Feeding machine with hopper convenient to replace and used for color master batch processing and using method of feeding machine

A technology of color masterbatch and feeding machine, which is applied in packaging and other directions, can solve the problems of difficult control of material output, difficult control of material volume, single feeder, etc., to improve bagging efficiency, convenient operation, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

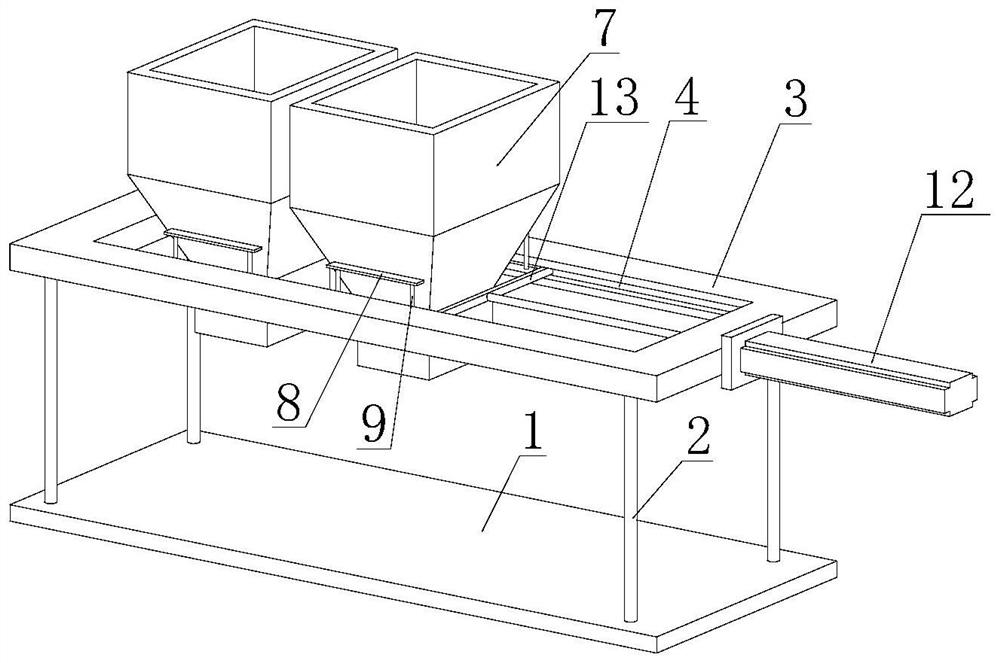

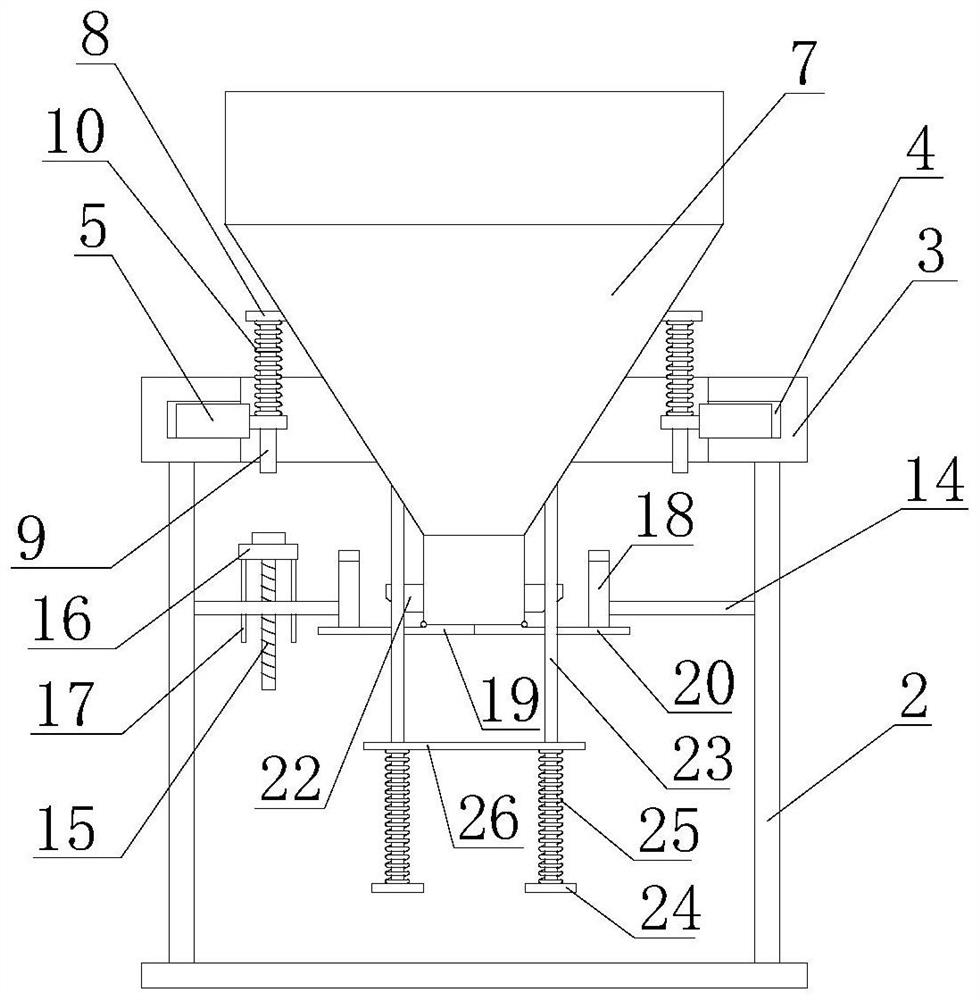

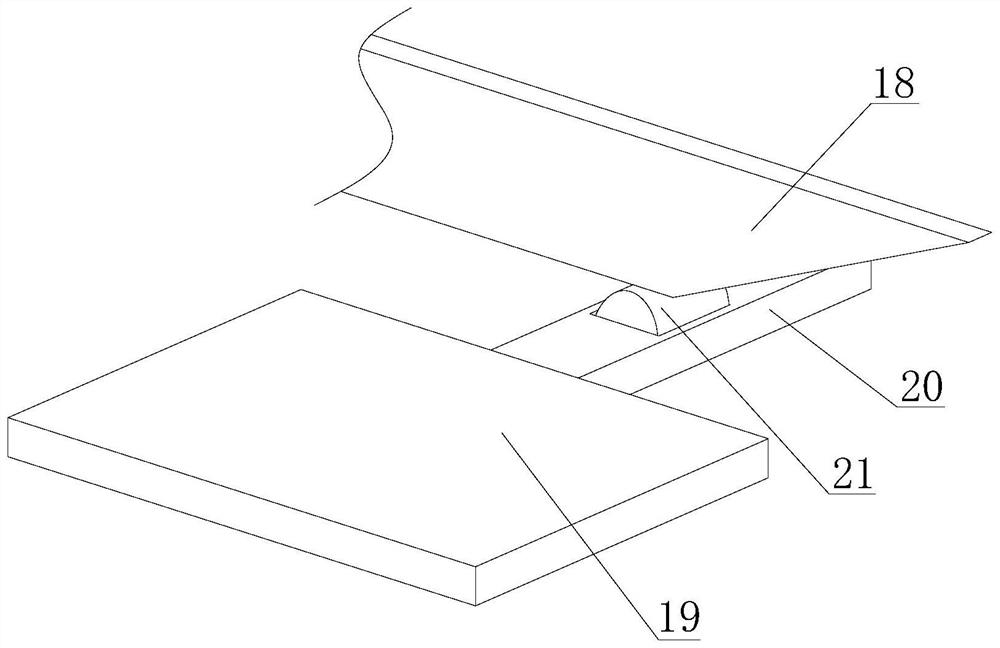

[0027] like Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: a feeder for color masterbatch processing that is convenient for changing hoppers, comprising a bottom plate 1, and the top four corners of the bottom plate 1 are fixedly connected with supporting legs 2, and the four supporting legs 2 are A support frame 3 is fixedly connected between the tops, and the inner walls of the two sides of the support frame 3 are provided with chute 4. The interior of the two chute 4 is slidably connected with a slide bar 5, and the two slide bars 5 are close to each other on one side. A support bar 6 is fixedly connected to the two support bars 6 and two bins 7 are detachably connected, and a No. 2 connecting plate 14 is fixedly connected between the two supporting legs 2 on the same side, and the two No. 2 connecting plates 14 are mutually connected. A trapezoidal extrusion plate 18 is fixedly connected in the middle of the close side, the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com