 3 co 1 / 3 Ni 1 / 3 )O 2 , stir evenly; heat in an oil bath at 120°C until the water is evaporated to dryness, transfer to an oven, and dry at a constant temperature of 120°C for 10 hours to obtain a dry powder; finally place it in a tube furnace, first vacuum, and then pass through N 2 , from room temperature to 450°C at a rate of 10°C / min, calcined for 6 hours, and cooled with the furnace body to obtain 15% V 2 o 5 and 0.5Li coated with 5% C 2 MnO 3 0.5Li(Mn 1 / 3 co 1 / 3 Ni 1 / 3 )O 2 , the sample is denoted as LMSSVC.

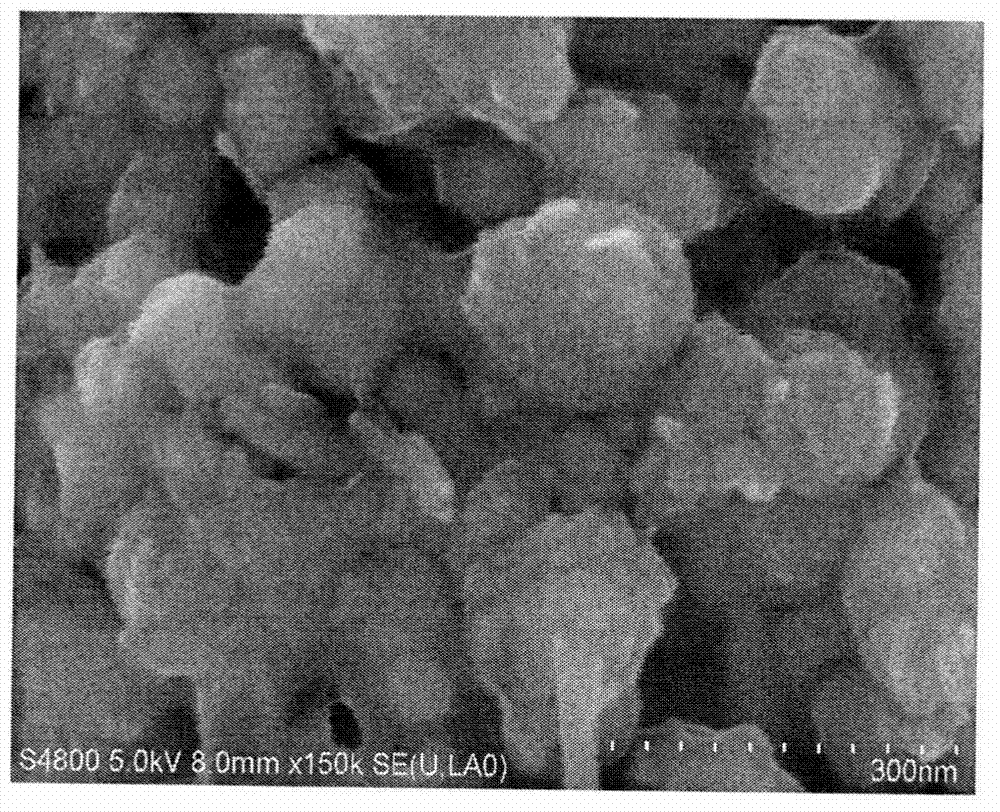

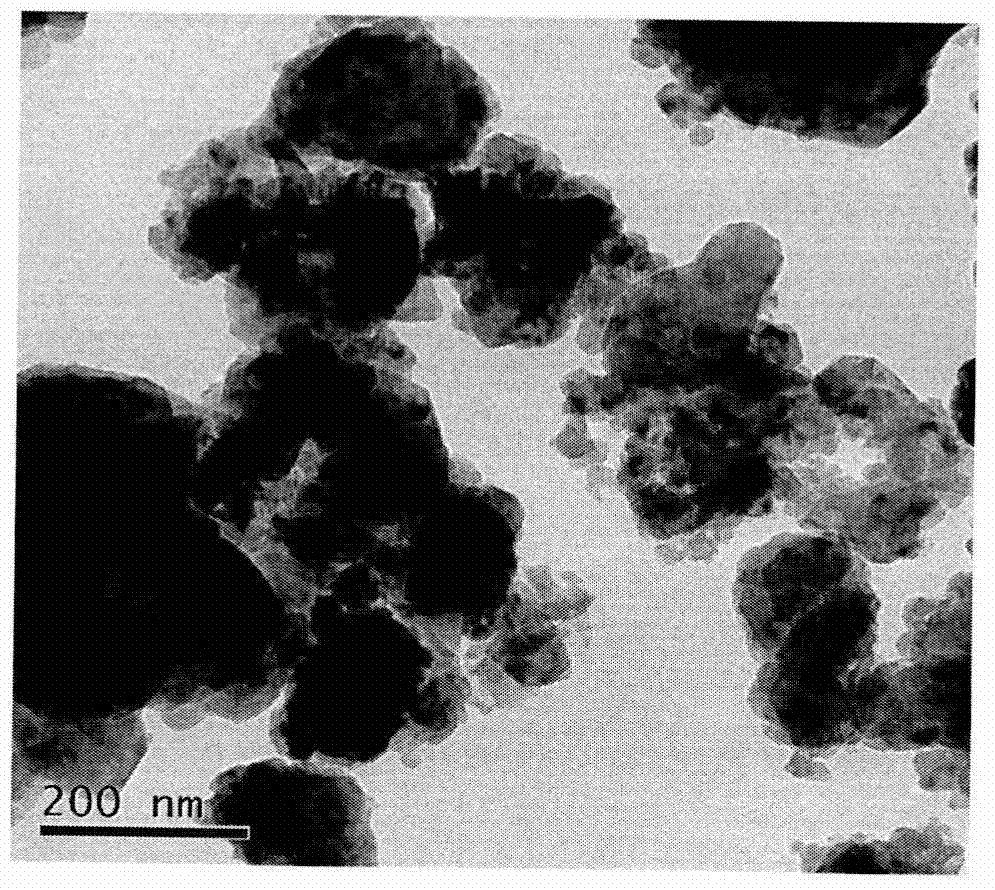

[0068] The present invention carries out SEM and TEM analysis to the product that embodiment obtains, and result is as follows figure 1 and figure 2 as shown, figure 1 for V 2 o 5 SEM images of lithium-rich manganese-based solid solution LMSSVC coated with / C hybrid layer, ...

Embodiment 2

[0072] Weigh 12.857g ammonium metavanadate, 7.125g sucrose and dissolve in 500ml deionized water, add 100g lithium-rich manganese-based solid solution 0.4Li 2 MnO 3 0.6Li(Mn 1 / 3 co 1 / 3 Ni 1 / 3 )O 2 , stir evenly, heat in an oil bath at 120°C until the water is evaporated to dryness, transfer to an oven, and dry at a constant temperature of 120°C for 10 hours, place the dried powder in a tube furnace, vacuumize, and pass through N 2 , was calcined from room temperature to 450°C at a rate of 10°C / min for 5h, and cooled naturally with the furnace to obtain 10% V 2 o 5 and 0.4Li coated with 3% C 2 MnO 3 0.6Li(Mn 1 / 3 co 1 / 3 Ni 1 / 3 )O 2 . According to the method of Example 1, its electrochemical performance was tested, and the irreversible capacity of the first charge and discharge was 51mAh / g, and the capacity retention rate was 85% after 50 cycles at 0.1C. The initial discharge capacities of 0.1C, 0.2C, 0.5C, 1C, 2C and 5C rates are 272, 238, 215, 189, 167 and 146mAh / g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com