Open pit mining method for gentle tip ore body

An open-pit mining and gently inclined technology, which is applied in open-pit mining, earthwork drilling, special mining, etc., can solve the problems of the length of the working line being limited by the size of the stope, the difficulty of blasting construction technology, and the large amount of initial development work. , to achieve the effect of improving blasting effect, avoiding technical difficulties in blasting construction, and reducing transportation and lifting work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

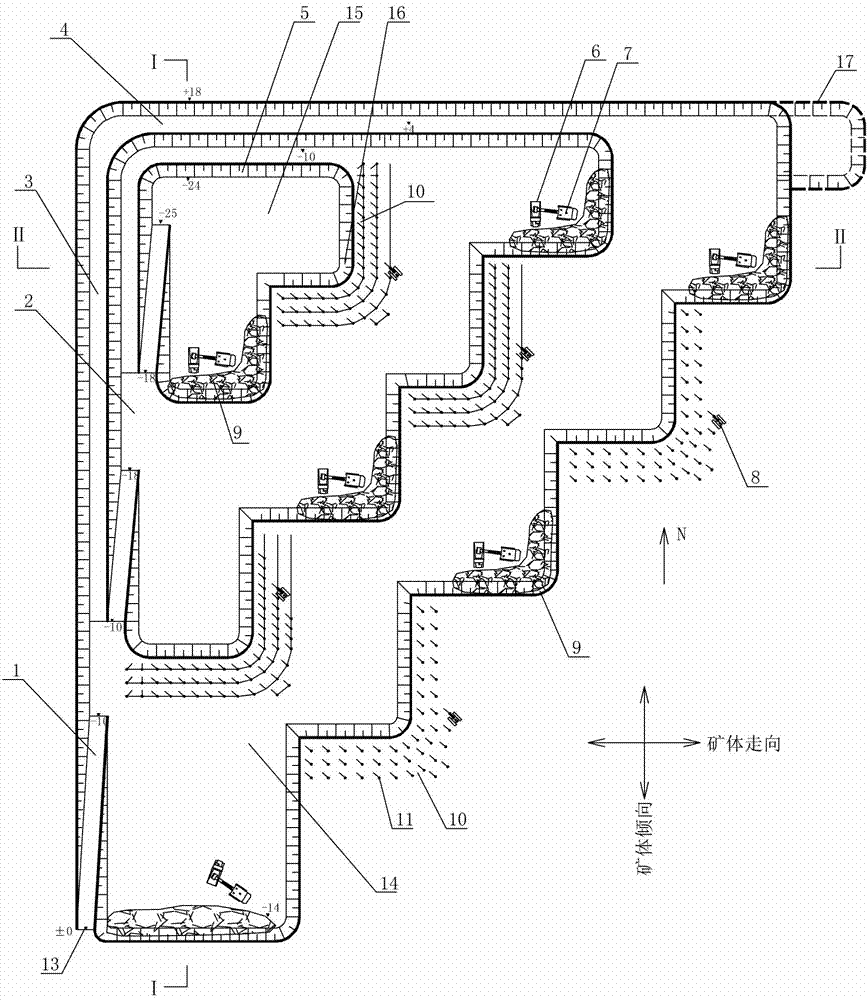

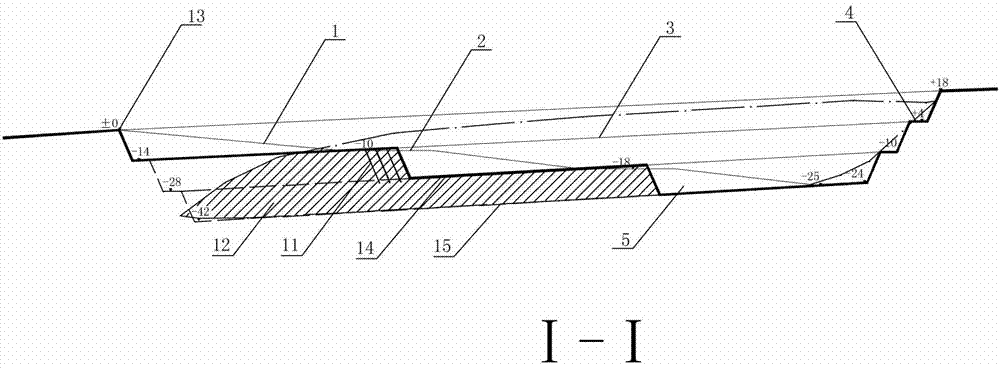

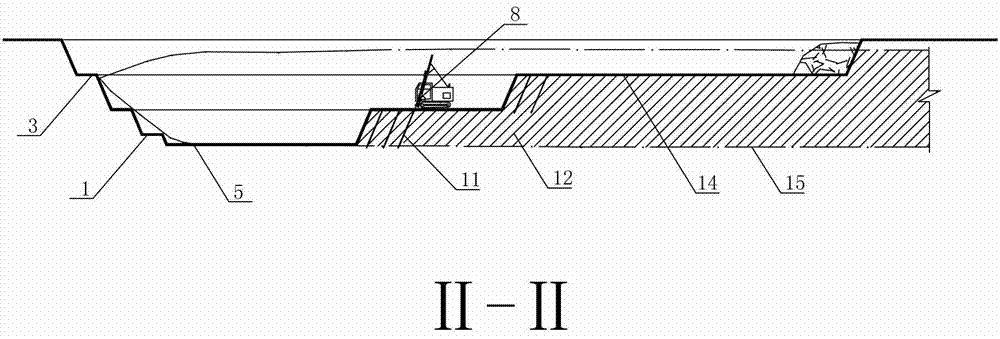

[0038] Such as Figure 1 to Figure 5 As shown, in the open-pit mining method of a gently inclined ore body described in this embodiment, the ore body is in an east-west direction, inclined to the south, and the inclination angle is 4 degrees. A plurality of inclined transportation channels 1 are arranged in the stope, and a horizontal buffer platform 2 with a length of at least 30 m is arranged between adjacent inclined transportation channels 1. The transportation platform 3 and the horizontal transportation platform 4 along the direction of the ore body, the excavator 7 and the transportation vehicle 6 are located in the shovel loading area 9 of the "┏"-shaped opening ditch 5; the excavator 7 excavates the blasted ore or rock and loads it into the In the car 6, after the transport car 6 is filled with ores or rocks, it is transported along the mining stratified inclined floor 14, the horizontal buffer platform 2 and the inclined transport channel 1, and then transported out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com