Coating material for automobile braking system and preparation method thereof

A technology for automotive braking systems and coating materials, applied in coatings and other directions, can solve problems such as not having a high friction coefficient, achieve the effects of increasing the initial pressure-contact area, reducing failure rates, balancing and adjusting parallelism errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

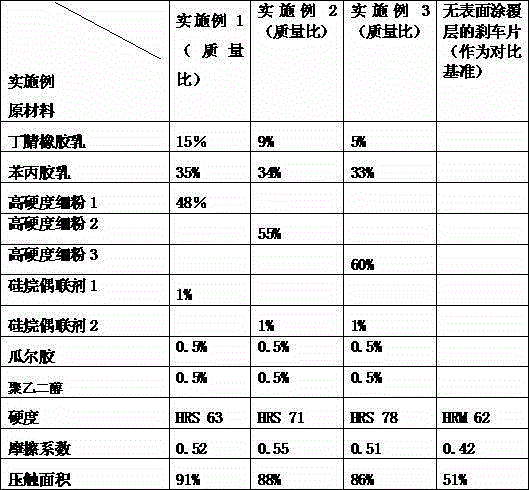

[0024] Mix evenly according to the material ratio in the ratio table, coat on the surface of the reference brake pad, and test and compare the surface hardness, initial pressure contact area, and initial friction coefficient.

[0025] Matching table and test data

[0026]

[0027] Raw materials and technical specifications used in the above table: nitrile rubber latex, nitrile rubber solid content 40%-55%; styrene-acrylic latex, styrene-acrylate emulsion solid content 40%-50%; high hardness fine powder 1, three Aluminum oxide fineness 800 mesh; high hardness fine powder 2, zirconia fineness 600 mesh; high hardness fine powder 3, silica fineness 800 mesh; silane coupling agent 1, KH550 type; silane coupling agent 2, KH570 type; guar gum hydroxypropyl trimethyl ammonium chloride HV high viscosity type; polyethylene glycol, HO(CH?CH?O)nH, molecular weight 200~600.

[0028] The comparison test results show that after coating the material of the present invention, the surface h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com