Rare-earth containing composite modificator suitable for Sn-P bronze alloy

A tin-phosphor bronze and rare earth composite technology is applied in the field of rare earth-containing composite modifiers, which can solve the problems of coarse dendrites in the as-cast structure and serious Sn segregation, and achieve the effects of refining the structure, reducing the segregation of Sn elements, and improving the uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

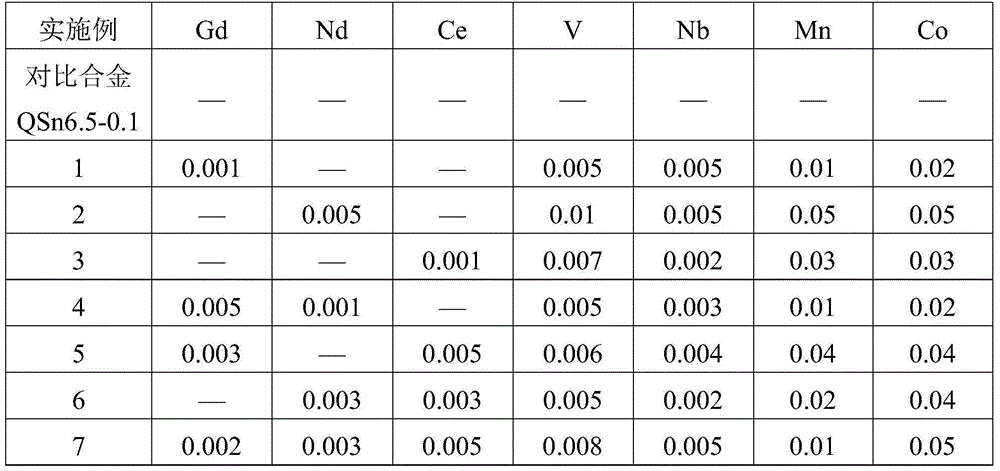

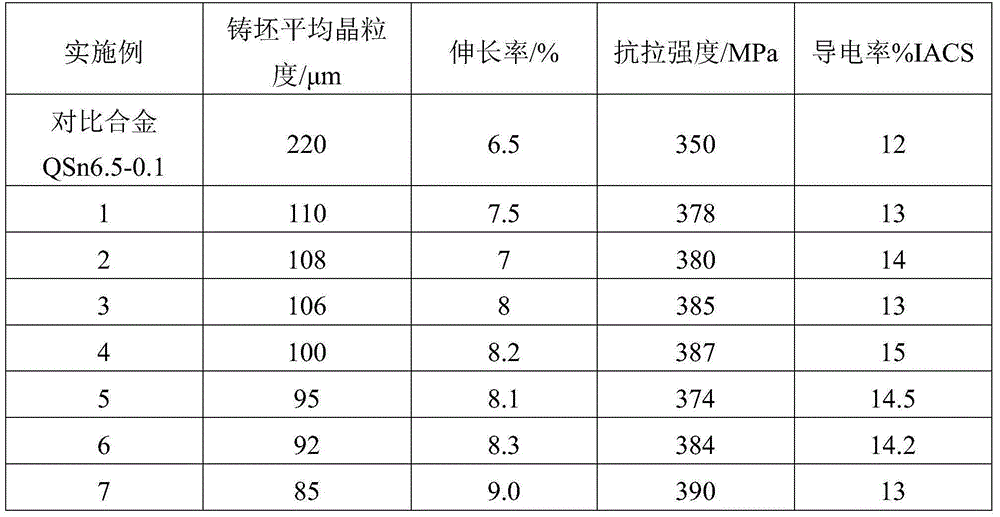

[0017] Example 1-7: Add the modifier of the present invention to the QSn6.5-0.1 tin phosphor bronze alloy. The weight percent composition of QSn6.5-0.1 is: Sn: 6.0-7.0%, P: 0.05-0.15%, and Cu is the balance. The processing technology of tin-phosphorus bronze alloy (QSn6.5-0.1) is batching→smelting→adding rare earth-containing compound modifier→horizontal continuous casting→face milling→cold rolling billet→annealing→pickling→medium rolling→annealing→acid Washing→finish rolling→stress relief annealing→pickling→tension bending straightening→separate shearing and storage.

[0018] The smelting process uses an intermediate frequency induction furnace and corresponding horizontal continuous casting equipment. First, electrolytic copper and electrolytic cobalt are melted, then at least one of Cu-Gd, Cu-Nd, and Cu-Ce is added, and then Cu-Nb, Cu-Mn, Cu-V, then add copper-phosphorus intermediate alloy, stir for 10-20 minutes, add pure tin after holding for 20-30 minutes, then carry ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com