A kind of graphite mold and preparation method thereof

A technology of graphite mold and graphite emulsion, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve problems such as easy breakage of tail, idle graphite equipment or waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

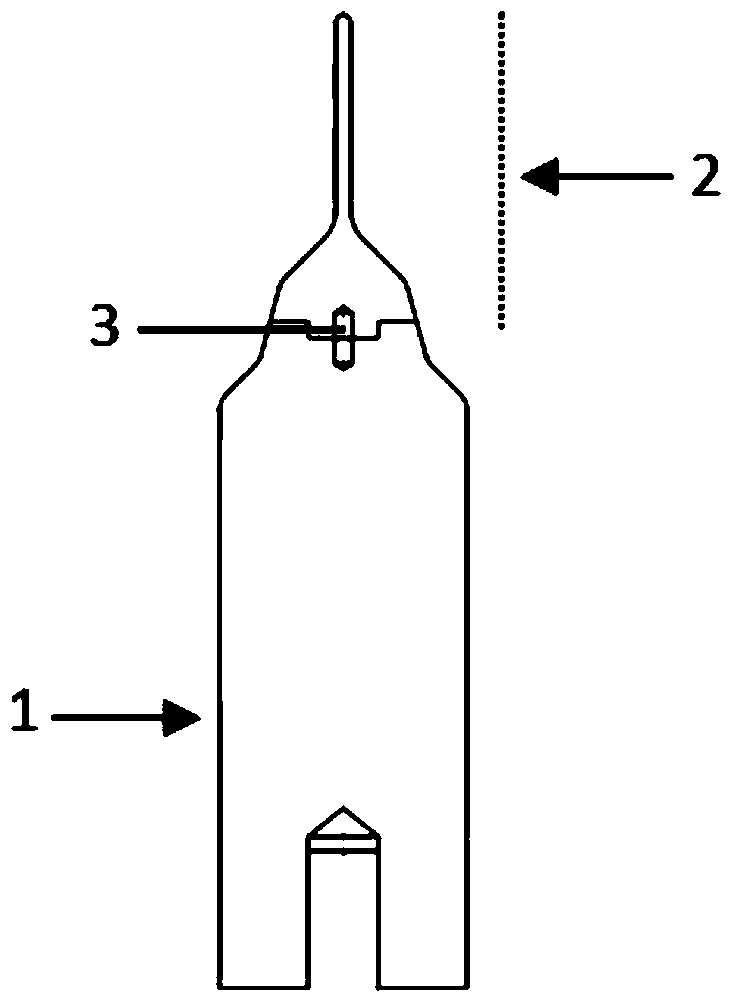

[0025] The present invention also provides a preparation method for the above-mentioned graphite mould, comprising: coating the graphite emulsion solution on the contact surface of the mold main body (1) and the detachable part (2), and then combining the mold main body (1) with The detachable part (2) is connected by a connecting block (3), and after drying, it is polished to obtain a graphite mold; the end of the detachable part (2) not in contact with the mold main body (1) is in the shape of a thin neck.

[0026] The graphite emulsion solution is coated on the contacting surface of the mold main body (1) or the detachable part (2); wherein the coating method is a method well known to those skilled in the art, and there is no special limitation, the present invention Spraying or brushing is preferred. The mass ratio of graphite milk to solvent in the graphite milk solution is preferably 1:(1-3), more preferably 1:(2-3). The graphite emulsion in described graphite emulsion ...

Embodiment 1

[0033] see figure 1 , mix the water-based graphite emulsion and water evenly according to the mass ratio of 1:2 to obtain the water-based graphite emulsion solution; evenly paint the water-based graphite emulsion solution on the connecting contact surface between the mold main body (1) and the detachable part (2), and then Put the connecting block (3) with a diameter of 24mm into the main body of the mold (1), connect the detachable part (2) with the main body of the mold through threads and tighten it, and after the water-based graphite emulsion solution is dried, use 320 mesh, 800 mesh, 1200 mesh Grind the surface of the mold with 3M SiC sandpaper of mesh and 1500 mesh, from coarse to fine, and finally polish the surface with newspaper or the back of the sandpaper until it is bright, and obtain a graphite mold.

[0034] There are almost no connection traces at the joint between the mold main body (1) and the detachable part (2) of the graphite mold.

Embodiment 2

[0036]Mix the water-based graphite emulsion and water evenly according to the mass ratio of 1:1 to obtain the water-based graphite emulsion solution; evenly paint the water-based graphite emulsion solution on the connecting contact surface between the mold main body (1) and the detachable part (2), and then apply the The connection block (3) with a diameter of 10 mm is placed in the mold body (1), and the detachable part (2) is connected to the mold body by threads and tightened. and 1500-mesh 3M SiC sandpaper to polish the surface of the mold, the sandpaper is from coarse to fine, and finally polish the surface with newspaper or the back of the sandpaper until it is bright, to obtain a graphite mold.

[0037] No connection traces can be seen at the joint between the mold main body (1) and the detachable part (2) of the graphite mold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com