Montmorillonite/polyaniline nano flame-retardant polystyrene composite material

A composite material and nano flame retardant technology, applied in the field of polymer flame retardant, can solve the problems of poor dispersion, easy agglomeration, damage to processing performance, etc., and achieve the effects of improving agglomeration, alleviating layer-by-layer accumulation and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

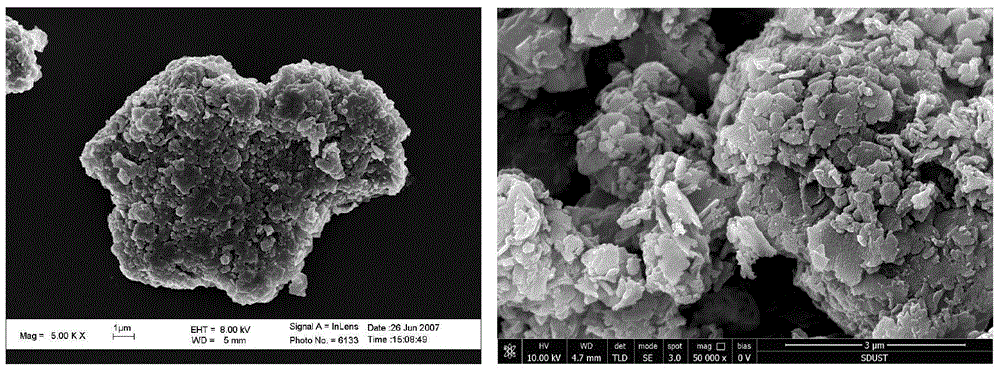

[0029] A kind of montmorillonite / polyaniline nano flame-retardant polystyrene composite material, its preparation method comprises the following steps:

[0030] (1) Add 5 mol of sodium dodecylbenzene sulfonate into 5 L of water, stir to dissolve and form a modifier solution.

[0031] (2) 50g of montmorillonite was added to the above solution, after ultrasonic dispersion for 6h, stirring and reacting for 48h to obtain a chemically modified montmorillonite suspension;

[0032] (3) Add 5g (0.0538mol) of aniline monomer to the above-mentioned chemically modified montmorillonite suspension, stir and disperse by ultrasonic waves;

[0033] (4) Add 0.269mol ammonium persulfate to the above-mentioned dispersion liquid, stir and react at room temperature for 12 hours, and prepare the montmorillonite / polyaniline nanocomposite;

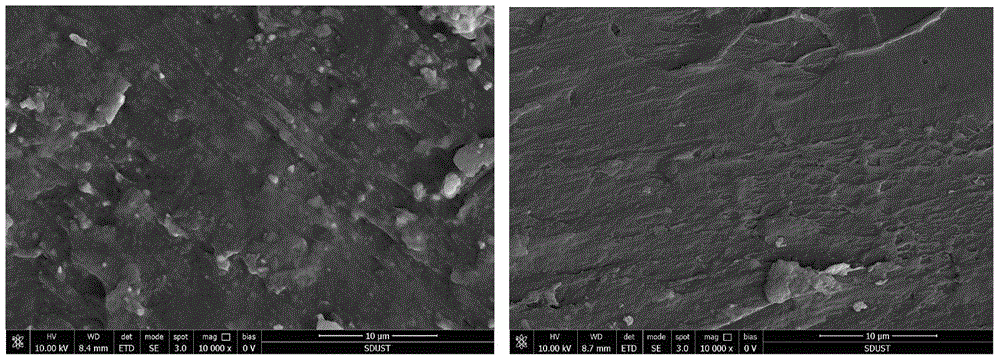

[0034] (5) Put 1 part of montmorillonite / polyaniline nanocomposite prepared in step (4) and 99 parts of general polystyrene resin (PG-383, purchased from Taiwan...

Embodiment 2

[0043] A kind of montmorillonite / polyaniline nano flame-retardant polystyrene composite material, its difference with embodiment 1 is that the sodium dodecylbenzene sulfonate of 5mol in step (1) becomes 2.5mol hexadecyl Trimethylammonium bromide, the quality of montmorillonite changed from 50g to 40g, 0.269mol ammonium persulfate into 0.1076mol potassium persulfate, montmorillonite / polyaniline nanocomposite changed from 1 part to 2 parts, general poly The styrene resin becomes 98 parts.

Embodiment 3

[0045] A kind of montmorillonite / polyaniline nano flame-retardant polystyrene composite material, its difference with embodiment 1 is that the sodium dodecylbenzene sulfonate of 5mol in step (1) becomes 1.5mol polystyrene sulfonate Sodium acid, the quality of montmorillonite changed from 50g to 30g, 0.269mol ammonium persulfate into 0.1614mol anhydrous ferric chloride, montmorillonite / polyaniline nanocomposite changed from 1 part to 3 parts, general polyphenylene Vinyl resin becomes 97 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com