A wave rotor cascade refrigeration system and its working method

A technology of refrigeration system and wave rotor, which is applied in the field of wave rotor cascade refrigeration system, can solve the problems that hinder the wide application of R718 refrigerant, and achieve the effects of excellent liquid-filled operation performance, low speed, and easy development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

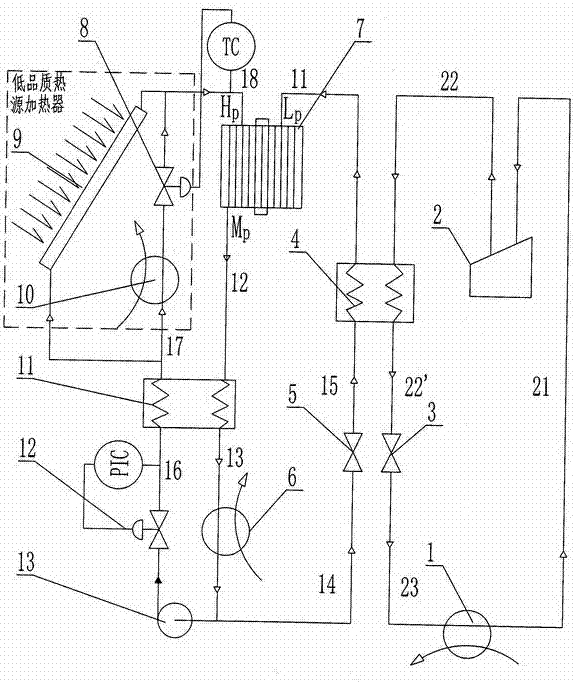

[0019] Embodiment 1 A wave rotor cascade refrigeration system utilizing solar energy as a heat source.

[0020] figure 1 A solar wave rotor cascade refrigeration system is shown. In the figure, the solar wave rotor cascade refrigeration system includes an evaporator 1, a low temperature compressor 2, a low temperature throttle valve 3, a condensation evaporator 4, a high temperature throttle valve 5, a cooler 6, a wave rotor 7, a temperature regulating valve 8, Heat collector 9, electric heater 10, regenerator 11, pressure regulating valve 12, booster pump 13. The outlet of the evaporator 1 is connected to the inlet of the cryogenic compressor 2, the outlet of the cryogenic compressor 2 is connected to the hot end inlet of the condensing evaporator 4, and the hot end outlet of the condensing evaporator 4 is connected to the inlet of the low temperature throttle valve 3, The outlet of the low-temperature throttle valve 3 is connected to the inlet of the evaporator 1; the outl...

Embodiment 2

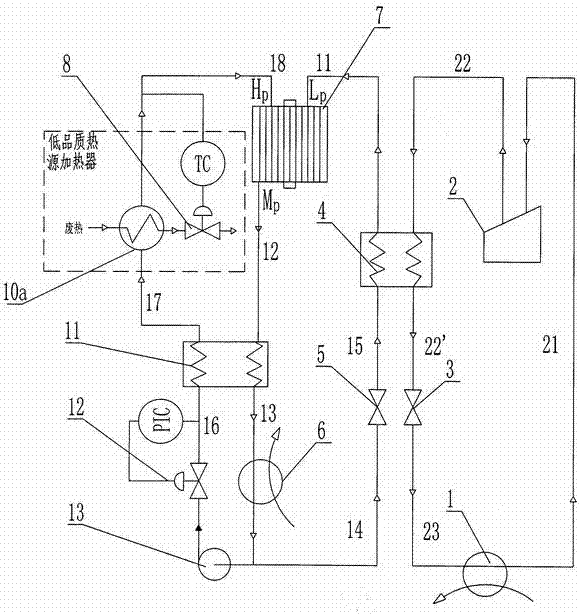

[0023] Example 2 A wave rotor cascade refrigeration system using waste heat as a heat source.

[0024] figure 2 A waste heat wave rotor cascade refrigeration system is shown. figure 2 and figure 1 The difference is that: the outlet of the regenerator 11 is connected to the inlet of the waste heat heater 10a, and the outlet of the waste heat heater 10a is connected to the driving steam inlet H of the rotor 7 P connect. The rest of the principles and equipment arrangement remain basically the same.

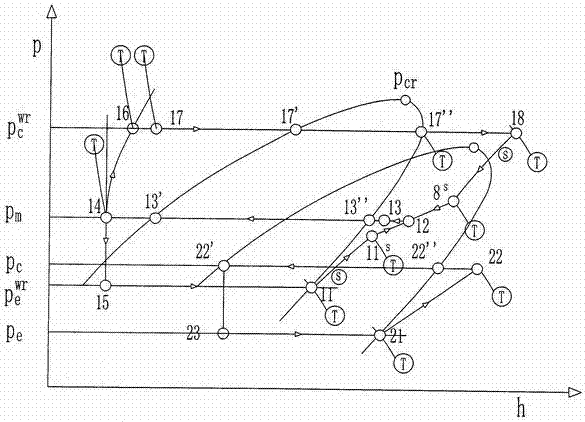

[0025] The low-temperature refrigerant absorbs heat at a constant temperature and constant pressure in the evaporator 1 to achieve refrigeration, becomes saturated steam and enters the low-temperature compressor 2, and the formed high-temperature and high-pressure gas passes through the condensing evaporator 4 and then passes through the low-temperature throttle valve in a saturated liquid state to reduce temperature and pressure Enter evaporator 1; outlet M of pressurized ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com