High-temperature-resistant microalloy high-carbon steel 82B wire rod and preparation method thereof

A micro-alloy and high-carbon steel technology, applied in the manufacture of converters, etc., can solve problems that require careful purchase of equipment and design parameters, low relaxation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

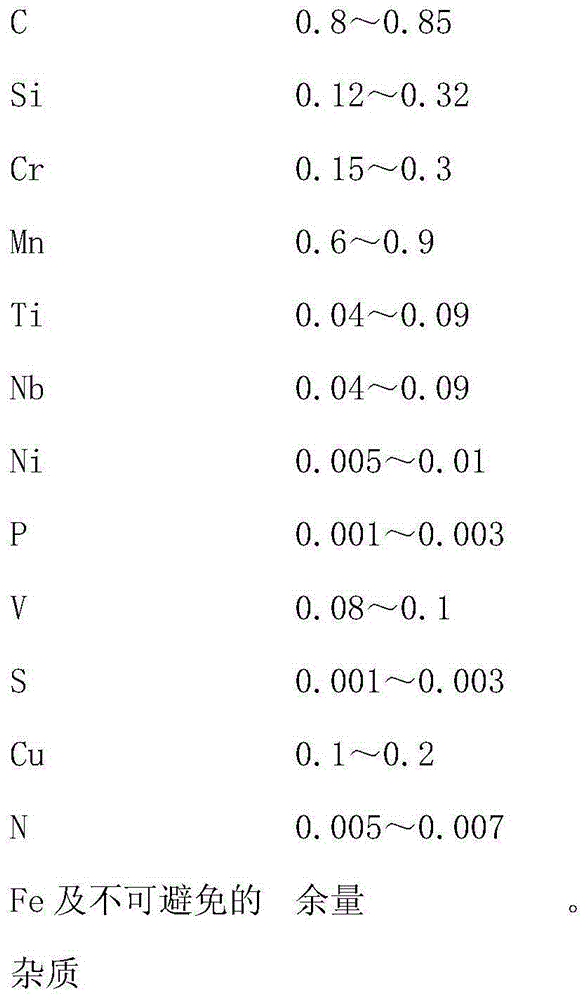

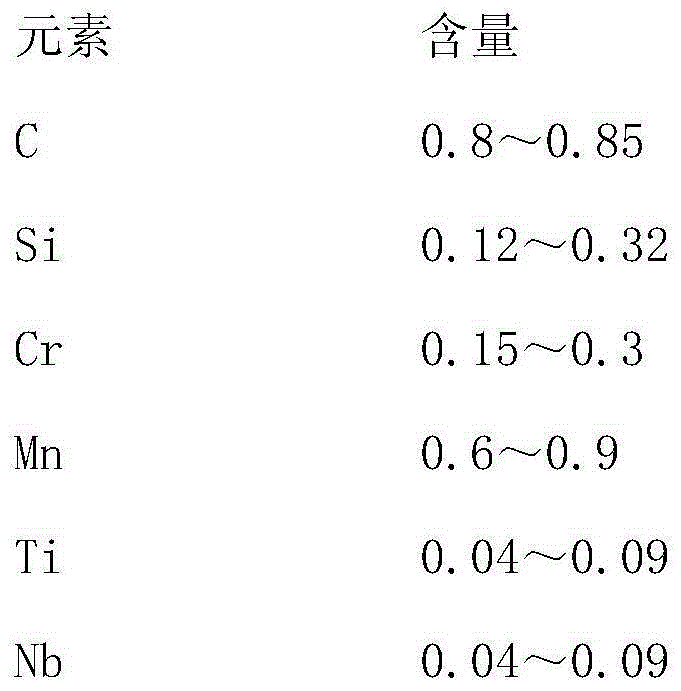

[0016] A high-temperature resistant micro-alloyed high-carbon steel 82B wire rod, the innovation of the present invention lies in: including the following components mixed by weight percentage:

[0017]

[0018]

[0019] The preparation method of the above-mentioned high-temperature resistant micro-alloyed high-carbon steel 82B wire rod comprises the following steps:

[0020] (1) Converter smelting micro-alloyed molten steel, using silicon-calcium deoxidation, the dosage is 150 kg / furnace, the tapping temperature is 1520-1580 degrees Celsius, and the smelting time is 30-35 minutes;

[0021] (2) In the initial stage of secondary refining, lime is used to control the alkalinity to 1.0-1.6, and the dosage is 1000 kg / furnace. In the mid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com