Fireproof roller shutter door surface pattern forming processing equipment and forming process thereof

A molding processing and rolling door technology, which is applied in decorative arts, embossed decorations, etc., can solve the problems of affecting processing speed, single function, and high defect rate of patterns and patterns, so as to improve the cleanliness, improve stability and fluency, and ensure The effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

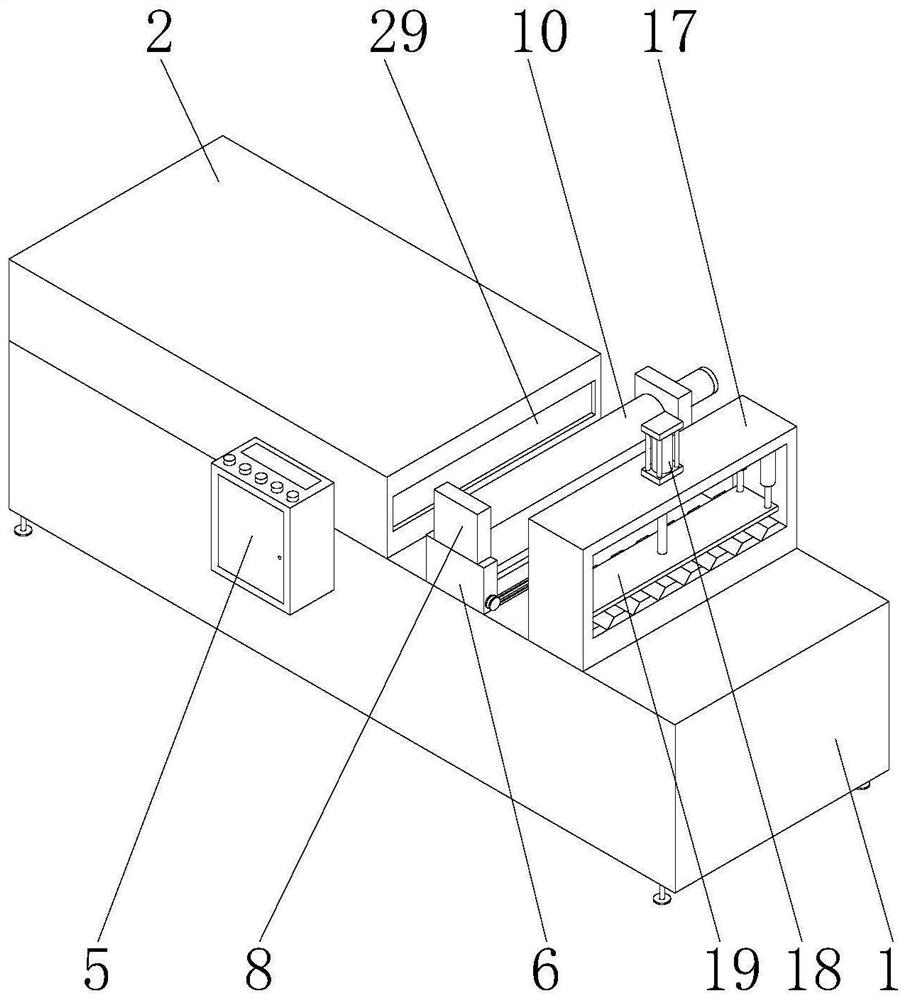

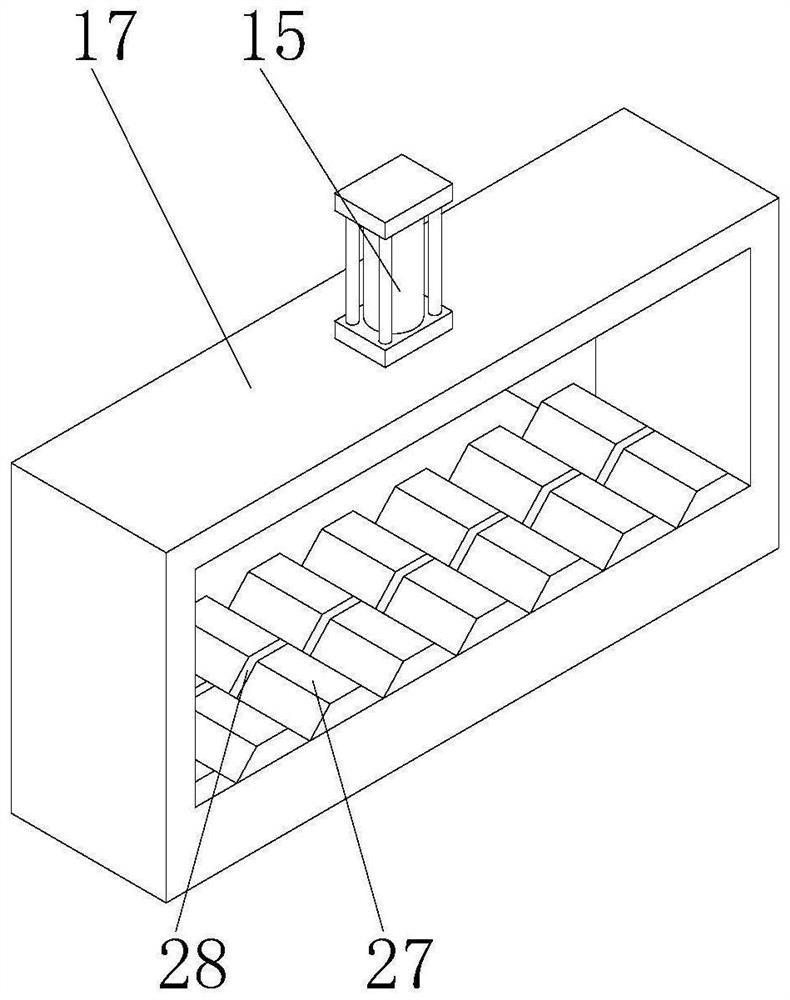

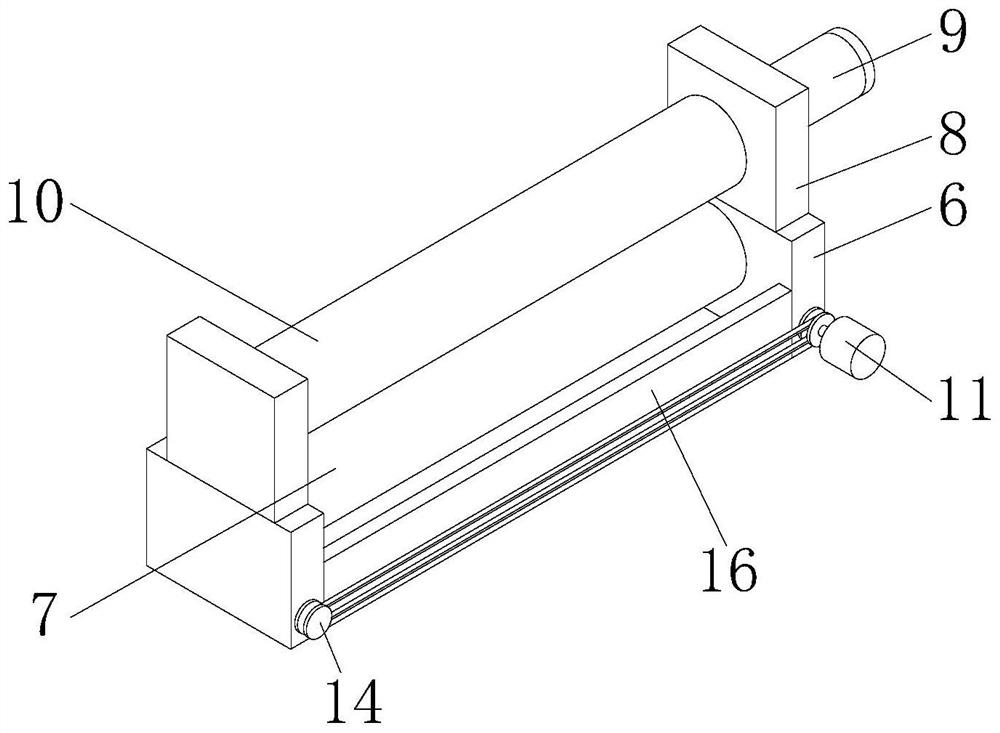

[0042] like Figure 1-9 As shown in the figure, a fireproof rolling shutter door surface pattern forming processing equipment includes a base 1, a conveying cover 2 is fixedly connected to the left side of the top of the base 1, and a plurality of conveying wheels 3 are arranged on the top and bottom of the inner cavity of the conveying cover 2. The conveying cover 2. The top and bottom of the left side of the inner cavity are fixedly connected with the cleaning component 4, the front side of the base 1 is fixedly connected with the control box 5, and the front and rear sides of the top of the base 1 are fixedly connected with a fixed shell 6, two fixed shells 6 An embossed lower roller 7 is arranged between the opposite sides, the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com