Automatic target scoring and speed measuring device and positioning and speed measuring method thereof

An automatic, target-surface technology, applied in the direction of targets, target indication systems, weapon accessories, etc., can solve the problems of complex signal processing algorithms, high cost of use, limited sensitivity, etc., to avoid trigonometric function calculations, low installation accuracy requirements, and simplified The effect of hardware and software structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

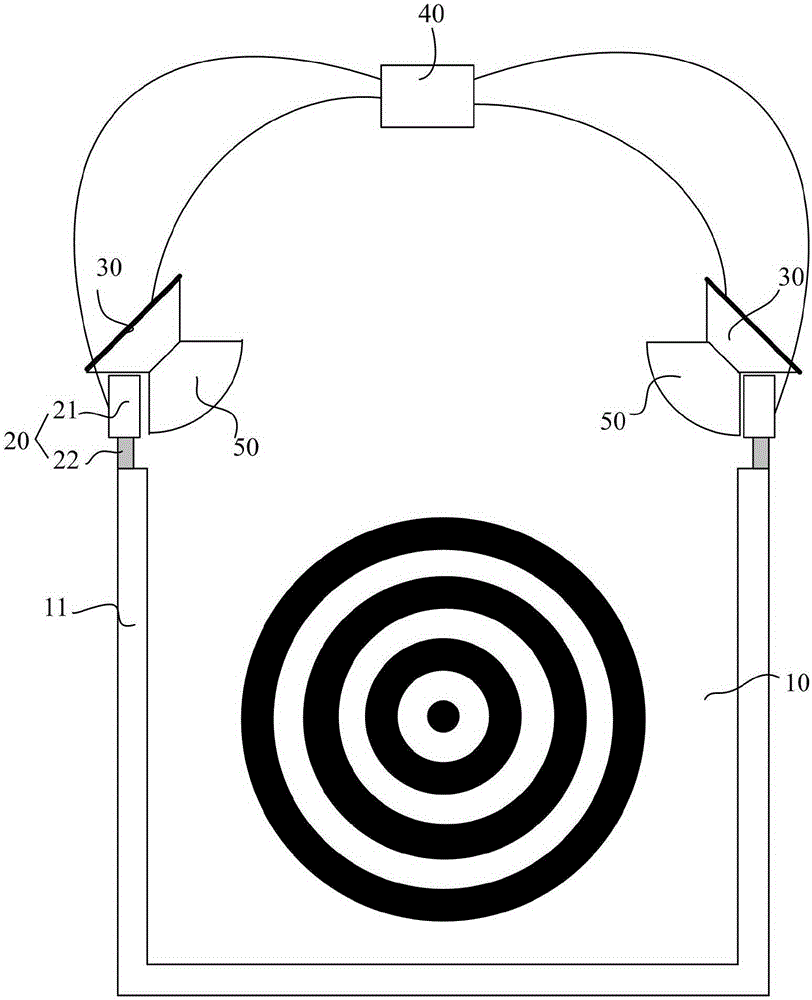

[0047] Such as figure 1 As shown, Embodiment 1 of the present invention provides an automatic target reporting device, which includes,

[0048] Target surface 10, on which target material and target paper are laid sequentially on the target surface 10;

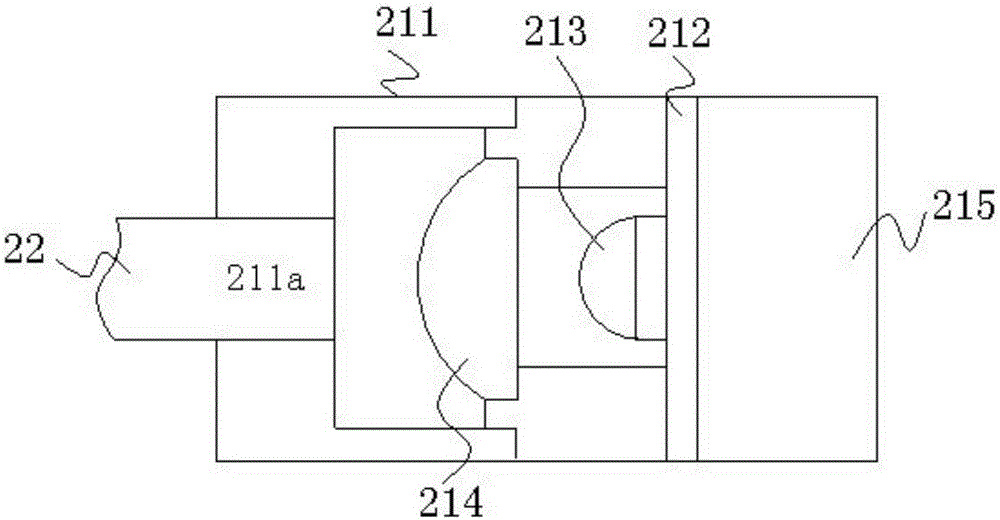

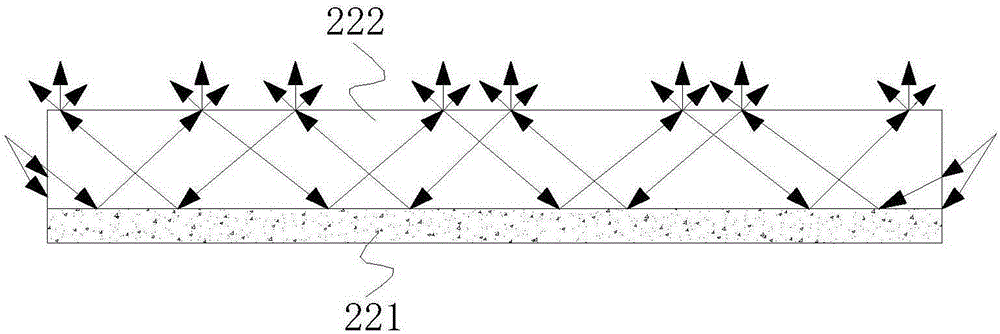

[0049] A linear continuous infrared background light source 20 is installed around at least three edges of the target surface 10;

[0050]At least two first-type optical sensors 30 connected to the main control board 40, the at least two first-type optical sensors 30 are respectively installed on the top corners of the target surface 10, so that the first-type optical sensors 30 can be The viewing range covers the entire target surface 10;

[0051] The main control board 40 is electrically connected with the first-type optical sensor 30, and is used to receive the data collected by the first-type optical sensor 30, and obtain the geometric coordinates of the impact point through analysis and calculation. The specific compos...

Embodiment 2

[0103] Embodiment 2 of the present invention such as Figure 14 Shown, a kind of automatic speed measuring device, it comprises,

[0104] Two target surfaces 10 arranged side by side;

[0105] Each target surface 10 is respectively provided with a linear continuous infrared background light source 20, and the linear continuous infrared background light source 20 is respectively installed around at least three edges of each target surface 10;

[0106] Each of the two ends of the linear continuous infrared background light source 20 is respectively connected with at least two first-type optical sensors 30 on the optical path, and the at least two first-type optical sensors 30 are respectively installed on the vertex of the target surface 10, so that The visible range of the first type of optical sensor 30 covers the entire target surface 10;

[0107] The second-type optical sensor 60 installed directly above each target surface 10 also has a visible range covering the entire t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Opening angle | aaaaa | aaaaa |

| Viewing angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com