High-nickel cathode material and preparation method thereof and lithium-ion battery

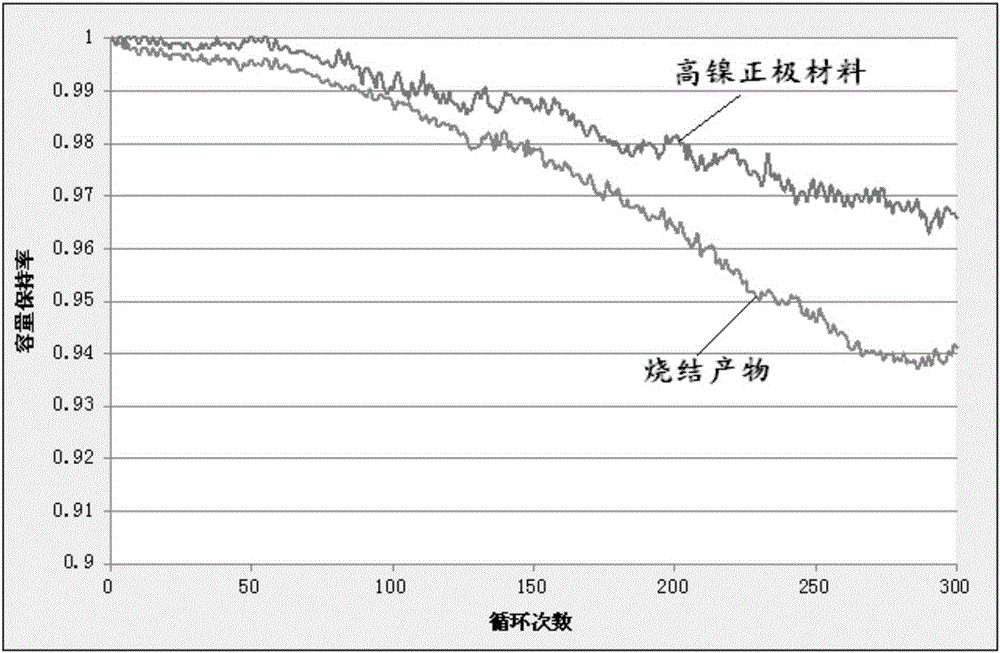

A positive electrode material and high-nickel technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as difficult processing, increased internal resistance of batteries, and delithiation reactions, so as to promote lithium ion conduction and reduce the content of lithium ions. The effect of alkali amount and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention provides a method for preparing a high-nickel positive electrode material described in the above technical solution, comprising the following steps:

[0050] 1), nickel-cobalt hydroxide is heat-treated to obtain an intermediate product, and the nickel-cobalt hydroxide is a compound shown in formula II:

[0051] Ni 1-x-y co x m y (OH) 2 Formula II;

[0052] In formula II, 0.00

[0053] 2), sintering the intermediate product and the lithium compound to obtain a sintered product, the amount of the lithium compound is such that the ratio of the total moles of nickel, cobalt and manganese to the moles of lithium is 1:(0.95~1.15);

[0054] 3), mixing the sintered product with a cobalt compound to obtain a mixture;

[0055] 4), heat-treating the mixture to obtain a high-nickel positive electrode material.

[0056] In the invention, the nickel-cobalt hydroxide is heat-treated to obtain an intermediate product. In the present in...

Embodiment 1

[0099] According to the molar ratio of Ni:Co:Mn being 0.80:0.10:0.10, nickel sulfate solution, cobalt sulfate solution and manganese sulfate solution are uniformly mixed to obtain a mixed solution; the metal ion concentration in the mixed solution is 1.0mol / L;

[0100] Use a peristaltic pump to add 5mol / L ammonia solution, 5mol / L sodium hydroxide solution and the mixed solution into the reactor to carry out coprecipitation reaction, control the temperature of the coprecipitation reaction to be 50°C, the pH value is 10.5, and the ammonia value is 10g / L, after the co-precipitation reaction is completed, the co-precipitation product obtained is subjected to solid-liquid separation, and the solid product obtained is washed and dried to obtain a chemical formula of Ni 0.8 co 0.1 mn 0.1 (OH) 2 nickel cobalt hydroxide;

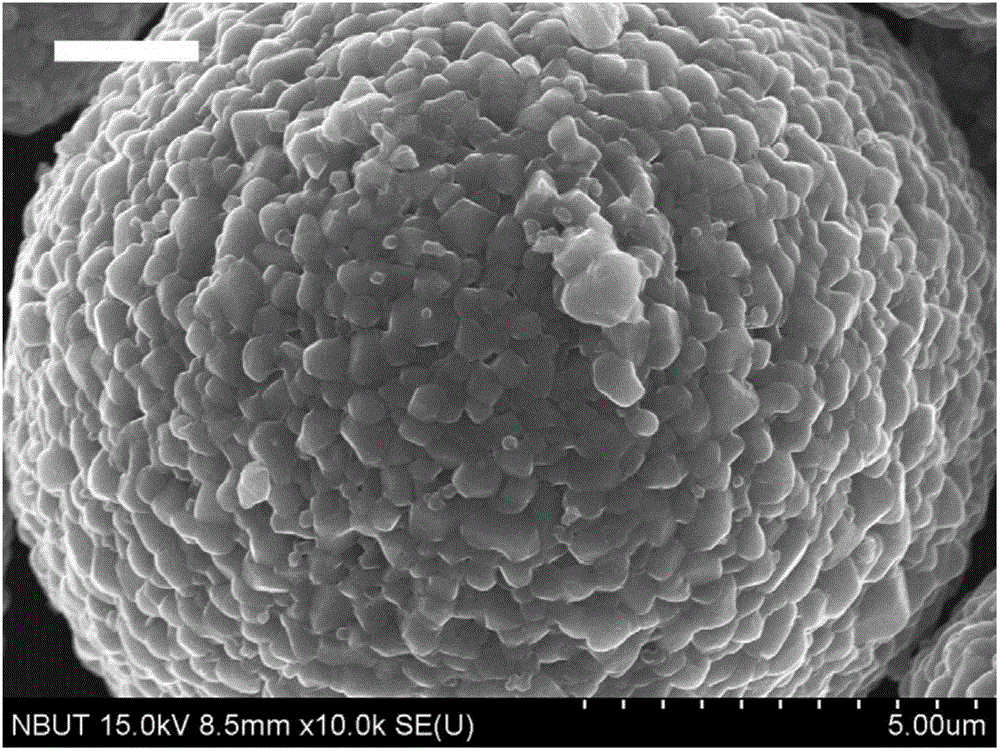

[0101] Under an air flow with an oxygen content of 60%, the nickel-cobalt hydroxide and lithium hydroxide were sintered at 780° C. for 10 h to obtain a sintered p...

Embodiment 2

[0111] According to the molar ratio of Ni:Co:Mn being 0.85:0.10:0.05, nickel sulfate solution, cobalt sulfate solution and manganese sulfate solution are uniformly mixed to obtain a mixed solution; the metal ion concentration in the mixed solution is 2.0mol / L;

[0112] Use a peristaltic pump to add 10mol / L ammonia solution, 3mol / L sodium hydroxide solution, 5mol / L zirconium nitrate solution and the mixed solution into the reaction kettle for coprecipitation reaction, and control the temperature of the coprecipitation reaction to be 40°C. The pH value is 11, and the ammonia value is 5g / L. After the co-precipitation reaction is completed, the obtained co-precipitation product is subjected to solid-liquid separation, and the obtained solid product is washed and dried to obtain a chemical formula of Ni0.85 co 0.10 mn 0.05 (OH) 2 nickel cobalt hydroxide;

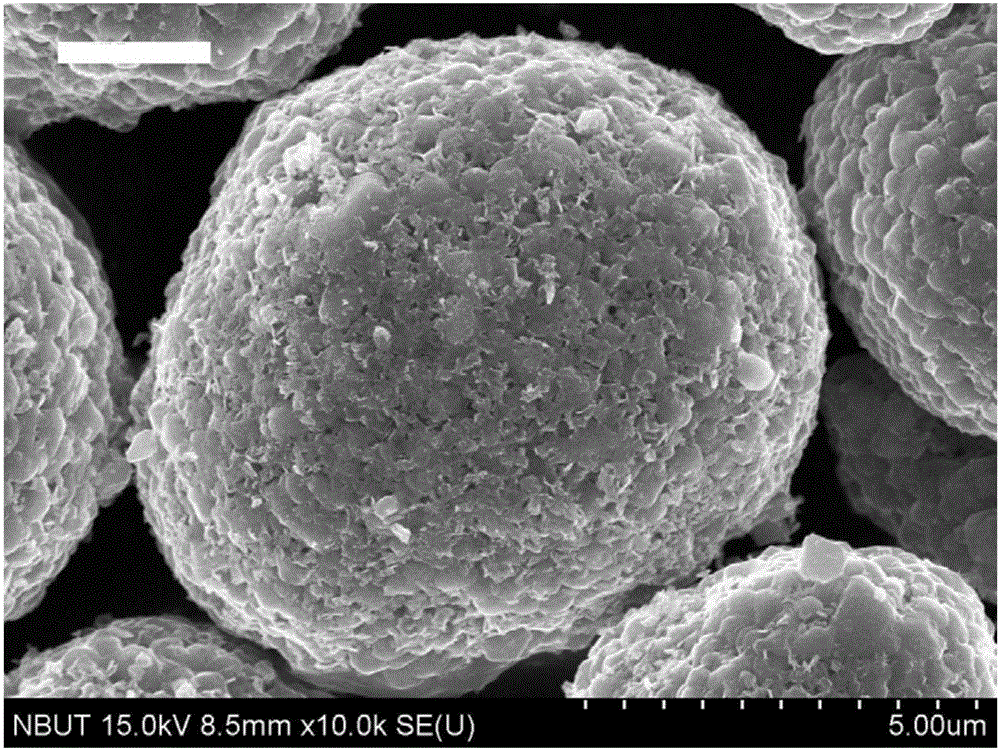

[0113] Under an air flow with an oxygen content of 90%, the nickel-cobalt hydroxide and lithium hydroxide were sintered at 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com